Lifting wheel body of bottle washer with double bottle feeding tracks

A bottle washing machine and lifting wheel technology, which is applied in the field of bottle washing machines, can solve the problems that the lifting of bottles cannot adapt to large-scale production, restricts the development of the pharmaceutical industry, and unreasonable design

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0006] Below in conjunction with accompanying drawing, the present invention is further described:

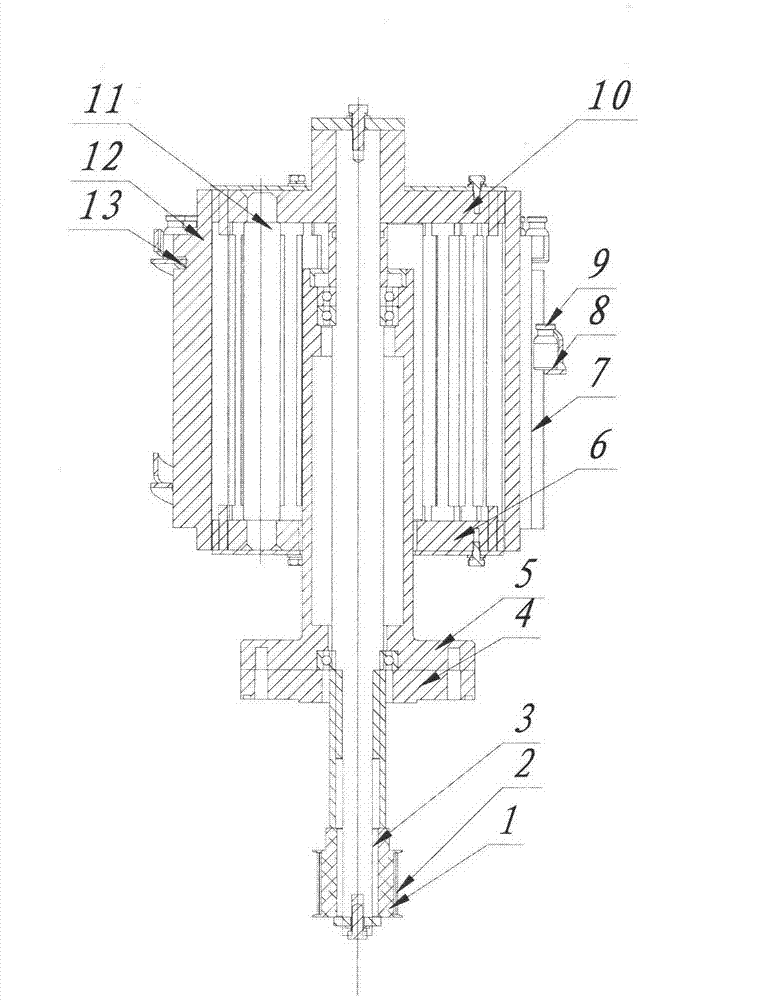

[0007] See attached figure 1 , fixed on the frame through the fixed seat 4, the shaft seat 5 is fixed on the fixed seat 4; the rotating shaft 3 is flexibly fixed at the center of the shaft seat 5 through the bearing, the lower end of the rotating shaft 3 is fixed with a synchronous pulley 1, and the synchronous pulley 1 is connected with a synchronous Belt 2; the upper support 10 and the lower support 6 are fixedly connected by the connecting rod 11, and the outer circumference between the upper support 10 and the lower support 6 is evenly fixed with 20 lifting slots 12, and the slots of the lifting slots 12 are respectively inserted Driving lever 7 is arranged, and the lifting groove seat 12 periphery is provided with the lifting helical groove 8 that is fixed on the frame, and lower support 6 is empty sleeve outside axle seat 5, and upper support 10 is fixed on rotating shaft...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com