Comb-tooth capacitor accurate assembly method based on bi-stable state compliant mechanism

A technology of flexible mechanism and assembly method, which is applied in the direction of capacitors, capacitor manufacturing, fixed capacitors, etc., and can solve problems such as difficulties in deep reactive ion etching manufacturing processes

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

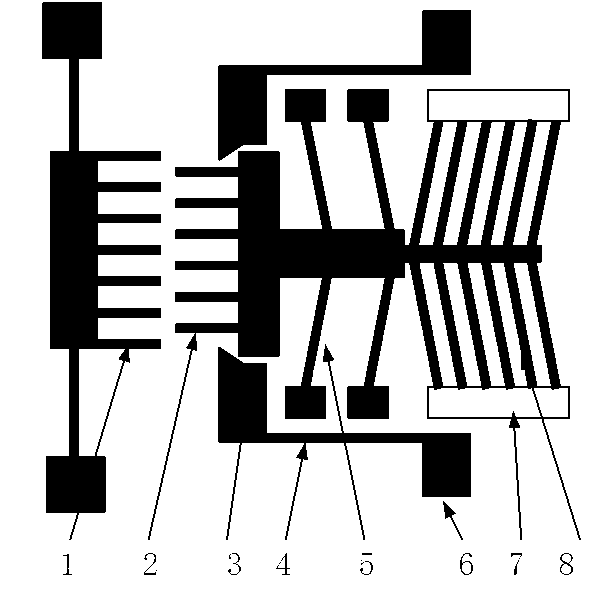

[0014] as attached figure 1 As shown, a comb capacitor precision assembly method based on bistable compliance mechanism is characterized in that the device includes: fixed comb 1, movable comb 2, locking block 3, elastic beam 4, bistable Compliant mechanism 5, support block 6, electrothermal driving electrode 7, micro-actuator 8 of electrothermal compliance mechanism.

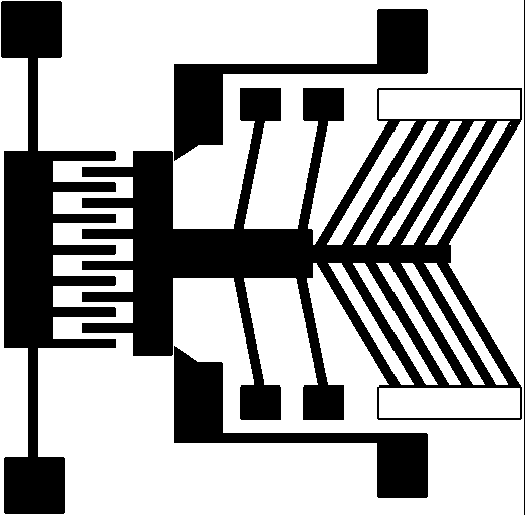

[0015] as attached figure 1 And attached figure 2 As shown, are the two static equilibrium configurations of the bistable compliance mechanism 5 before and after the assembly. Since the bistable compliance mechanism 5 has certain stability in its two static equilibrium configurations, when the device works in a vibrating environment, the position of the movable plate will not change, and stable locking can be realized.

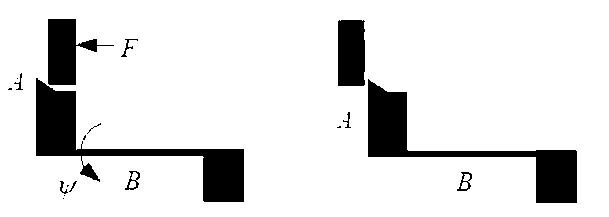

[0016] as attached image 3 As shown, the structure of the movable plate position locking block 3 adopts a V-shaped contraction groove structure at the end A, and a thin-walled cantilever ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com