Hydraulic axis

A hydraulic shaft, hydraulic technology, applied in the direction of presses, fluid pressure actuation devices, servo motors, etc., can solve problems such as large prestressing equipment costs and so on

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

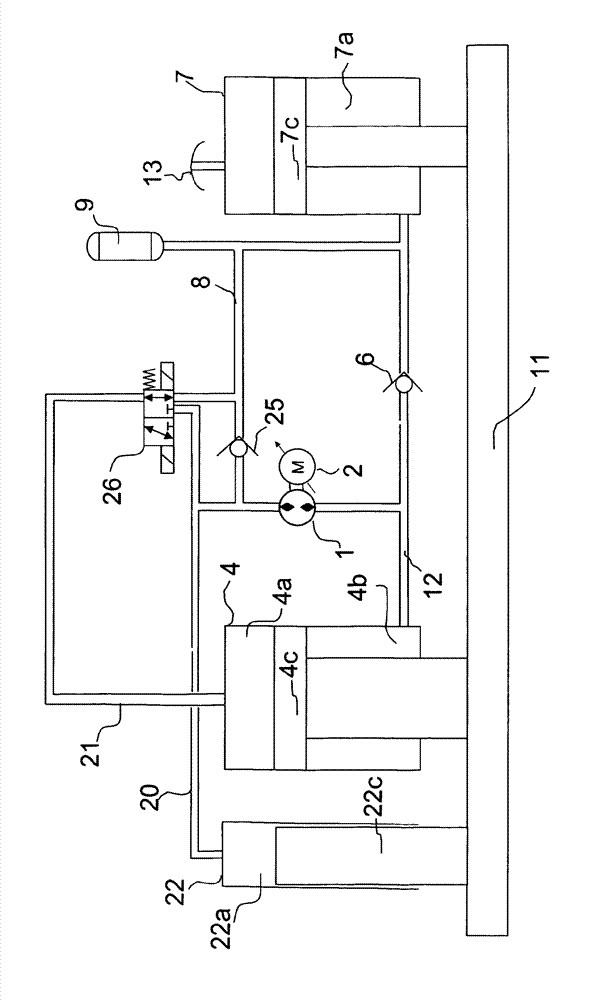

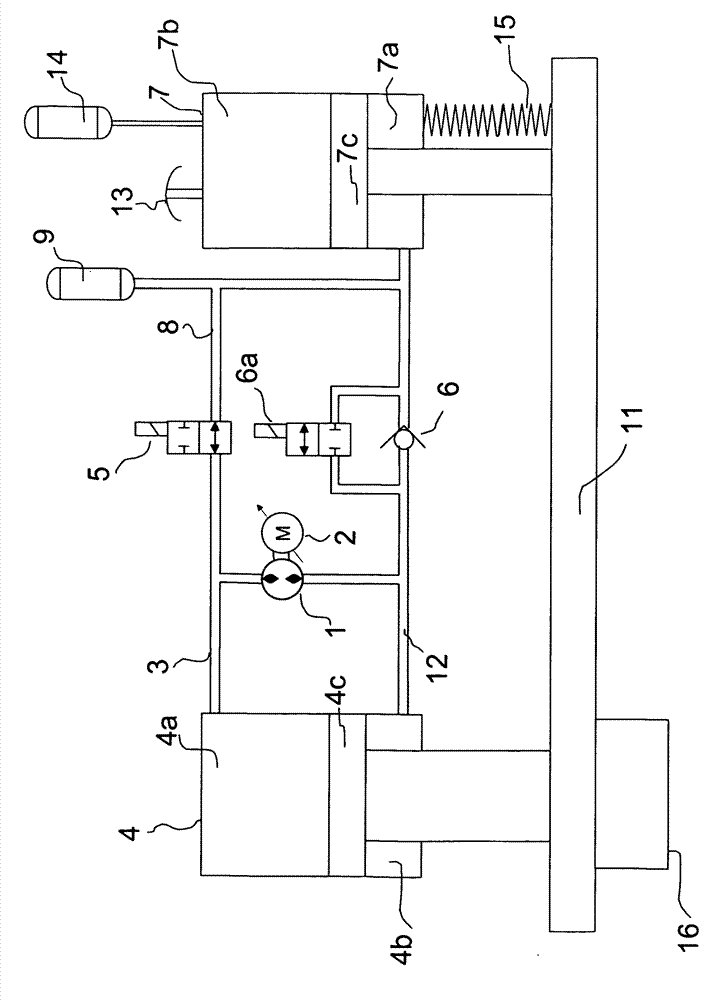

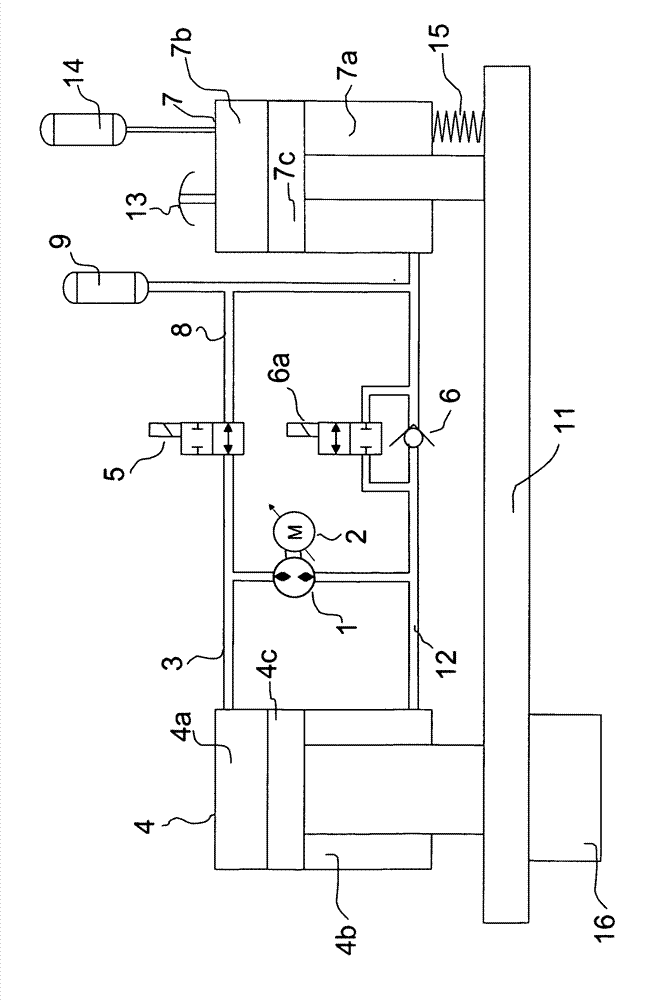

[0066] FIG. 1 shows a schematic circuit diagram of a hydraulic drive device in a static state according to a preferred first embodiment of the present invention.

[0067] As can be seen from all the figures, the hydraulic drive according to the invention has a pump in the form of a variably driven hydraulic machine 1 which is here mechanically connected to an electric motor 2 . The hydraulic machine 1 is connected at its two pressure connections to a hydraulic pressure line system which forms a closed hydraulic circuit.

[0068] In particular, a connecting line 3 is connected to the first pressure connection of the hydraulic machine 1 , which leads directly to the piston-side pressure chamber 4 a of the master cylinder 4 . Connected to the second pressure connection of the hydraulic machine 1 is a second line 12 , which is connected to a pressure chamber 4 b on the piston rod side of the master cylinder 4 (hereinafter referred to as annular chamber 4 b ). Furthermore, line 12...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com