Separation process

A one-part, caustic lye technology, applied in the new separation field, which can solve the problem of long residence time affecting the economics of caustic lye treatment methods

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

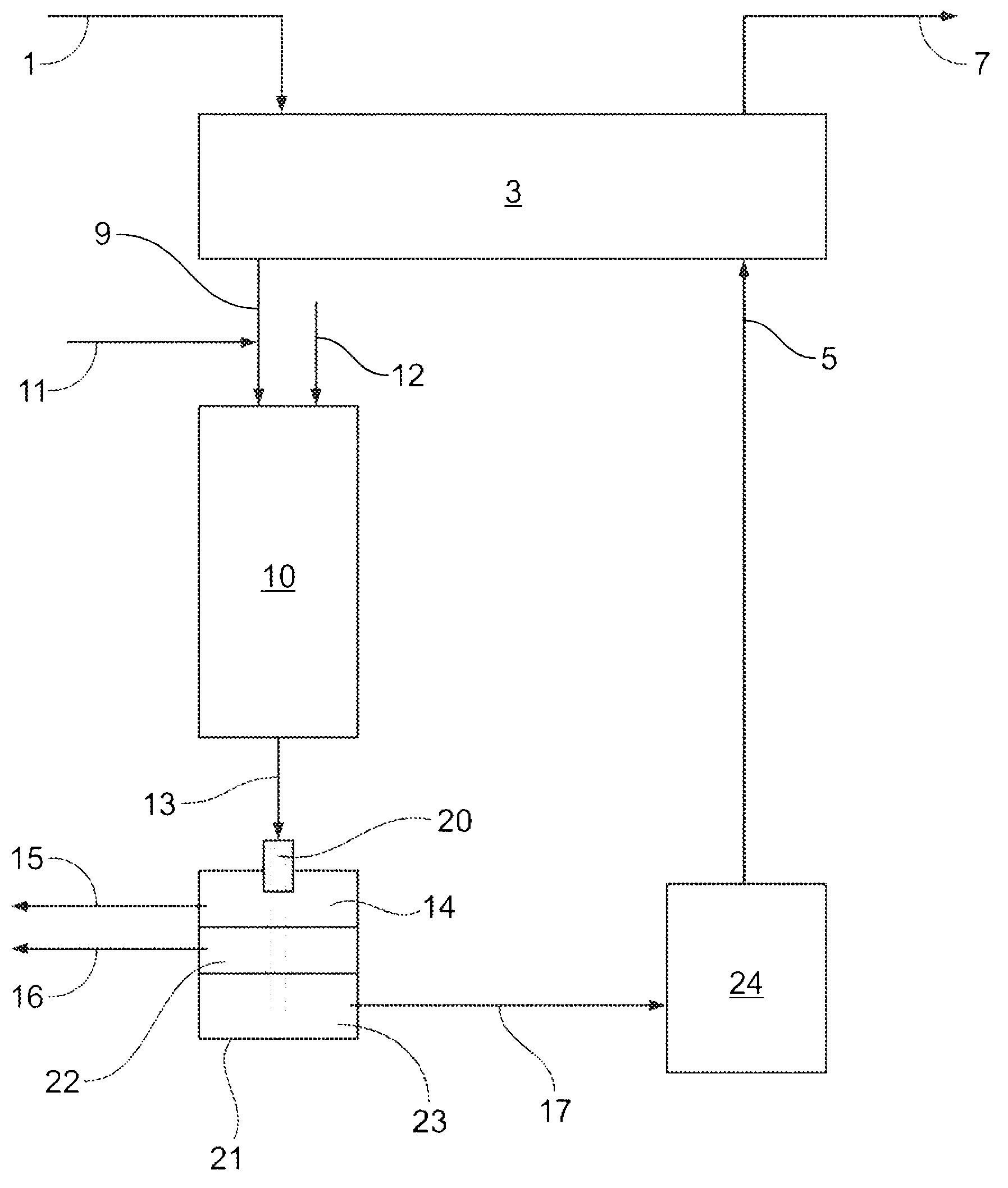

Method used

Image

Examples

Embodiment

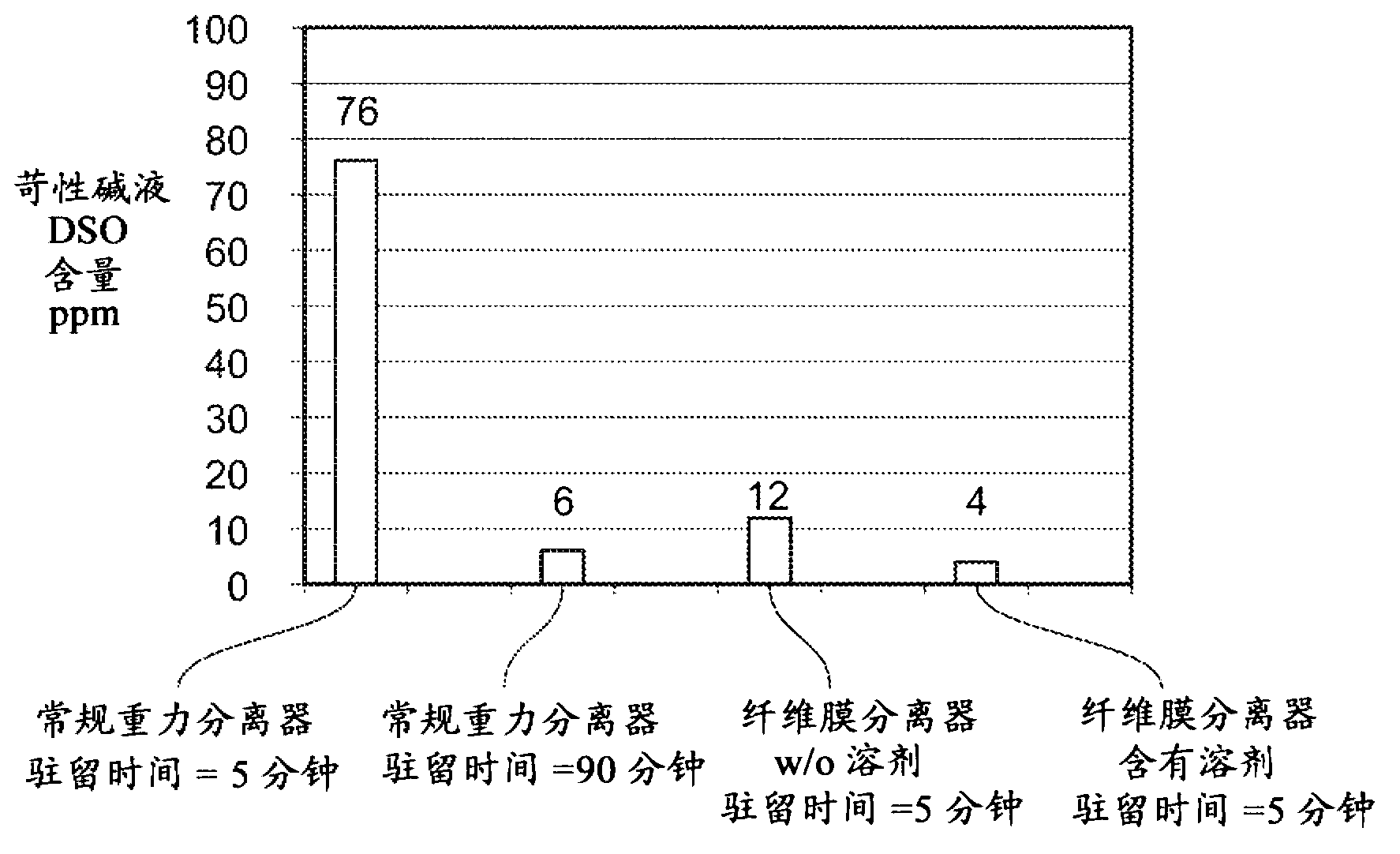

[0036] To illustrate the surprising and unexpected performance of the present invention, laboratory tests were performed to compare a conventional gravity settler (CGS) and the high surface area fiber separator of the present invention. A rich caustic solution of ethanethiol containing about 7000 ppm sulfur was oxidized using a 1-inch diameter oxidizer loaded with ARI-120L solid catalyst at a temperature of about 125°F, 4.0 LHSV and 25 psig back pressure, to 99+% conversion level. Air is injected at about 300ml / min. In a separate test, kerosene was injected into the oxidizer at a rate of about 1.5 ml / min.

[0037] The effluent from the oxidizer containing about 7000 ppm DSO sulfur as diethyl disulfide was first fed to a 3-inch diameter CGS and gravity settled. After 5 and 90 minutes of residence time, the DSO levels in the caustic dropped to about 76 and 6 ppm, respectively ( figure 2 ).

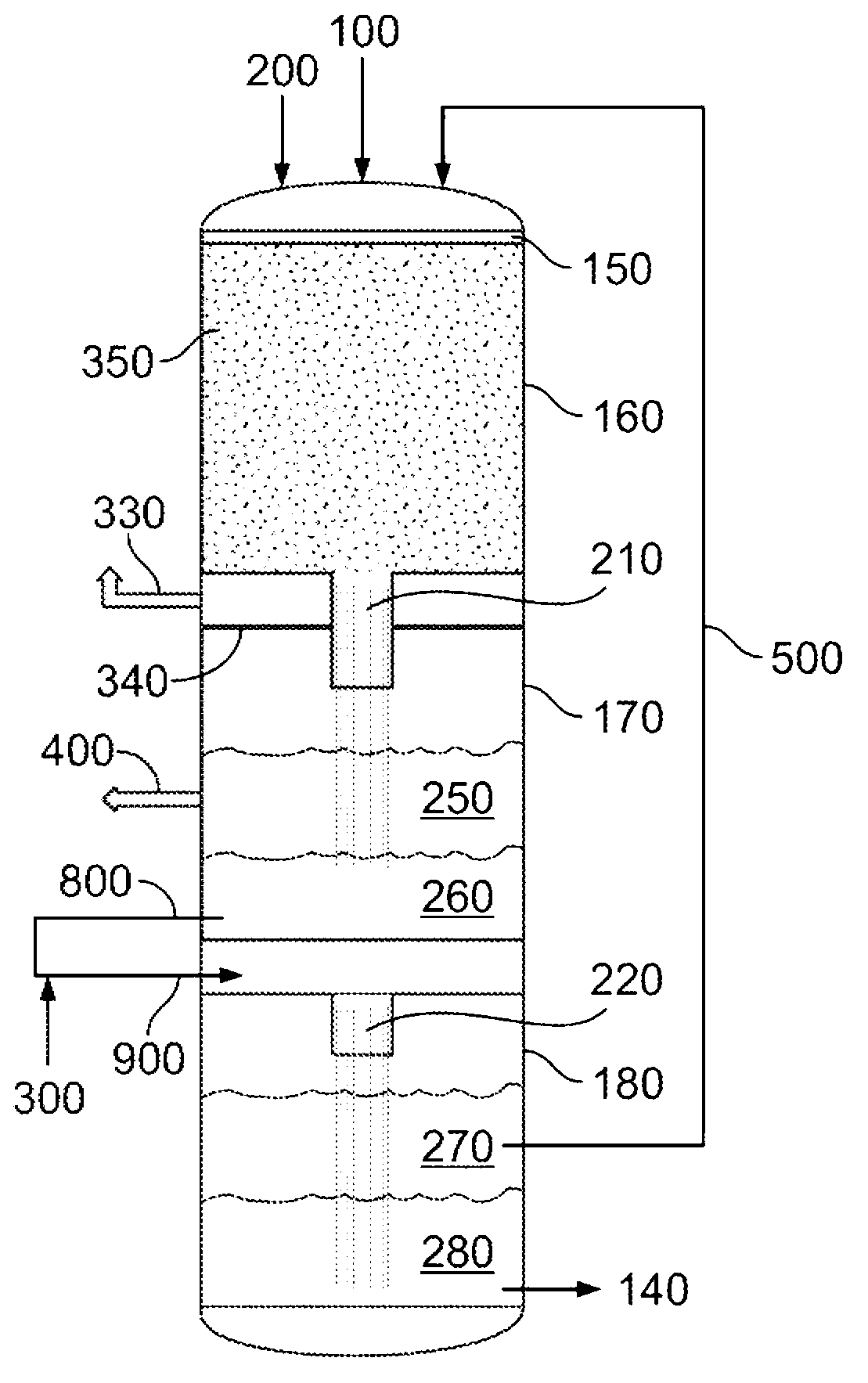

[0038] Then use FIBER The separator replaces the CGS, and the fibers provide an e...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com