Low-position straight heating machine

A direct heat machine, low-level technology, applied in the field of heat exchange, can solve the problems of not being able to use medium and high temperature wastewater heat exchangers, being unable to install, and not being well resolved

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0029] The present invention will be described in further detail below in conjunction with the accompanying drawings and embodiments.

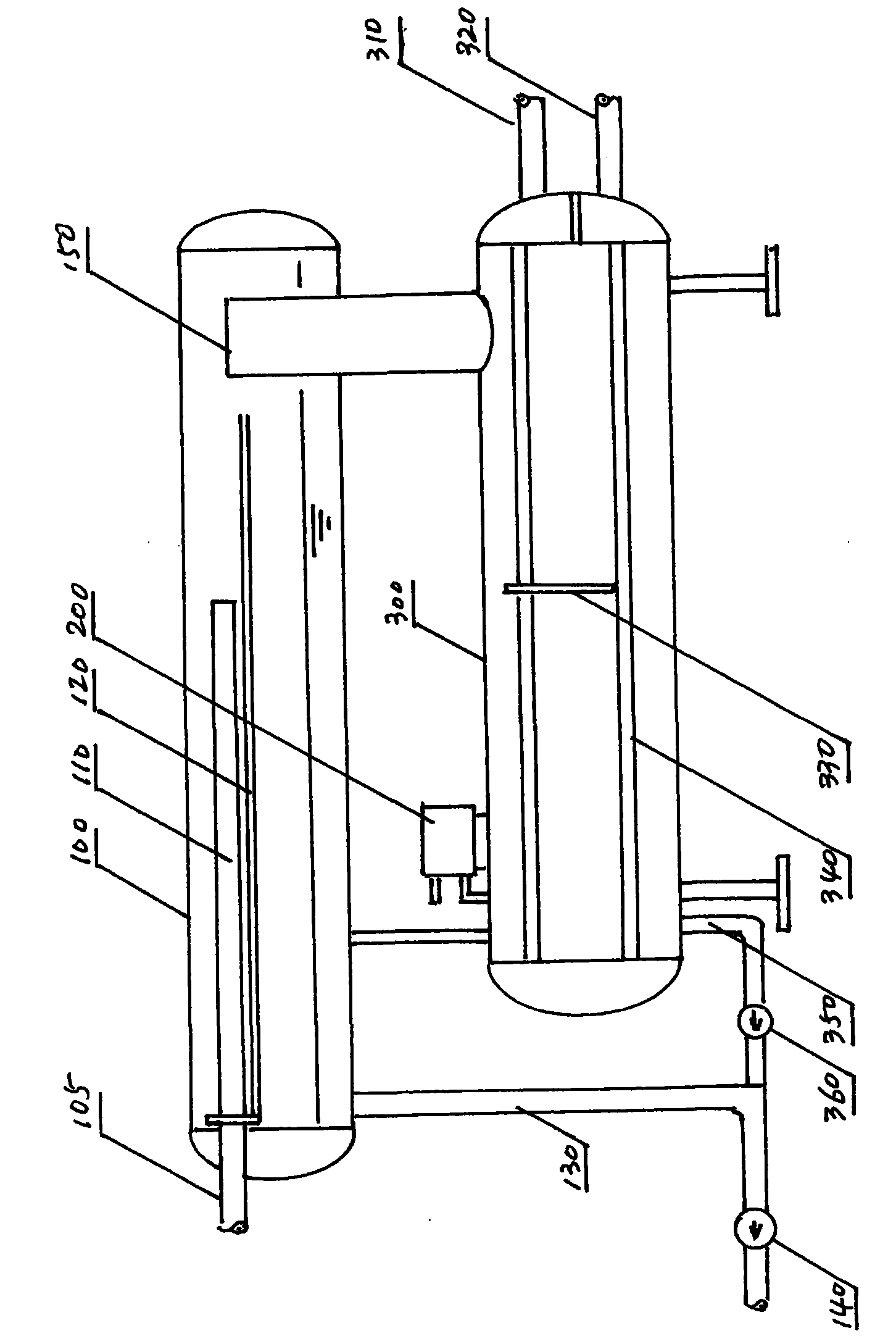

[0030] figure 1 The overall structure diagram of the embodiment of the low-level direct heating machine of the present invention is given.

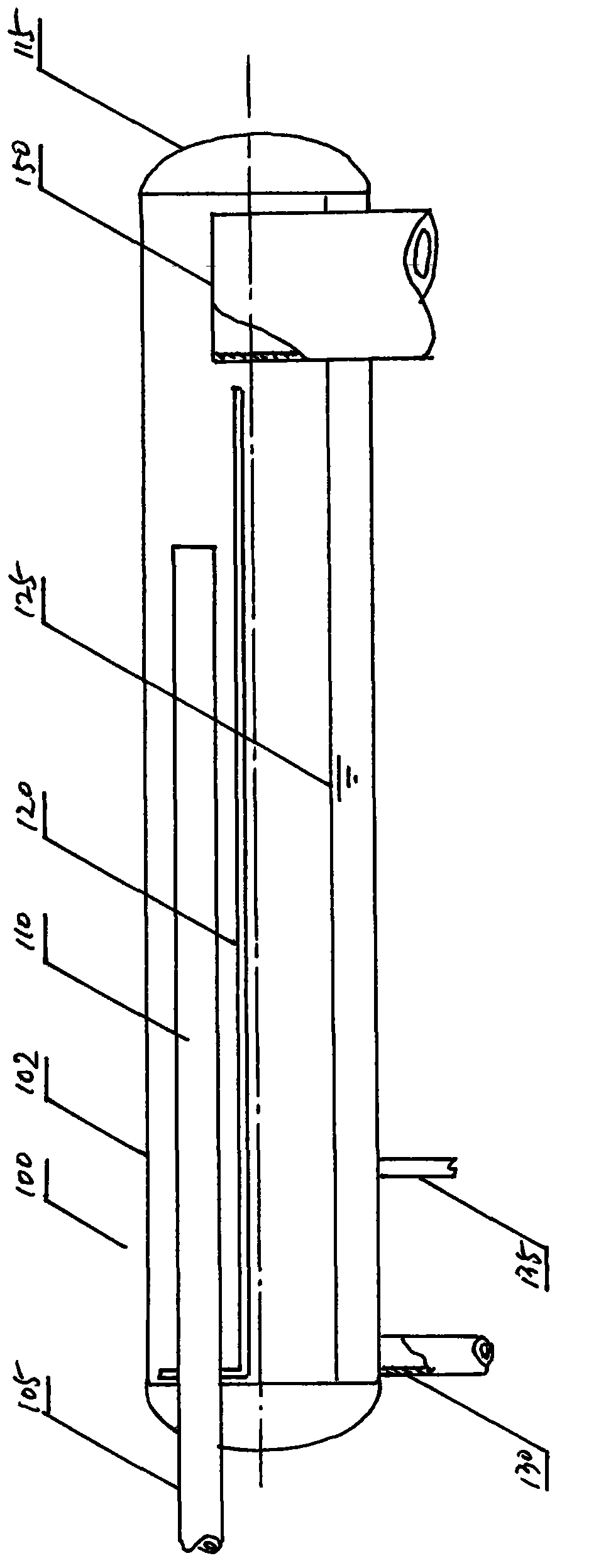

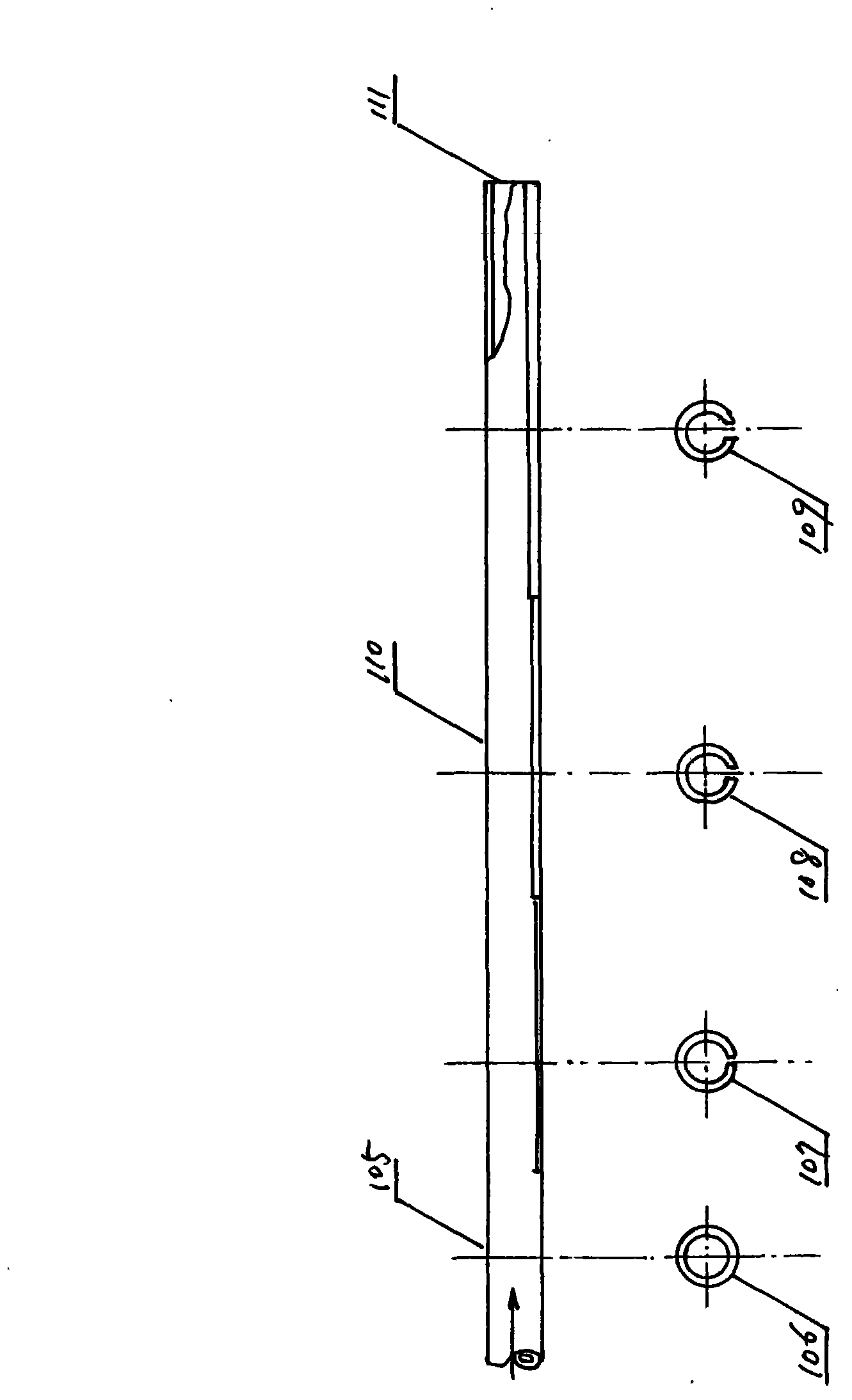

[0031] The overall structure of the embodiment of the low-level direct heat engine of the present invention is divided into upper and lower parts in appearance: the upper part is a horizontal evaporator 100, the lower part is a horizontal condenser 300 and a vacuum pump 200, and there is a steam channel 150 in the middle.

[0032] The medium and high temperature wastewater enters the evaporator 100 through the water inlet pipe 105, and the pressure in the evaporator 100 is lower than the saturation pressure corresponding to the temperature of the inlet medium and high temperature wastewater. Therefore, after entering the evaporator 100, the medium and high temperature wastewater is partially evaporated im...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com