Vibration monitoring system and vibration monitoring method for divided conductors

A vibration monitoring system, a technology of splitting wires, applied in measuring devices, using wave/particle radiation, measuring ultrasonic/sonic/infrasonic waves, etc., can solve the limitations of applicability, can not be effectively used for dynamic monitoring of galloping and deicing jumps, and has not been seen Real-time monitoring of line torsional stiffness and other issues to achieve the effect of reducing friction and solving cross-sensitivity problems

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0031] The present invention will be further described in detail below in conjunction with the accompanying drawings.

[0032] like Image 6 As shown, the split conductor vibration monitoring system includes: a split conductor vibration monitoring device 25, an optical fiber 26, an optical fiber composite overhead ground wire 29, a fiber grating sensor 28 for temperature compensation, a fiber coupler 27, a fiber grating demodulator 30 and a computer System 31.

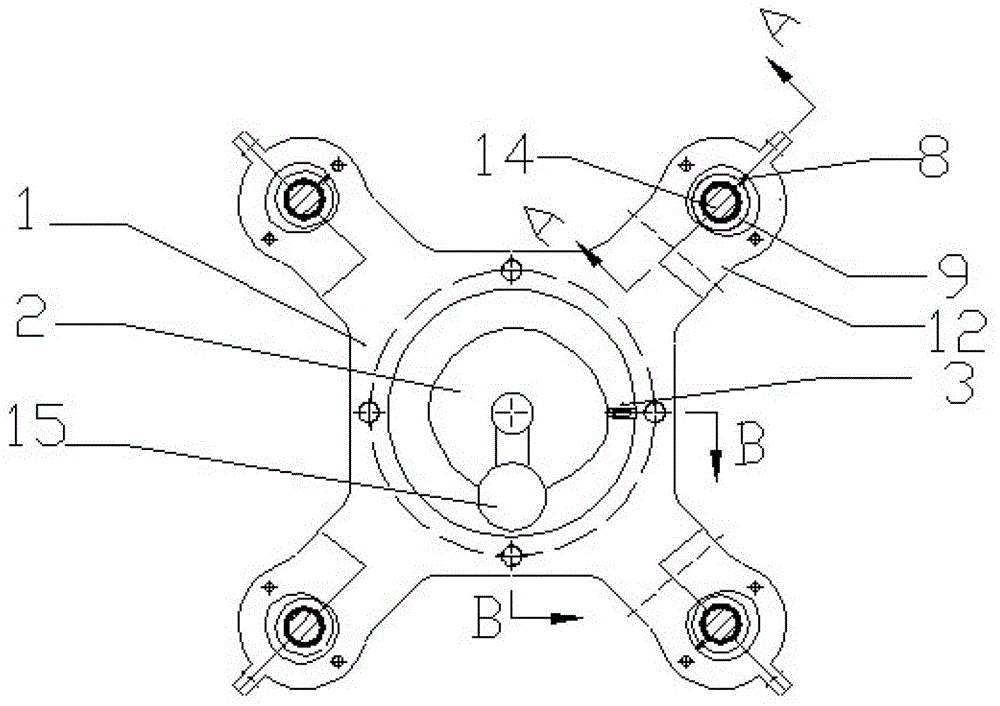

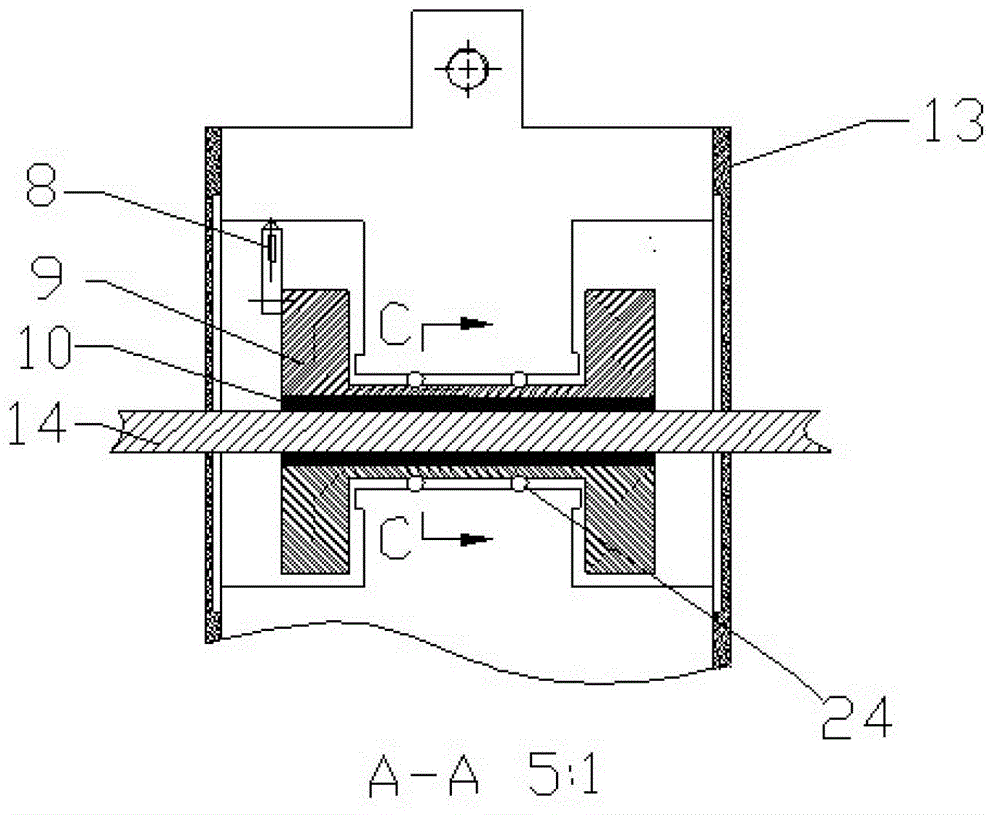

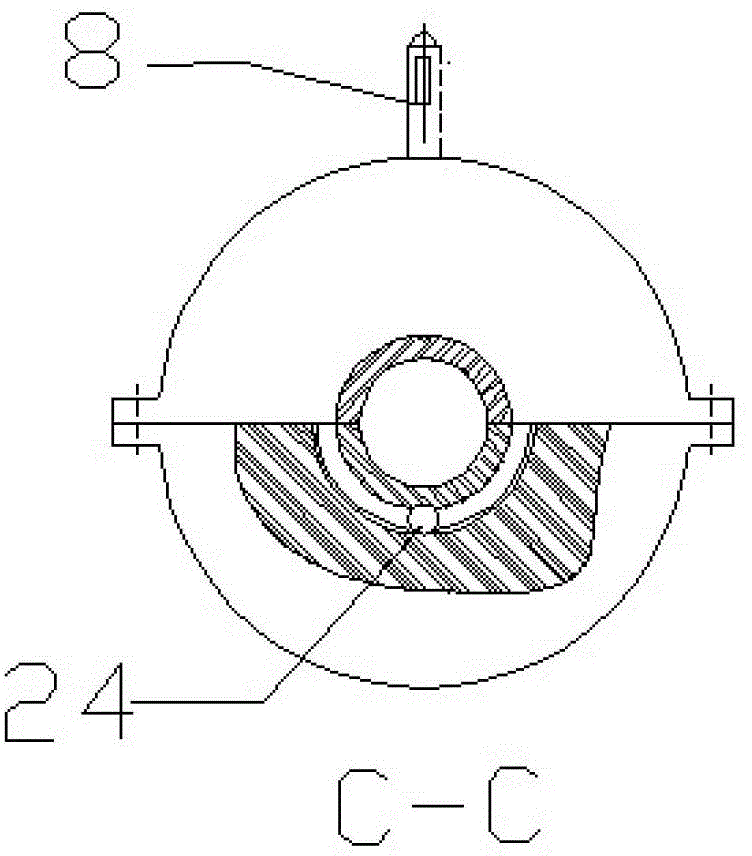

[0033] Among them, such as figure 1 and Figure 4 As shown, the split wire vibration monitoring device 25 includes: a split wire spacer skeleton 1, and the split wire spacer skeleton 1 is used to ensure the distance between each sub-wire; The middle section of the center hole of the wire spacer skeleton 1 is connected to ensure that the camshaft 2 can rotate relative to the skeleton 1, and one end of the camshaft 2 is connected to a spherical weight 15; the first fiber grating sensing unit 3 is fixed on the spacer s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com