A pile-forming steel pipe for bottom-expanding crushed stone pile and its construction method

A construction method and technology of gravel piles, applied in sheet pile wall, foundation structure engineering, construction, etc., can solve the problems of single and backward method, increase extrusion, etc., achieve smooth and convenient delivery, improve compression modulus and bearing capacity , the effect of compaction is good

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

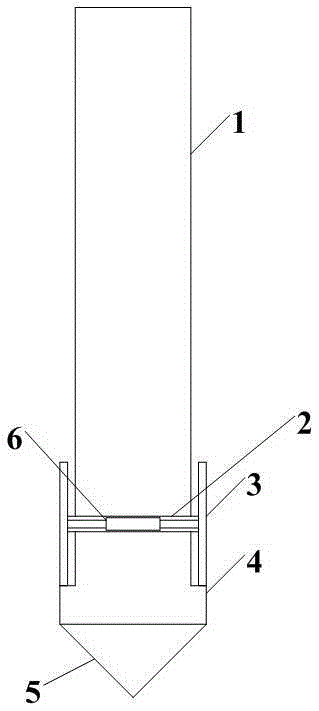

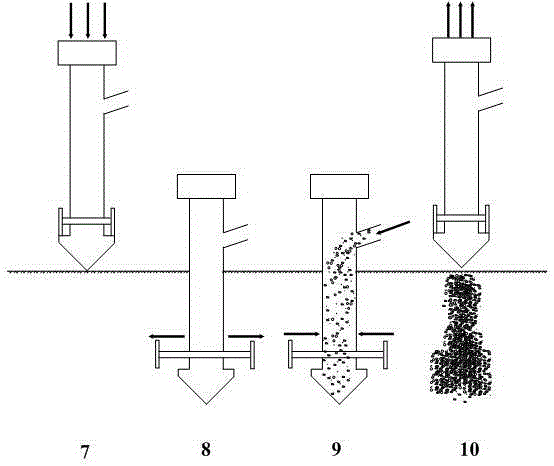

[0035] Bottom-expanding crushed stone pile of the present invention becomes pile steel pipe and construction method thereof such as figure 1 , 2 shown. The enlarged bottom gravel pile strengthens the compaction capacity of the gravel pile on the basis of the gravel pile, improves the bearing capacity of the pile body itself, and the construction process is only slightly more complicated than that of the gravel pile.

[0036]The bottom-expanding crushed stone pile-forming steel pipe of the present invention includes: a straight pipe feeding part (1) on the upper part of the pile pipe and a bottom-expanding part on the lower part, wherein the bottom-expanding part includes an enlarged head type valve pile tip (5), an enlarged bottom The hydraulic propulsion device (6), the fixed shaft (2) of the fixed link on the side wall of the pile pipe, and the pushing steel plate (3), wherein the pushing steel plate (3) can be a semi-cylindrical ring or other shapes, when it is a semi-cir...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com