Suspension internal gear structure for reducing noise of high-speed motor of electric bicycle

A technology of electric bicycles and high-speed motors, which is applied to vehicle gearboxes, vehicle components, wheel transmissions, etc., to achieve the effects of reducing noise, reducing current impact, and buffering shock waves

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

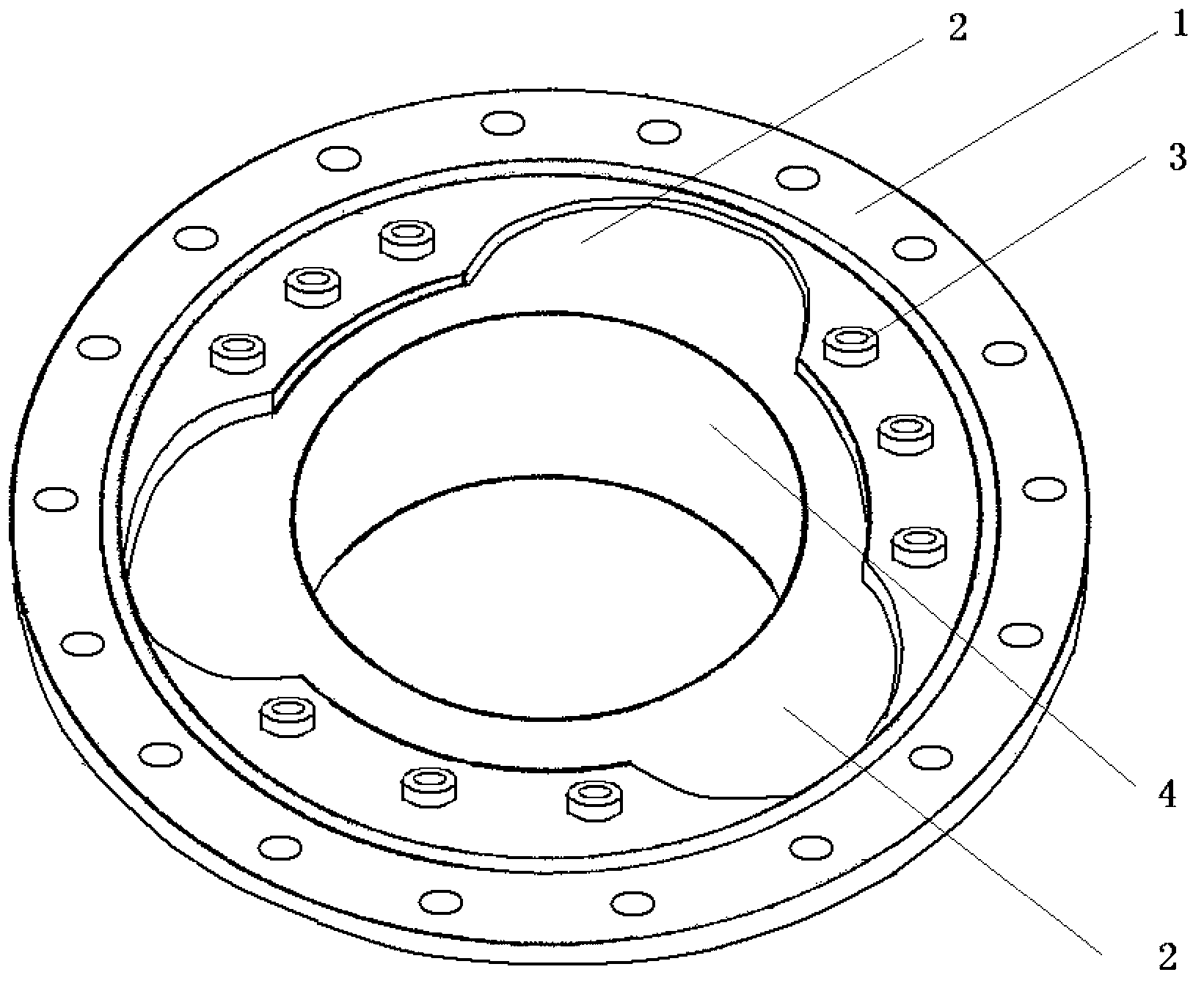

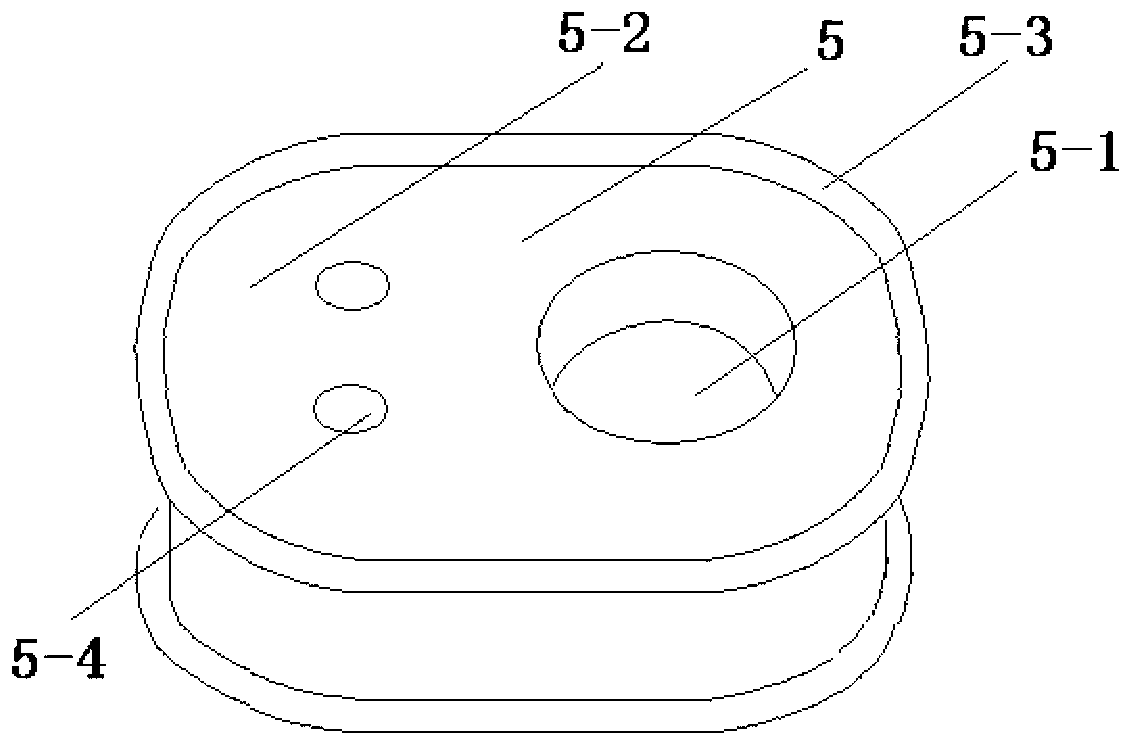

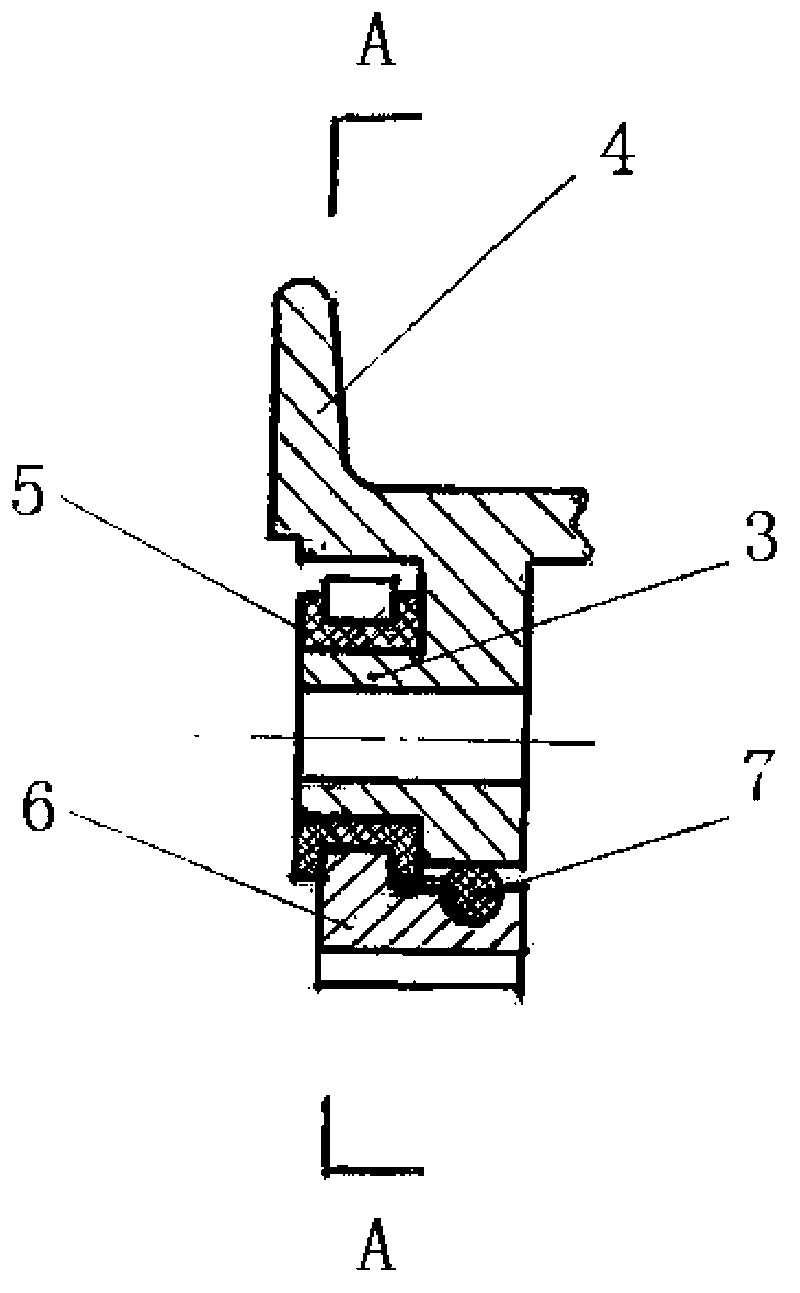

[0029] Embodiment 1, a low-noise transmission mechanism for a high-speed motor of an electric bicycle. refer to figure 1 , figure 2 , image 3 : the transmission mechanism is composed of a sun gear, a planet carrier and an internal gear meshing with each other to form a planetary gear two-stage reduction mechanism, wherein the sun gear shaft is coupled with the high-speed motor of the electric bicycle; the coupling between the internal gear 6 and the high-speed motor shell 4 of the electric bicycle adopts elastic coupling, and the The elastic coupling structure is as follows: on the high-speed motor housing 4 of the electric bicycle, there is a boss 3 for transmitting torque, and an elastic body 5 (also called a buffer compensation body or an elastic damper) is installed on each boss for transmitting torque. shock damping bracket); the elastic body 5 is composed of a fitting hole 5-1 and an elastic body wing edge 5-3; the fitting hole 5-1 of the elastic body is set on the b...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com