Water seepage collecting and testing system for fluid-solid coupling test

A test system and test chamber technology, applied in the direction of measuring devices, permeability/surface area analysis, suspension and porous material analysis, etc., can solve the lack of accurate test methods for material penetration rate and water seepage, and poor visibility of model test systems , Difficult to visually observe the test process and other problems, to achieve the effect of enhancing visualization, realizing intuitive observation, and ensuring accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

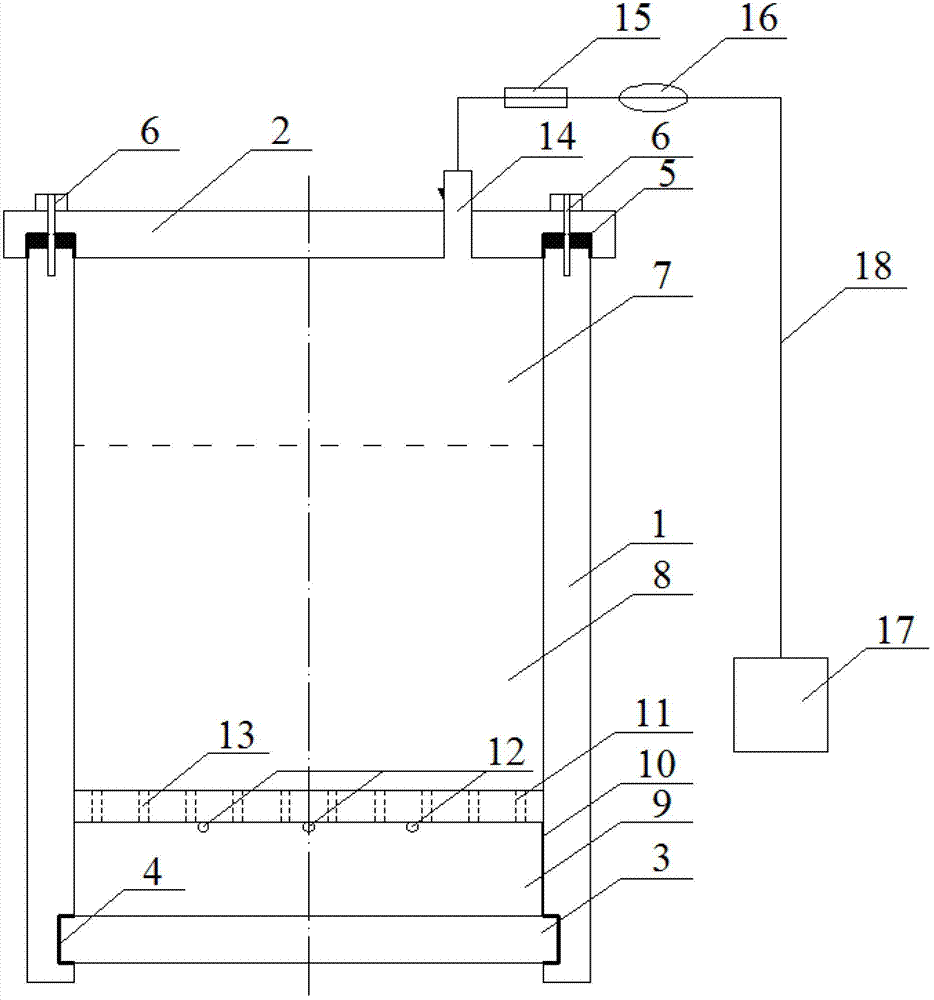

[0027] The present invention will be further described below in conjunction with the accompanying drawings.

[0028] In the figure, a water seepage collection test system for fluid-solid coupling test of visualized underground engineering model test, including a transparent model test box, the test box uses splicing and gluing technology to carry out waterproof and sealed design; the inside of the test box includes a The water tank area 7, the material area 8 and the water volume collection area 9 that are arranged successively below are three parts. The water tank area 7 is connected with the material area 8, and the overlying static water bodies of different heights are set. Similar materials are filled in the material area 8, and the material area 8 and the water collection area 9 are provided with a permeable partition 11 and a stainless steel pipe support 12, and a scale scale 10 is provided on the side wall of the water collection area 9; a water pressure control device i...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com