Multi-force-field dry magnetic separator

A magnetic separator, dry technology, applied in the direction of magnetic separation, solid separation, chemical instruments and methods, etc., can solve the problems of non-magnetic inclusions, unsatisfactory mineral grades, etc., and achieve the effect of avoiding environmental pollution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

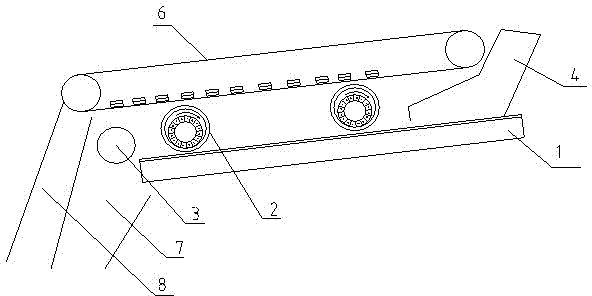

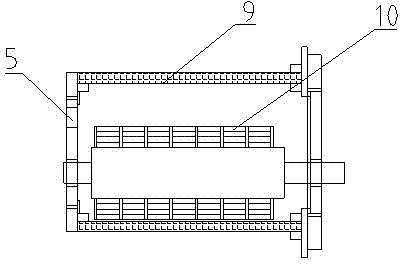

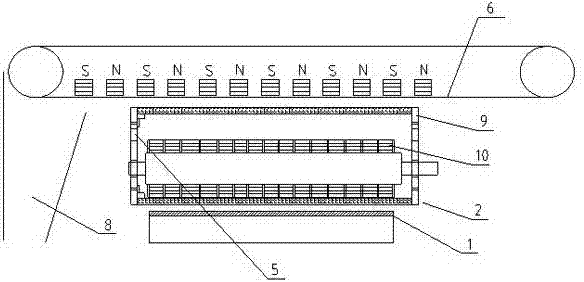

[0033] like figure 1 and figure 2 As shown, a multi-force field dry magnetic separator includes a feeding device 1 and a discharge belt 6 placed above the working surface of the feeding device 1. A magnetic system is installed on the inside of the discharge belt 6. The feeding end of the feeding device 1 The feed port 4 is set, the tailing port 7 is set at the discharge end, the concentrate port 8 is set at the discharge end of the discharge belt 6, and a rotating air-permeable magnetic roller is set between the working surface of the feeding device 1 and the working surface of the discharge belt 6 Cylinder 2, the air-permeable magnetic roller 2 includes a cylinder body 9 and a magnetic system 10 eccentrically arranged in the cylinder body 9, the wrap angle of the magnetic system 10 is 360°, the cylinder body 9 is made of a non-magnetic permeable plate, and The end surface of the cylinder body 9 is provided with an air inlet 5 and connected to the pressure gas. The discharge...

Embodiment 2

[0039] like Figure 4 As shown, this embodiment increases the number of air-permeable magnetic rollers 2 connected in series in the vertical direction on the basis of the first embodiment, that is, the air-permeable magnetic rollers 2a2 are connected in series in the vertical direction of the two air-permeable magnetic rollers 2a1 and 2b1 , 2b2. The sorting process of the materials in this embodiment is similar to that in Embodiment 1, that is, when the materials pass through the air-permeable magnetic rollers 2a1, 2b1, they are adsorbed to the surface of the air-permeable magnetic rollers 2a1, 2b1 and move upwards with them. When the air-permeable magnetic rollers 2a2 and 2b2 are in the magnetic force area, the magnetic material is turned over and adsorbed to its surface, and the non-magnetic material falls on the surface of the feeding device 1 under the action of gravity and wind force and finally falls into the tailings mouth 7, and the magnetic material is connected in se...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Wrap angle | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com