Trailer driving device for four-wheel drive tractor

A driving device and tractor technology, applied in the control device, vehicle parts, transportation and packaging, etc., can solve the problems of agricultural trailers stuck in mud pits or silt, affecting agricultural production and transportation, and insufficient traction power of four-wheel drive tractors, etc. The operation efficiency of the whole vehicle, the structure is simple, and the effect of anti-slip or side-slip is not easy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

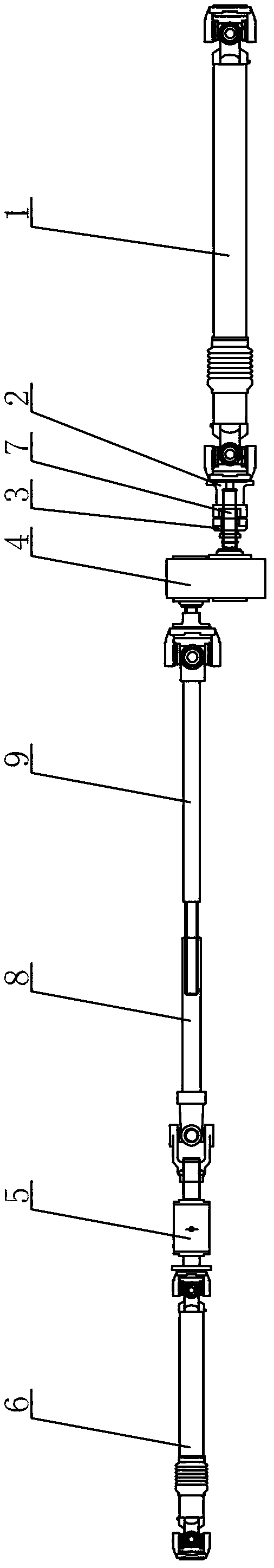

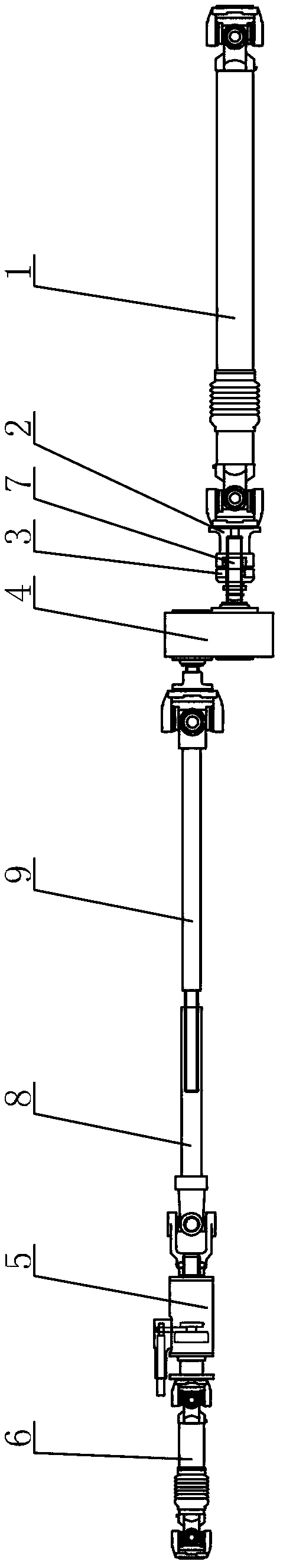

[0007] Embodiment 1: Combining Figure 1 to Figure 5 Illustrating this embodiment, a trailer drive device for a four-wheel drive tractor described in this embodiment includes a trailer drive shaft 1, a first three-tooth connecting gear 2, a second three-tooth connecting gear 3, a gearbox 4, an intermediate transmission shaft assembly, The clutch transmission mechanism 5, the power shaft 6 and the gearbox connecting shaft 7, one end of the trailer drive shaft 1 is connected with the trailer rotating shaft through a universal joint, and the other end of the trailer drive shaft 1 is connected with the first three-tooth connecting gear 2 through a universal joint , one end of the gearbox connecting shaft 7 is inserted into the first three-tooth connecting gear 2, the other end of the gearbox connecting shaft 7 is connected to the gearbox 4, and the second three-tooth connecting gear 3 is sleeved on the gearbox connecting shaft 7, And the second three-tooth connecting gear 3 can me...

specific Embodiment approach 2

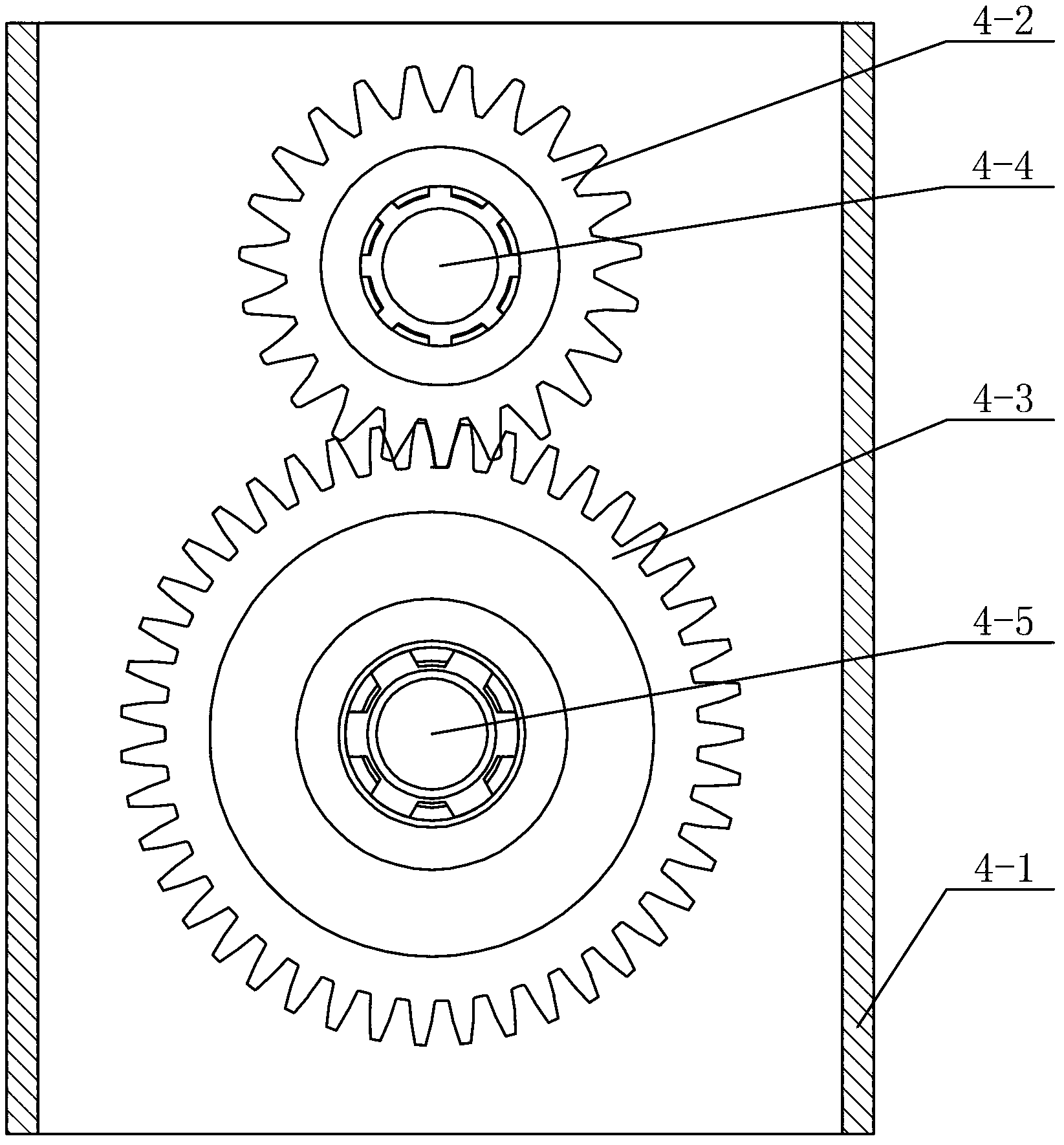

[0008] Specific implementation mode 2: Combining image 3 Illustrating this embodiment, the gearbox 4 of a trailer drive device for a four-wheel drive tractor described in this embodiment includes a gearbox body 4-1, a driving gear 4-2, a driven gear 4-3, a driving shaft 4-4, and a driven gear 4-4. The shaft 4-5, the driving gear 4-2 and the driven gear 4-3 are arranged in the gearbox body 4-1 in order from top to bottom, the driving gear 4-2 is sleeved on the driving shaft 4-4, and the driven gear 4-3 It is sleeved on the passive shaft 4-5, one end of the passive shaft 4-5 is connected with the other end of the gearbox connecting shaft 7, and one end of the driving gear 4-4 is connected with one end of the intermediate transmission shaft assembly through a universal joint.

[0009] The technical effect of this embodiment is that the gearbox 4 can change the transmission ratio, expand the variation range of the torque and rotational speed of the driving wheel, so as to adapt t...

specific Embodiment approach 3

[0011] Specific implementation three: combination figure 1 and Figure 4 Illustrating this embodiment, the clutch transmission mechanism 5 of a trailer drive device for a four-wheel drive tractor described in this embodiment includes an outer clutch shaft 5-1, an outer clutch housing 5-2, an outer clutch connection flange 5-3 and two There are two outer clutch bearings 5-4, and two ends of the outer clutch housing 5-2 are respectively provided with an outer clutch bearing 5-4. Both ends of the outer clutch shaft 5-2 are respectively inserted into an outer clutch bearing 5-4. 4. One end of the inner and outer clutch shaft 5-1 is connected with the other end of the intermediate transmission shaft assembly, and the other end of the outer clutch shaft 5-1 is connected with the outer clutch flange 5-3.

[0012] Other components and connection relationships are the same as in the first embodiment.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com