Method for ionization chamber X and gamma energy response compensation through nylon material

A technology of energy response and ionization chamber, which is applied in electrostatic dosimeters, circuits, discharge tubes, etc., and can solve problems such as the unsatisfactory tinning compensation effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

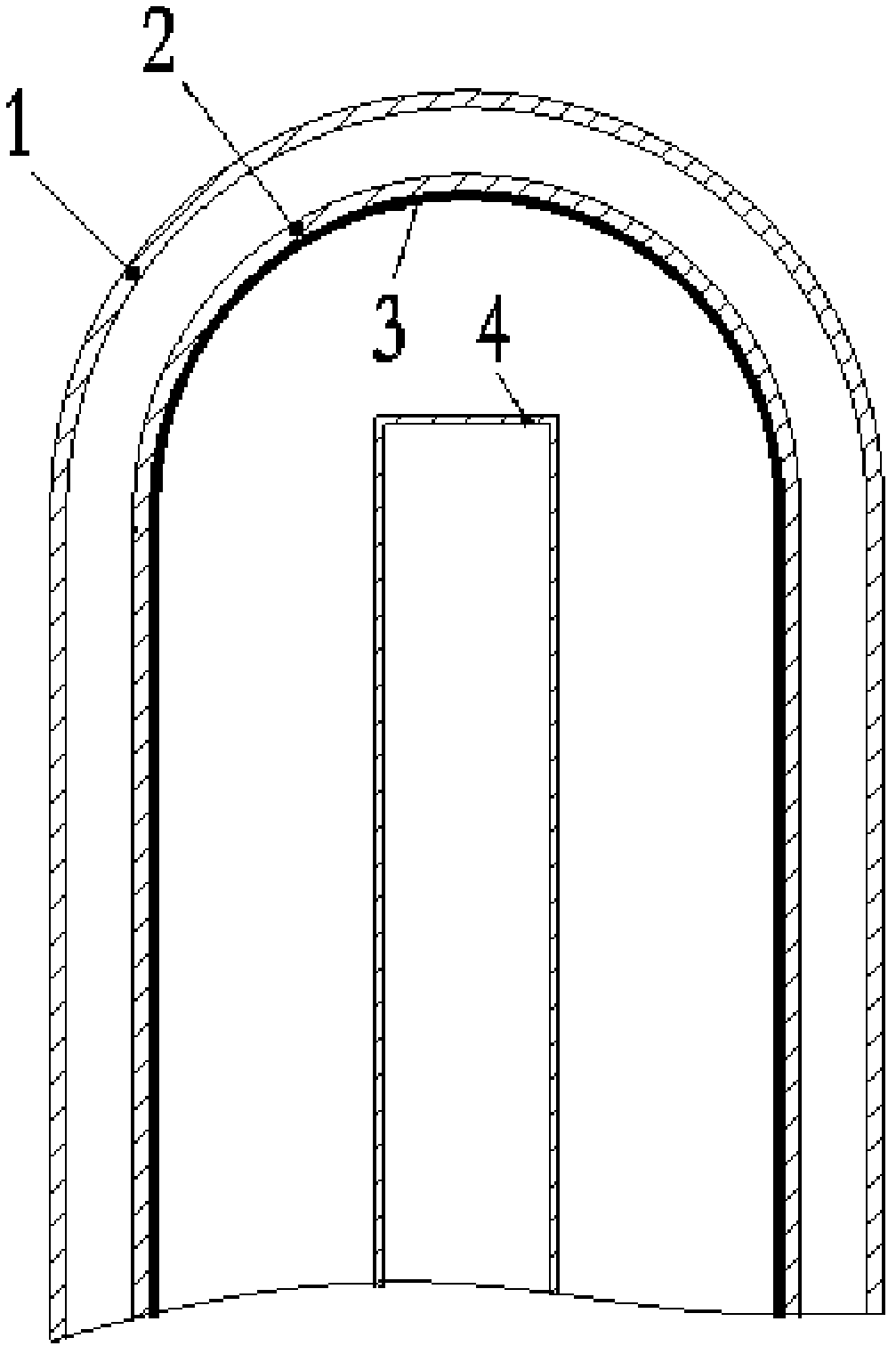

[0011] The present invention will be described in detail below in conjunction with the accompanying drawings and implementation process.

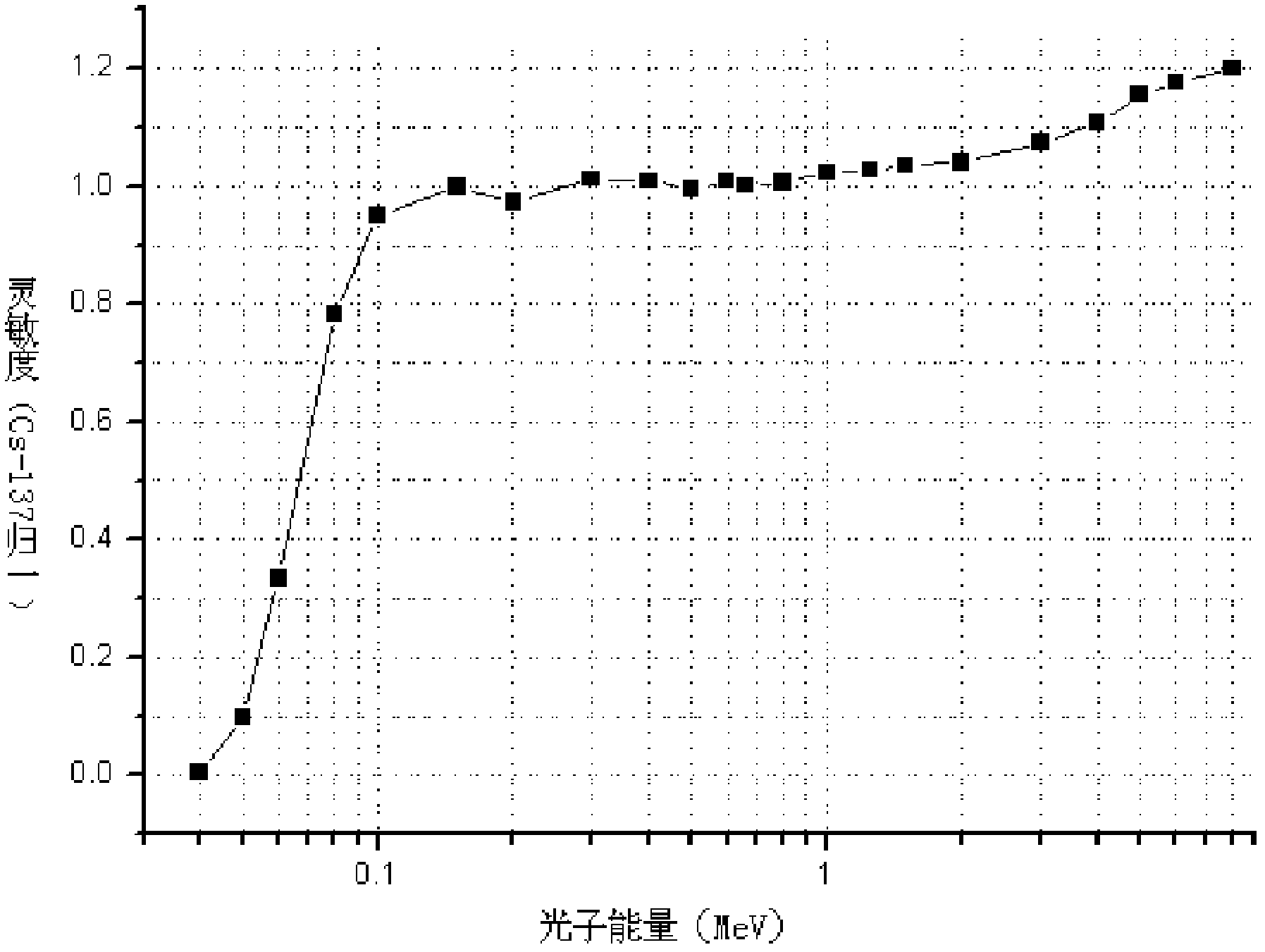

[0012] The present invention uses carbon fiber reinforced nylon material to flatten the response of the steel ionization chamber to X and γ radiation in the energy range of 0.08-7.0 MeV, so that it can 137 Within ±30% of Cs response. Since the average atomic number of nylon is smaller than that of iron, when the nylon material is placed on the inner surface of the stainless steel chamber wall, the over-response problem of the ionization chamber in the energy range of 100-200keV can be better optimized.

[0013] The response of the working gas in the sensitive volume of the ionization chamber to X and γ-rays mainly comes from the contribution of secondary electrons generated by the interaction between the ray and the chamber wall material. While the chamber wall contributes to the response, it also attenuates X and γ-rays. The attenuation ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com