Auxiliary monitoring system suitable for high-temperature oxide crystal growth

A monitoring system and crystal growth technology, applied in crystal growth, single crystal growth, single crystal growth, etc., can solve the problems of destroying the symmetry of the temperature field, inconvenient observation, sudden changes in the heat insulation environment, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0017] Hereinafter, the present invention will be further described with reference to the accompanying drawings and in combination with the following embodiments. It should be understood that these embodiments and examples are only for illustrating the present invention, and are not intended to limit the present invention.

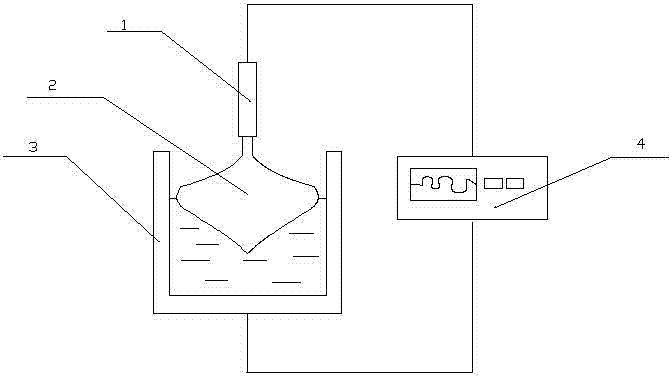

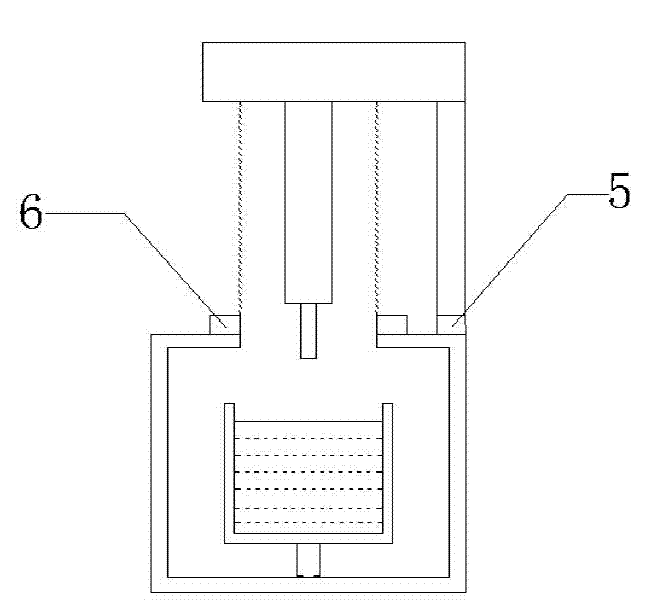

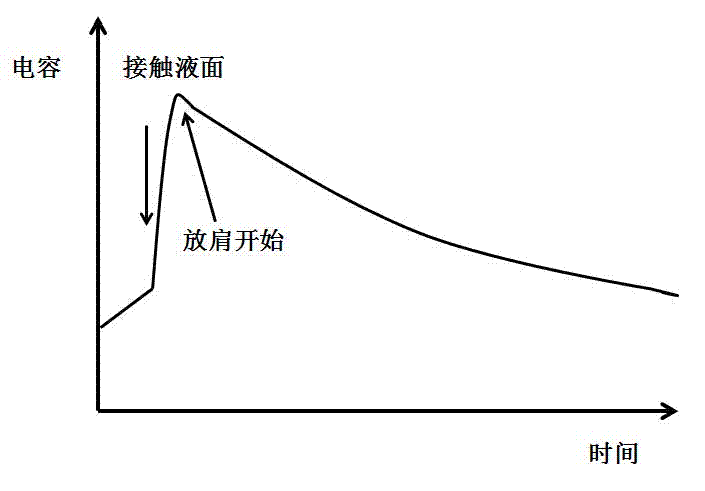

[0018] The technical solution adopted in the present invention is: through a certain design, the seed crystal clamping unit (such as the seed crystal pulling equipment, specifically, such as the seed crystal rod, the seed crystal clamp) and the seed crystal and the growth furnace (including the entire furnace body) and other auxiliary equipment, such as heating equipment), the above part (seed crystal holding unit) and the furnace body form a capacitor. Oxide crystals and melts are used as dielectrics, and their growth process can be seen as a process in which the ratio of crystals to melts is constantly changing. Since the dielectric constants of melts an...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com