Large-area hydraulic fill dredging powder ground base disposed by vibration liquidizing drainage

A technology of vibration liquefaction and drainage method, which is applied in soil protection, infrastructure engineering, construction, etc., and can solve problems such as unsatisfactory

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

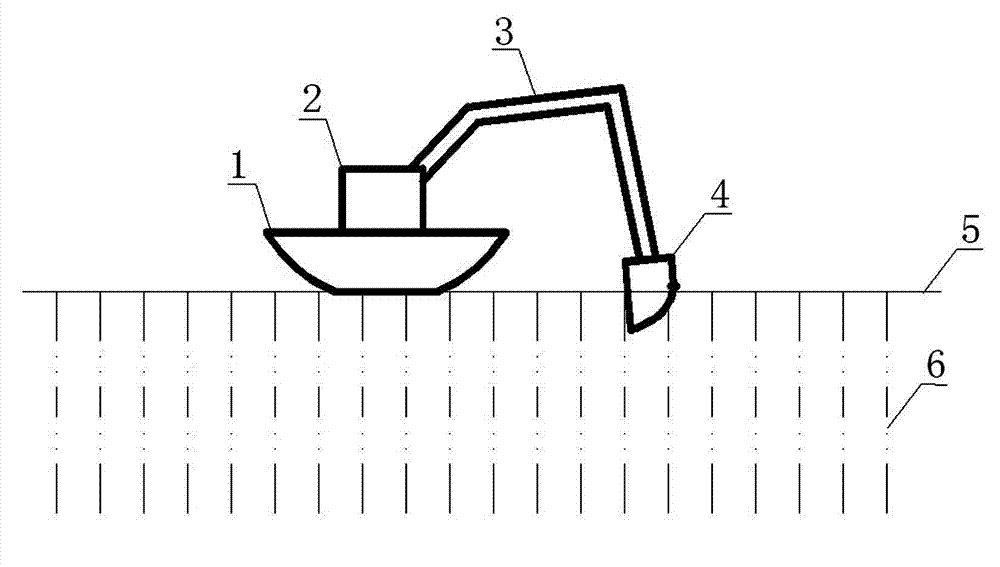

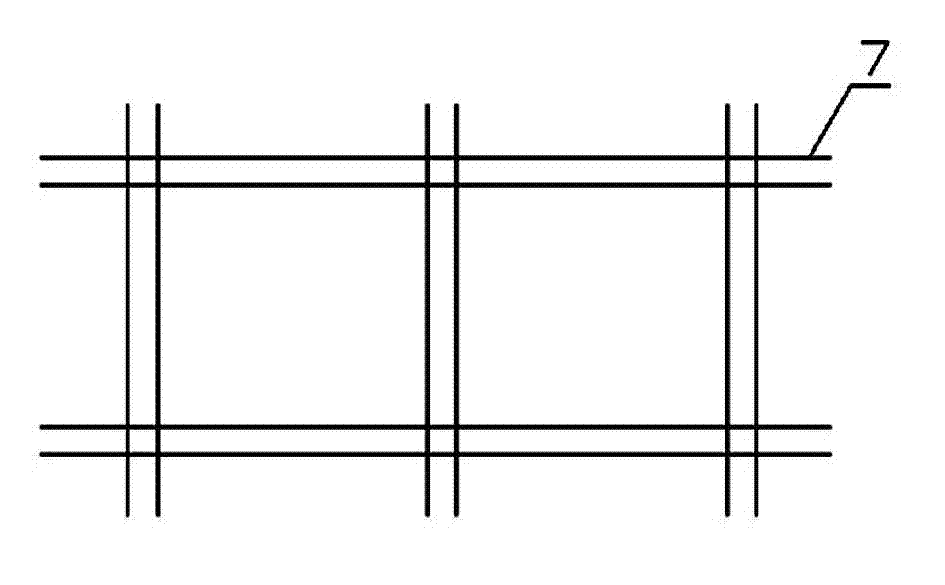

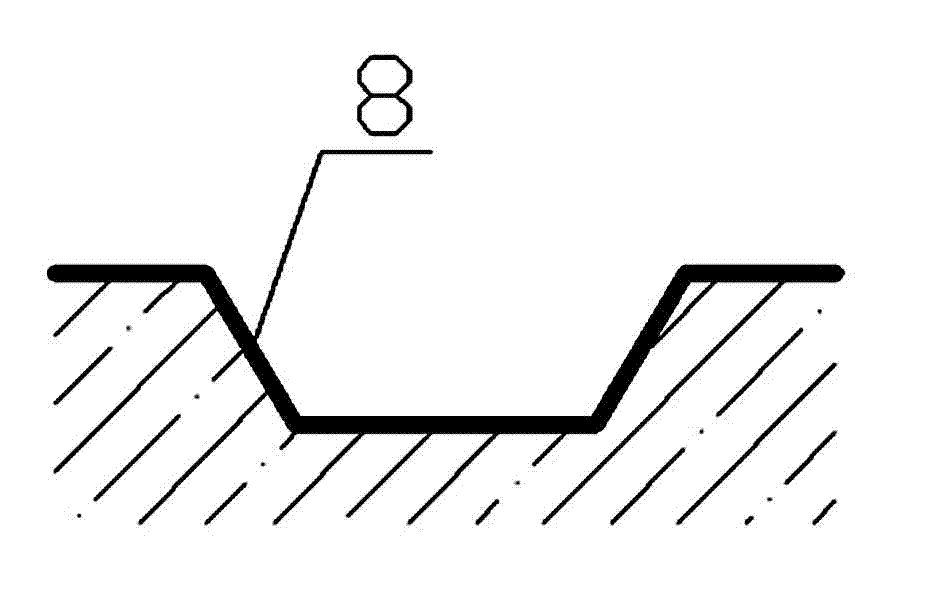

[0009] The present invention utilizes water excavator (see figure 1 ) There are two buoyancy tanks 1 to enable the water excavator to run normally on the surface 5 of saturated dredging silt. Carry out vibration liquefaction and drainage on the dredged powder soil foundation 6. When vibrating, the grab bucket vibrates vertically and downwards, and can also vibrate in the horizontal direction to a distance of 2.0m. Repeated vibrations can fully liquefy the vibrating parts; excavate drainage ditches 7 at intervals of 20m×20m on the site (see figure 2 ) to remove the free water that is vibrated and liquefied by the grab bucket of the water excavator, and the section 8 of the drainage ditch (see image 3 ) with a width of 1.0m and a depth of 0.5m. After the drainage construction is completed, a land excavator will be used to reinforce the local area with poor treatment effect. The above vibration liquefaction drainage method can be repeated 5 to 8 times, and the time interval b...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com