Combined and horizontal wet type electric dust precipitator

A wet electrostatic precipitator and horizontal technology, which is applied in the field of compound horizontal wet electrostatic precipitator, can solve the problems of small renovation space, large amount of flue gas in coal-fired power plants, and large floor space, so as to improve the removal efficiency, The effect of reducing chimney corrosion and increasing dust collection area

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0037] The present invention will be further described in detail below in conjunction with the accompanying drawings and embodiments.

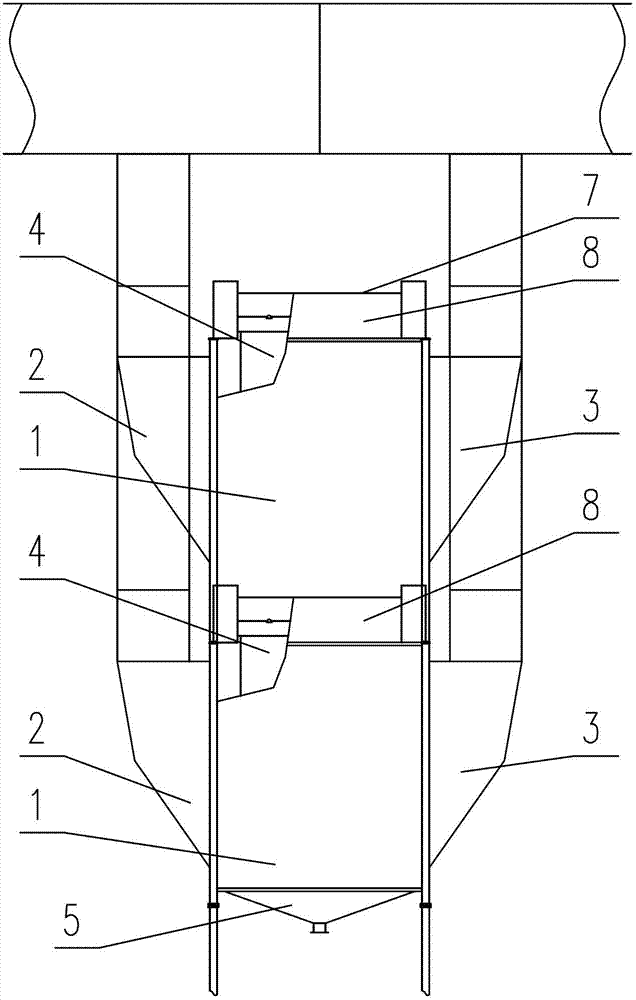

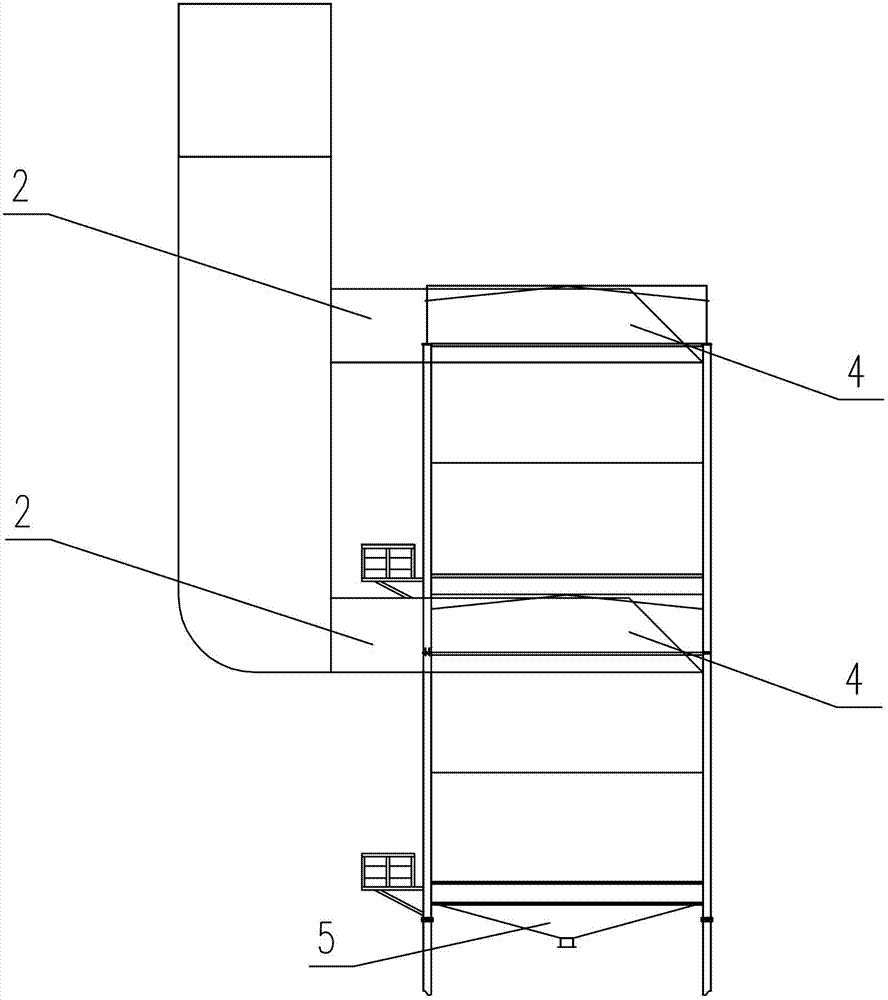

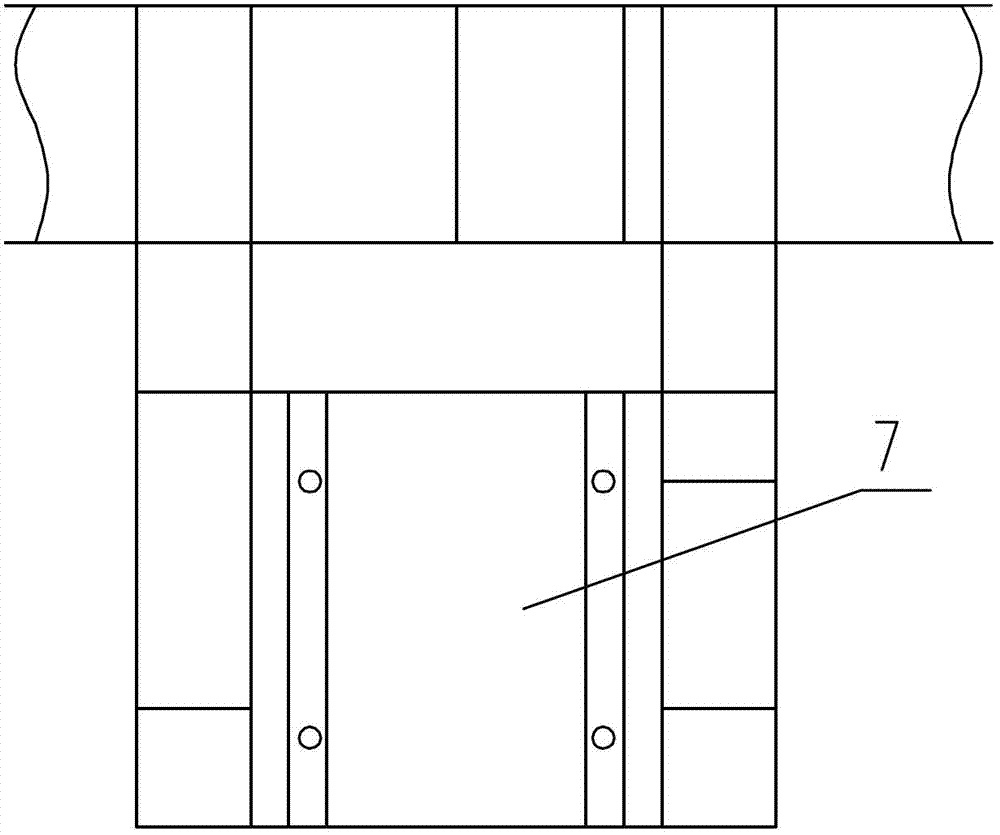

[0038] Embodiments of the present invention provide a compound horizontal wet electrostatic precipitator, such as Figure 1a Figure 1b Figure 1c As shown, although the illustration shows a two-story structure, the three-layer or multi-layer structure only needs to be stacked upwards to turn the top layer into a mezzanine. Through the duplex structure arrangement, the purpose of effectively achieving the purpose of small footprint and doubled total dust collection area .

[0039] A compound horizontal wet electrostatic precipitator, comprising a housing 1, an inlet speaker 2, an outlet speaker 3, a dust removal unit 4, and an ash hopper 5. The dust removal unit 4 includes an anode system, a cathode system, and a spray cleaning system. The above-mentioned dust removal unit 4 is a multi-layer structure with two or more stacked vertically. Th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com