Flapping device used for minitype loudspeaker device

A technology of micro-speaker and membrane device, applied in the direction of sensors, electrical components, etc., can solve the problems of poor mechanical rigidity, limited use range, insufficient structural rigidity, etc., to achieve good material selection adaptability and manufacturability, large technology expansion space, The effect of broadening the selection of materials

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] The technical solution of the present invention will be further described below in conjunction with the accompanying drawings and a preferred embodiment.

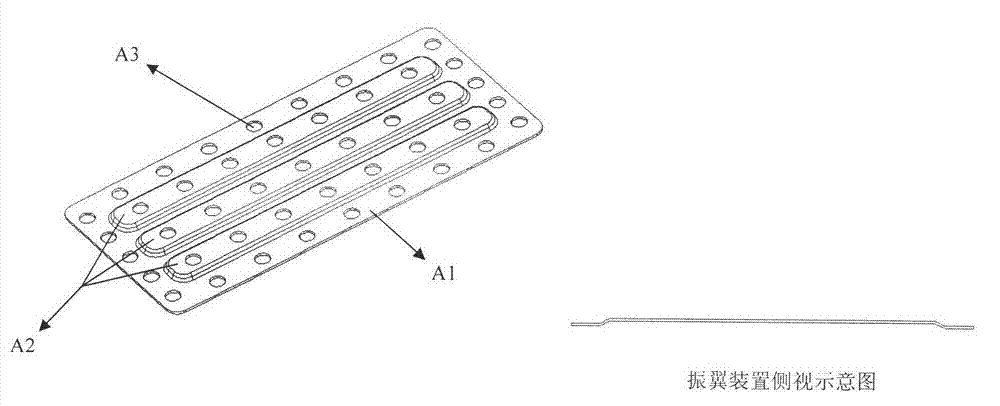

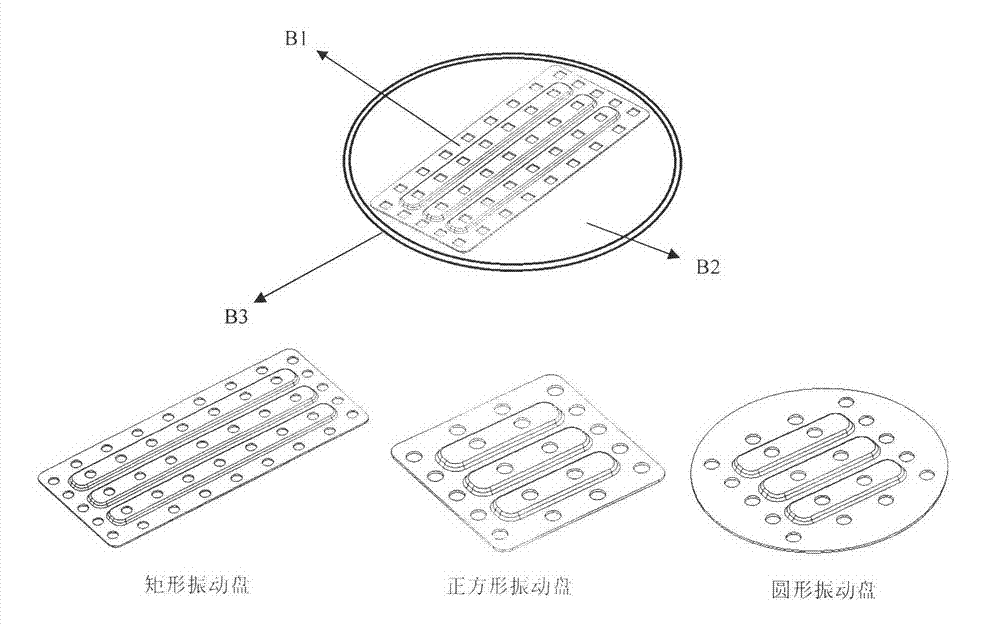

[0023] refer to figure 2 , 3 , the present embodiment relates to a flapping device B1 applied to a micro-speaker device, which includes a vibrating plate part A1, a mechanical structure rib part A2 and a through-hole structure A3. The aforementioned vibrating plate part A1 is a planar structure, according to the designed It is required to have a mechanical structure reinforcing rib part A2 on the vibrating plate A1, and at the same time, a number of through-hole structures A3 are distributed on the vibrating plate A1 and the mechanical structure reinforcing rib part A2, which jointly constitute the flapping device B1.

[0024] Due to the planar structure of the vibrating plate part A1 and the convex or concave structure of the mechanical structure reinforcing rib part A2 and the own characteristics of the through h...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com