Cold transfer printing method for viscose fabric

A technology of cold transfer printing and viscose fiber, which is applied in the direction of transfer printing, transfer printing, rotary printing machine, etc., and can solve the problems of pattern bleeding on the front of the fabric, affecting product quality, and background penetration of the fabric, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0015] The device adopted in the viscose fabric cold transfer printing method of the present embodiment is the transfer printing device of the cold transfer printing machine disclosed in Chinese patent document CN201669968U. The specific method is: pass the viscose fiber fabric and the transfer printing paper through the transfer printing device respectively The leading roller enters the interlayer between the ring-shaped blanket belt of the transfer printing device and the main pressure roller, and under the action of five pressure rollers and the main pressure roller, the dye pattern on the transfer printing paper is transferred to the viscose fabric.

[0016] The pressures of the five pressure rollers are set to 200kg, 500kg, 1000kg, 2000kg and 3500kg in sequence.

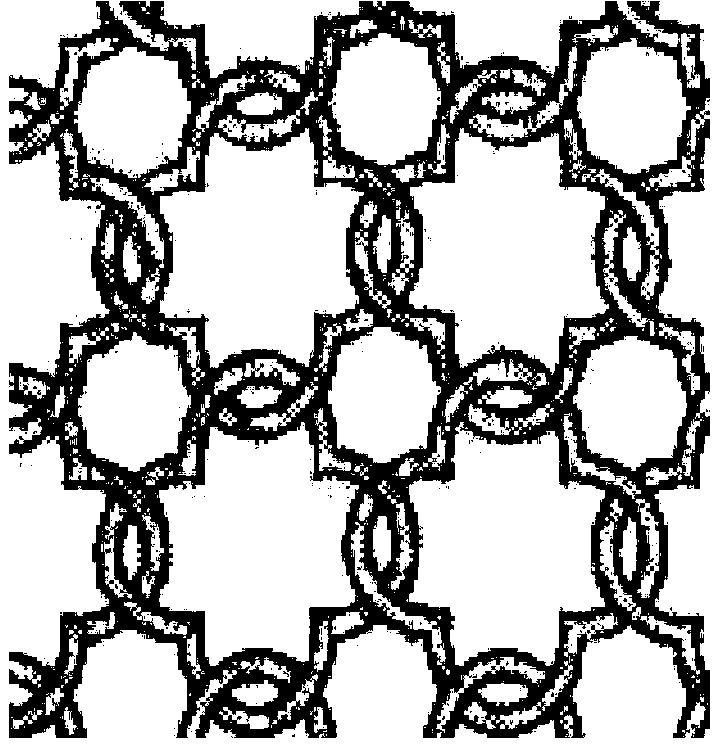

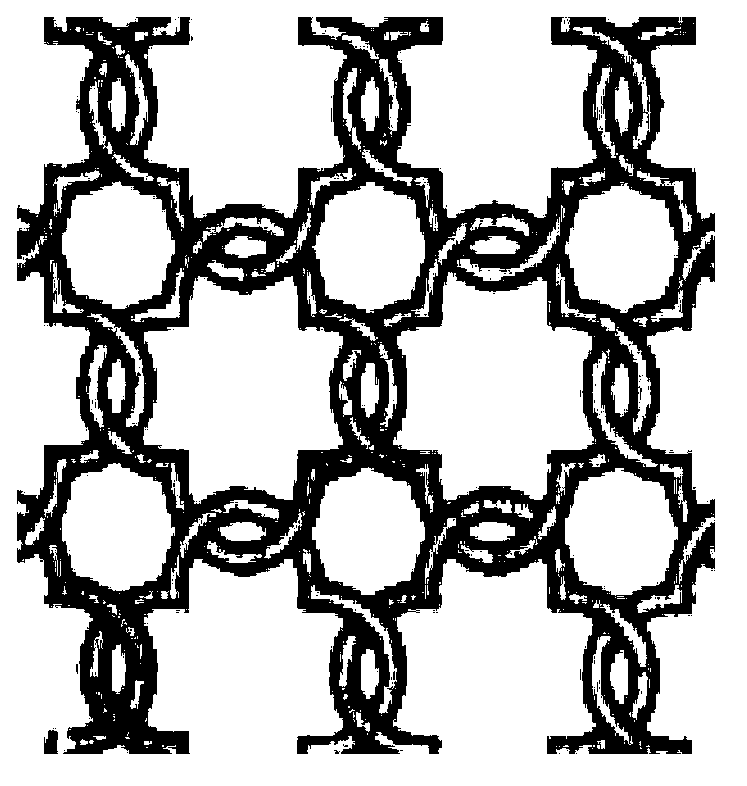

[0017] The effect figure of the viscose fabric after adopting the method transfer printing of the present embodiment is shown in image 3 and Figure 4 ,Depend on image 3 It can be seen that the pattern lines...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com