Circular tube guardrail connecting component and circular tube guardrail

A technology for connecting components and round pipes, applied in building structures, stepped structures, buildings, etc., can solve problems such as poor safety and unsightly appearance of balcony guardrails, improve product competitiveness and customer satisfaction, high safety, Good rigidity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] The specific implementation manner of the present invention will be described below in conjunction with the accompanying drawings.

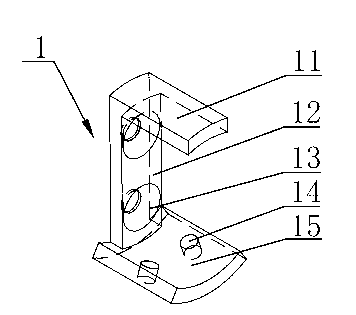

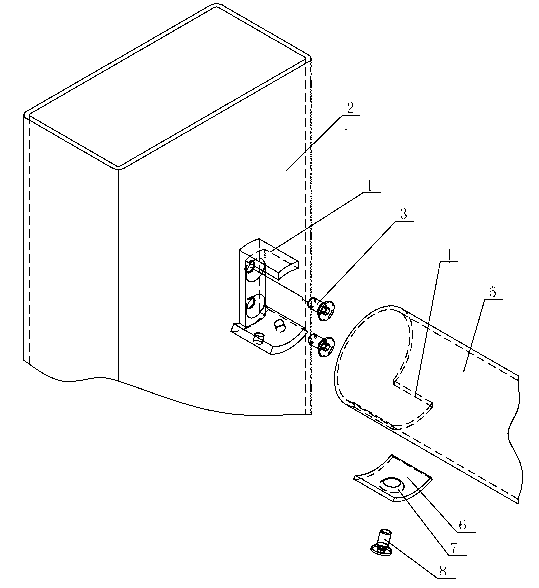

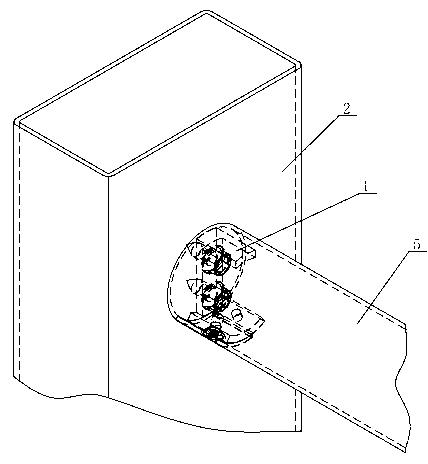

[0019] Such as figure 1 As shown, the round tube guardrail connecting member 1 of the present invention adopts metal die-casting and post-machining molding, and the middle vertical plate 12 connects the upper top arc portion 11 and the lower bottom arc portion 15, and the top arc portion 11 and the bottom arc portion 15 The outer diameter is matched with the inner diameter of the circular pipe 5 as the horizontal bar. Two fixing holes 13 are arranged on the vertical plate 12, and two connecting holes 14 are processed symmetrically on the bottom arc 15 with the neutral plane. The connecting holes 14 The central axis passes through the center of the arc and forms an acute angle with the plumb line, which is 15 degrees in the present embodiment. The function of being provided with two connecting holes 14 is to be compatible with fixing the l...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com