Double thrust electromagnet damping mechanism

A shock-absorbing mechanism and electromagnet technology, applied in the direction of electromagnets and electromagnets with armatures, can solve the problems of limited impact life and other problems, and achieve the effects of improving life expectancy, avoiding excessive impact sound and good buffering effect.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

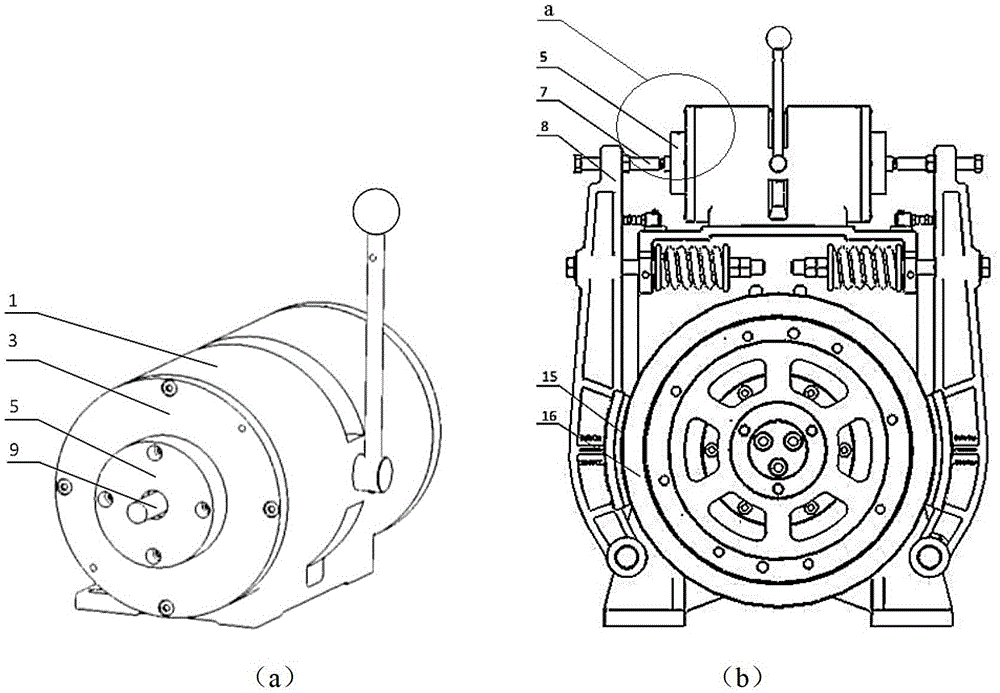

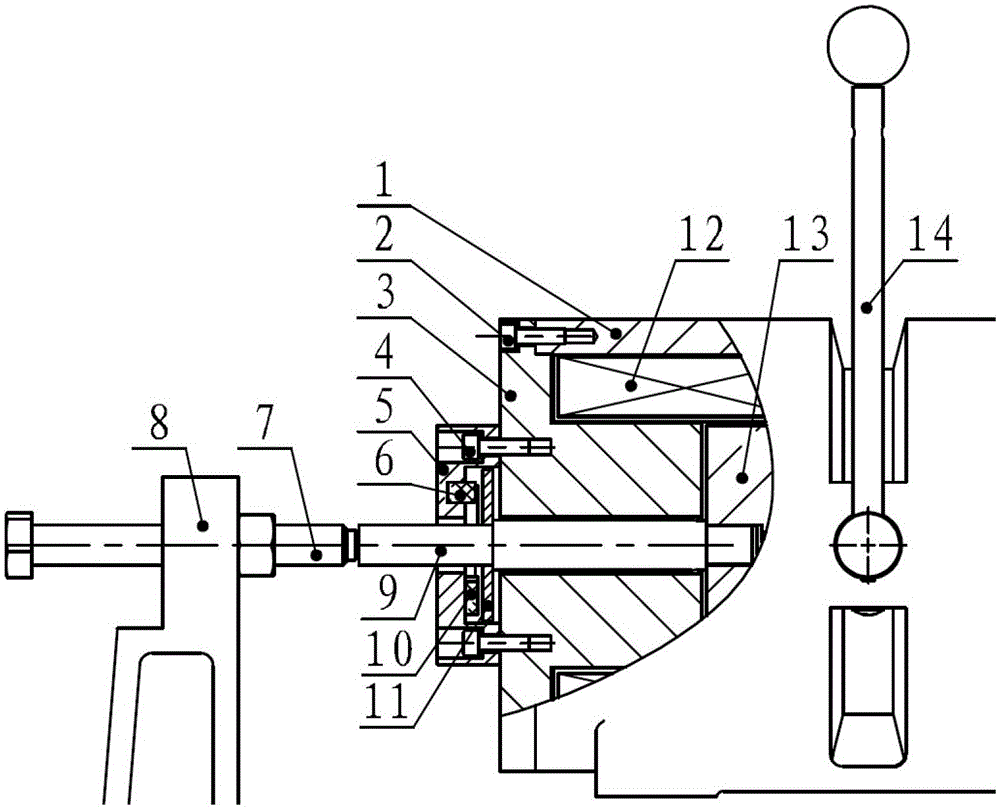

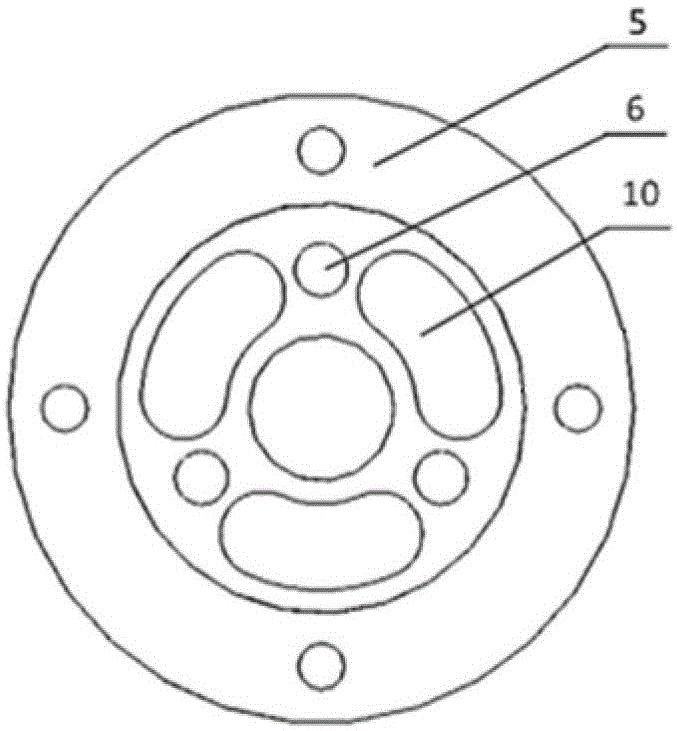

[0029] Such as figure 1 and figure 2 As shown, this embodiment is applied to a conventional electromagnetic braking elevator traction machine. Such as figure 2 As shown, the damping mechanism in this embodiment is symmetrically sleeved on the outside of the push rod 9 and arranged outside the electromagnet core 3. The damping mechanism on each side includes: a cover plate 5 and a bumper that are oppositely arranged and form a cavity. Plate 11, and the shock absorber 10 of the primary shock absorber and the shock absorber 6 of the secondary shock absorber which are arranged in the cavity and are composed of several shock absorbers, wherein: the cover plate 5 is fixedly connected with the iron core 3, The striking plate 11 is movably arranged between the cover plate 5 and the iron core 3, and the shock absorbing block 10 of the primary shock absorbing pad and the shock absorbing block 6 of the secondary shock absorbing pad are arranged centrally symmetrically with the push r...

Embodiment 2

[0039] Such as Figure 7 As shown, the multistage shock absorber of the present embodiment is a three-stage structure, wherein: the shock absorber 10 of the primary shock absorber, the shock absorber 6 of the secondary shock absorber, and the shock absorber 17 of the third stage shock absorber They are evenly distributed in the cover plate 5 in a centrally symmetrical manner, and the hardness of each level of shock absorbing pad and the height extending to between the cover plate 5 and the strike plate 11 are not the same, and the higher the hardness of the shock absorbing pad, it extends to the cover plate The height between the plate 5 and the strike plate 11 becomes smaller.

Embodiment 3

[0041] Such as Figure 8 As shown, the multistage shock absorber in this embodiment adopts any one of the following three implementations:

[0042] a) if Figure 8As shown in (a), the shock absorbing block 10 of the primary shock absorbing pad is inserted or screwed into the cover plate 5 , and the shock absorbing block 6 of the secondary shock absorbing pad is inserted or screwed into the striking plate 11 .

[0043] b) if Figure 8 As shown in (b), the shock absorber 10 of the primary shock absorber is inserted or screwed into the strike plate 11 , and the shock absorber 6 of the secondary shock absorber is inserted or screwed into the cover plate 5 .

[0044] c) if Figure 8 As shown in (c), the two-stage shock absorbing pads 10 and 6 are inserted or screwed into the striking plate 11 .

PUM

| Property | Measurement | Unit |

|---|---|---|

| tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap