Variable displacement oil pump and engine lubrication system with the oil pump

A technology of displacement machine and oil pump, applied in the direction of engine lubrication, machine/engine, pressure lubrication of lubricating pump, etc., can solve the problems of inconvenient assembly operation, increase engine cost, increase engine fuel consumption, etc., to ensure good performance , to ensure the sealing performance, the effect of less oil pressure loss

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0034] Embodiment 1 A variable displacement oil pump

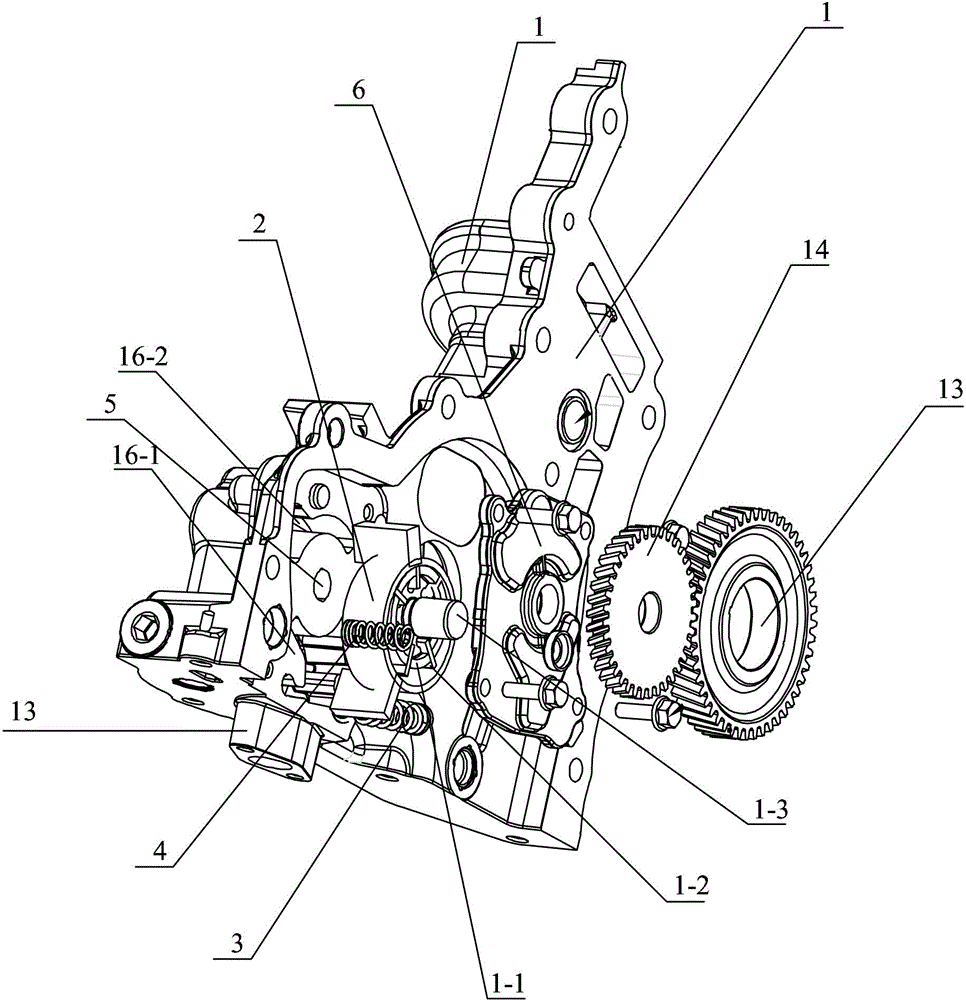

[0035] The structure of a variable displacement oil pump in this embodiment is as follows: figure 1 As shown: the vane sheave 1-1 is included, and the vane sheave 1-1 is provided with a vane 1-2. When working, the vane 1-2 rotates to generate power and then absorbs oil from the oil pan. In order to ensure the safety of the vane sheave 1-1 and the vane 1-2, the vane sheave 1-1 and the vane 1-2 are set in the rotating cavity 2 on the oil pump housing, and the vane center shaft 1-3 is fixed on the oil pump housing. In order to realize the controllability of the engine oil displacement in this embodiment, the rotating chamber 2 is arranged on the oil pump housing through an eccentricity adjustment mechanism, and the rotating chamber 2 can rotate relative to the oil pump housing; the central shaft of the blade 1- 3 is directly fixed on the oil pump housing, and the eccentricity between the rotating chamber 2 and the central...

Embodiment 2

[0039] Embodiment 2 An engine lubrication system with a variable displacement oil pump

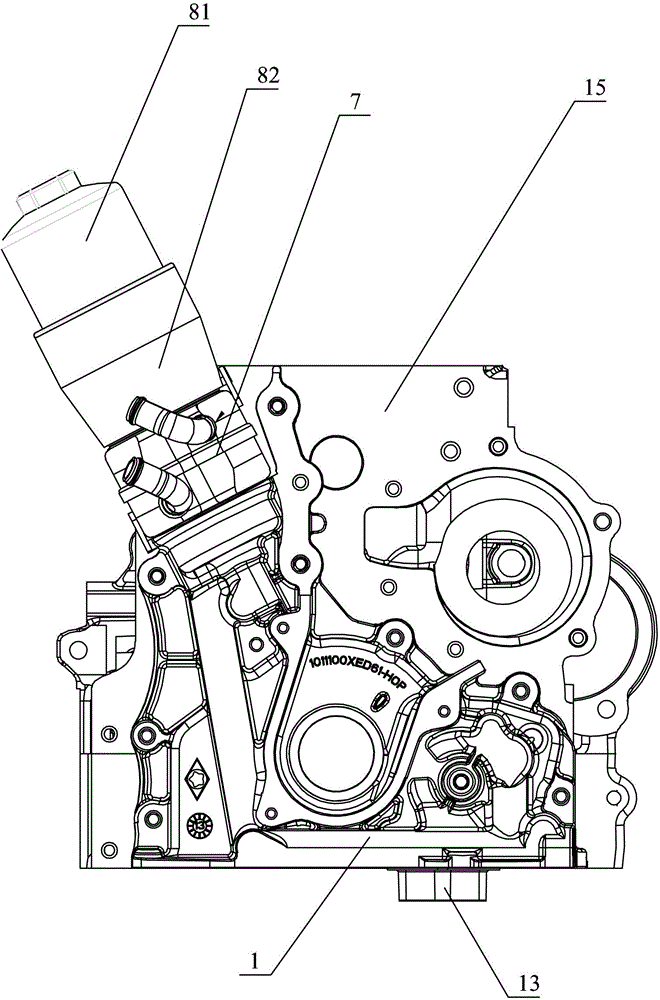

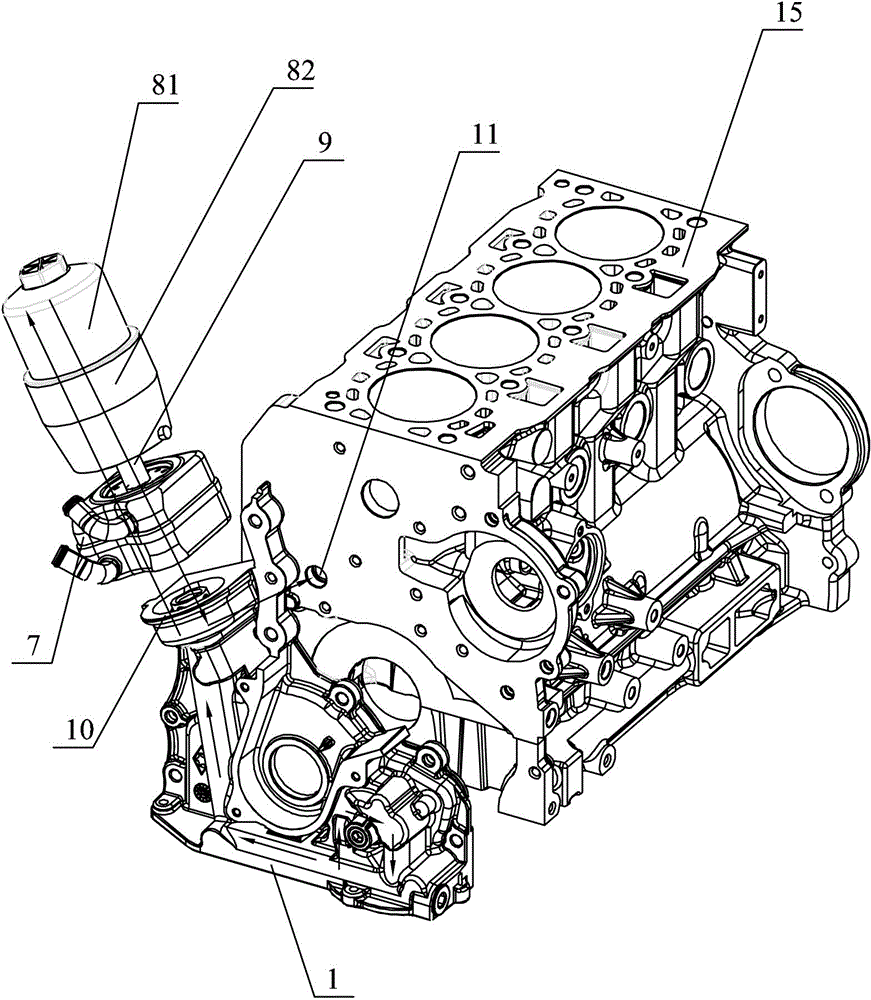

[0040] This embodiment relates to an engine lubrication system with a variable displacement oil pump, the structure of which is as follows figure 2 , image 3 Shown: includes a cooler 7 for cooling the oil, a filter for filtering the oil, and a variable displacement oil pump 1 for pumping oil from the oil pan, where variable The structure of the displacement engine oil pump 1 is exactly the same as that of the embodiment, and will not be repeated here.

[0041] During installation, the variable displacement oil pump 1 is fixed on the cylinder block of the engine 15 through bolts, and the oil inlet flange 13 of the variable displacement oil pump 1 is connected to the oil pan, and the oil outlet is connected to the cooler 7 The oil inlet of the cooler 7 is connected to the oil inlet of the filter, and the oil outlet of the filter is connected to the upper cylinder body main oil passage ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com