Firecracker production all-in-one machine

An all-in-one machine and firecracker technology, which is applied in pyrotechnics, offensive equipment, weapon types, etc., can solve the problems of incomplete arrangement of firecrackers, uneven charge, weak working stability, etc., and achieve orderly transportation of paper tubes Reliable, reduce the cost of firecracker processing and improve the quality of firecracker processing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

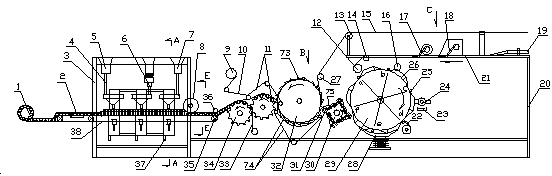

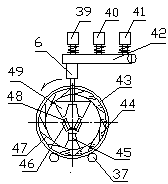

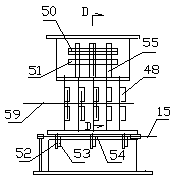

[0016] exist Figure 1-Figure 8Among them, the firecracker production all-in-one machine includes a reel mechanism, an insertion mechanism, a whip and conveying mechanism, a charging and recovery mechanism, and a packaging mechanism; the reel mechanism includes a reel frame 20, a roller 29, and a roller 25 , tile 26, ball 67, shuttle 72, shuttle 60, paper cutting wheel 24, steering wheel Ⅰ12, press plate Ⅰ17, press plate Ⅱ18, water tank 23, tape wheel 16, forming springboard 28, folding plate 22 and outer cylinder 58. Six tiles 26 are evenly spaced in the middle of the outer circle of the roller 29. The direction of rotation of the tiles is the same as that of the rollers. The rotating speed is 1 / 2 of the rollers and rotates synchronously with the rollers. There are six pairs of rollers 25 evenly spaced on the rollers between the tiles, the tiles arranged on the rollers can also be four or eight, and the rollers can be four or eight pairs accordingly One end of the roller pas...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com