Core gap and core rupture stress detection device

A technology of fracture stress and detection device, applied in the field of stress detection device for core fracture and core fracture, can solve the problems of high labor intensity, poor safety, inability to improve the permeability of core, and achieve safe operation and high success rate. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

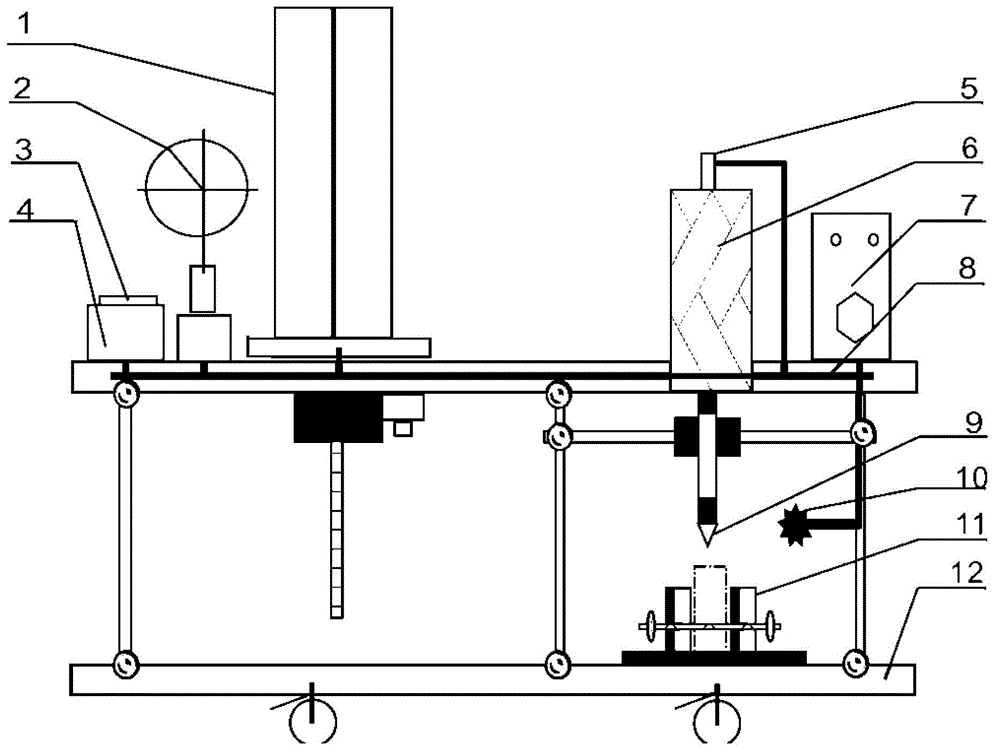

[0020] In order to better understand the purpose, structure and function of the present invention, a core fracture and core fracture stress detection device of the present invention will be described in further detail with reference to the accompanying drawings.

[0021] Such as figure 1 As shown, the core fracture and core fracture stress detection device of the present invention includes a core clamping device 11 and a core fracture cutter 9 arranged above the core clamping device 11, wherein the core clamping device 11 is used to fix the fractured core , So that it can be accurately aligned with the joint-making blade, and the core-making cutter 9 cracks the core through stress, creating conditions for later inspection.

[0022] In addition, the core fracture and core fracture stress detection device of the present invention also includes a main control device 7 and a hydraulic power system that is electrically connected to the main control device 7 through a transmission and co...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com