Tool and method for assembling anti-rolling torsion bars with various sizes

An anti-rolling torsion bar and assembly tooling technology, which is applied in assembly machines, manufacturing tools, workpiece clamping devices, etc., can solve problems such as troublesome assembly, and achieve the effects of convenient operation, low cost and high assembly accuracy.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

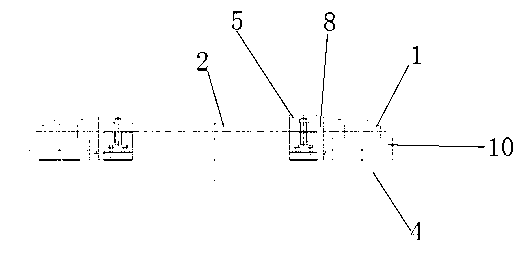

[0035] The technical solution of the present invention will be described in further detail below in conjunction with the accompanying drawings and embodiments.

[0036] As shown in the figure, an assembly tool for anti-roll torsion bars of various specifications includes a bracket 3, a workbench 4 set on the support 3, and a sliding or fixed workbench set on the workbench 4. The support base 5 in the state, the support base 5 includes a fixing device 6 and a base 7 for fixing the torsion bar shaft, a positioning baffle 8 arranged on the side of the support base 5, and the positioning baffle 8 is used to set the torsion arm 1 is separated from the base 7 of the support base by a certain distance, and has been adapted to interfere with the base 7 when some special-shaped torsion arms are assembled. It also includes an arc-shaped gasket 9 and a height positioning block 10 for positioning the relative height deviation of the torsion arm. Shape washer 9 cooperates with fixing devic...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap