Manufacture method of thick copper plate fine solder resist bridge

A manufacturing method and technology of solder mask bridges, which are applied in printed circuit manufacturing, electrical components, printed circuits, etc., can solve the problems of low efficiency, low yield, and poor product appearance of fine green oil bridges, so as to avoid appearance defects, Effects that satisfy the thickness condition

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] The present invention provides a method for manufacturing a fine solder-resisting bridge of thick copper plate. In order to make the purpose, technical solution and effect of the present invention clearer and clearer, the present invention will be further described in detail below. It should be understood that the specific embodiments described here are only used to explain the present invention, not to limit the present invention.

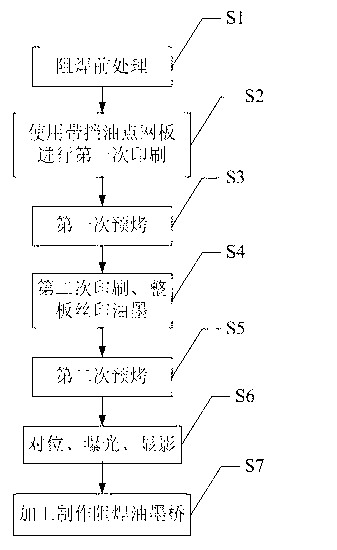

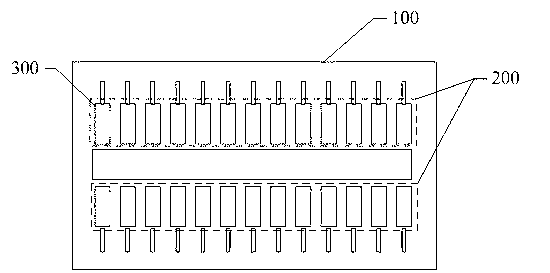

[0020] A method for manufacturing fine solder-resisting bridges for thick copper plates of the present invention is used for processing thick copper plates with a thickness ≥ 2 OZ, and the width of the processed solder-resisting ink bridges is ≤ 4 mils. Solder-resist bridges less than 4mil often cause processing quality degradation due to side erosion during printing ink, and this method can avoid the occurrence of this problem. The method adopted by this method includes the following steps: use oil-repelling points for thick copper circuit ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com