Plate and tube type heat exchanger

A tube heat exchanger, heat exchanger technology, applied in the direction of heat exchange equipment, heat exchanger type, indirect heat exchanger, etc., can solve the problem of heat exchange efficiency reduction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

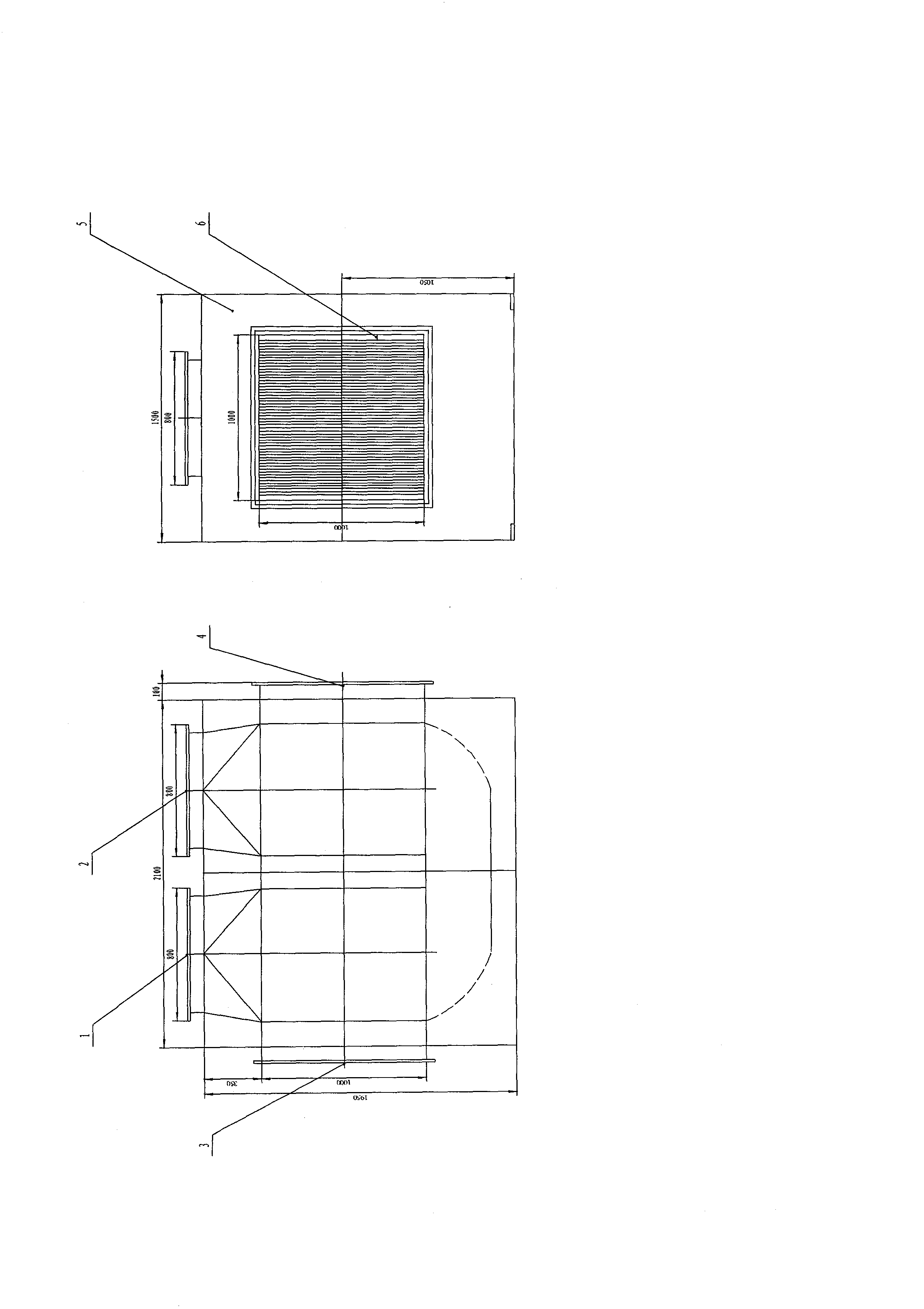

Embodiment approach 1

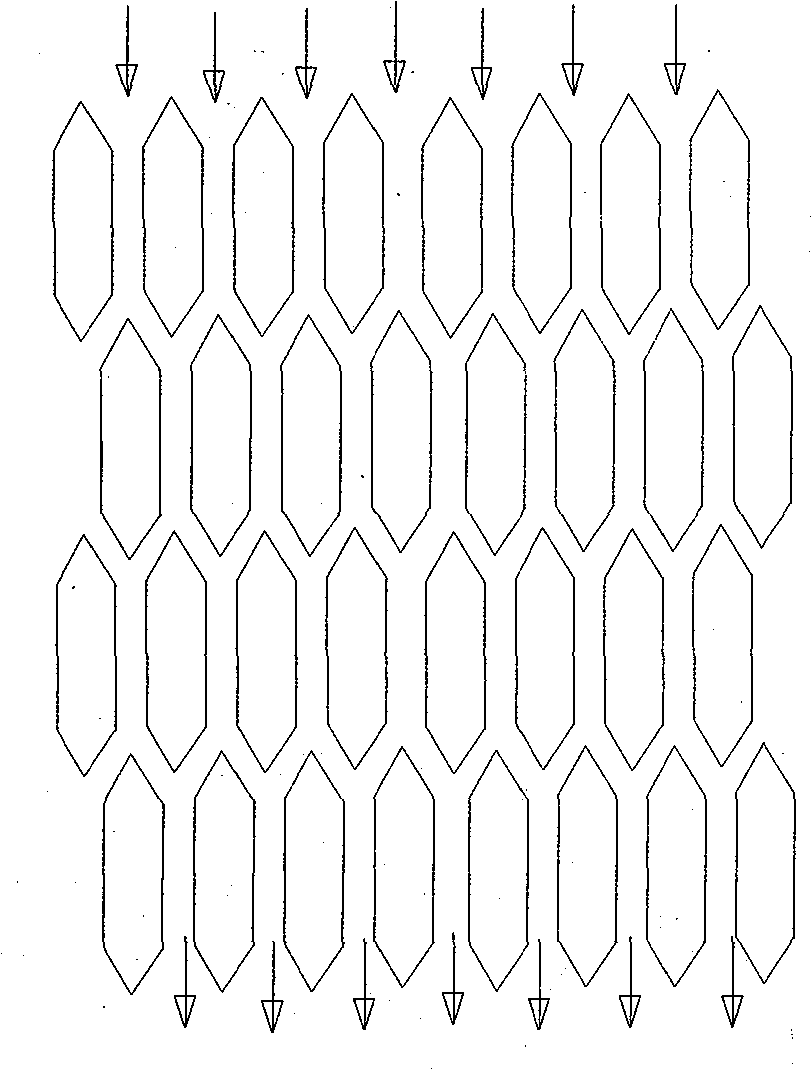

[0015] Embodiment 1: The high-temperature gas enters the heat exchanger through 3 and is discharged through 4; the low-temperature gas to be heated enters from the inlet 2 and is discharged from the outlet 1. At the bottom of 1 and 2, there is an arc-shaped transition plate, so that the gas passes through When 1 flows to 2, the wind resistance is small. The low-temperature gas flows in a sealed tube with a hexagonal structure, two ends forming a triangle, and an angle of 60 degrees. It is sealed with the vertically flowing high-temperature gas and will not cross each other. The positions of the front and rear rows of sealing tubes are mutually staggered, and the rear triangle is just in the 60 ° angle formed by the front two 60 degree angle triangles. Many rows are arranged in this way to form the section of the air inlet direction of the present invention.

[0016] This device has been used in the organic waste gas treatment device of Hangzhou Aishide Environmental Protection ...

Embodiment approach 2

[0018] Embodiment 2: On the basis of Embodiment 1, the air inlet 2 enters, and the 2 cycles before and after exiting from the outlet 1 are changed to 3, 4, and 5 cycles, so that the heat exchange efficiency is higher; when the wind direction changes, There are arc transition plates to reduce wind resistance. However, the more times the wind changes direction, the more wind resistance will increase.

Embodiment approach 3

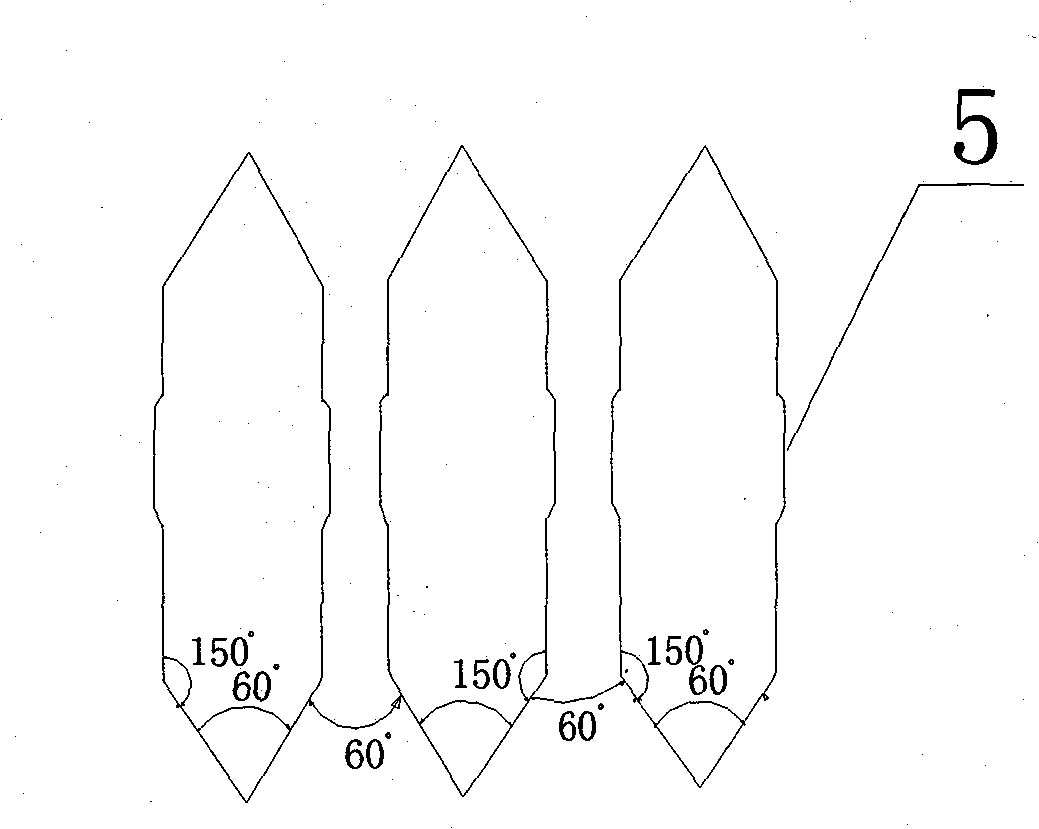

[0019] Embodiment 3: The plate surface is pressurized with lentil-shaped pattern 5, which not only has the effect of strengthening the plate surface, but also can be used as a wind diversion and diversion function. The cross-sectional view is as follows image 3 As shown, the lentil-shaped pattern is as Figure 4 shown.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com