Pressure double closed loop control method for roll gap position of cold-rolling mill

A double closed-loop control, cold rolling mill technology, applied in the field of cold-rolled strip rolling, can solve problems such as excessive adjustment of the inclination setting value and quality defects of the edge of the strip.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

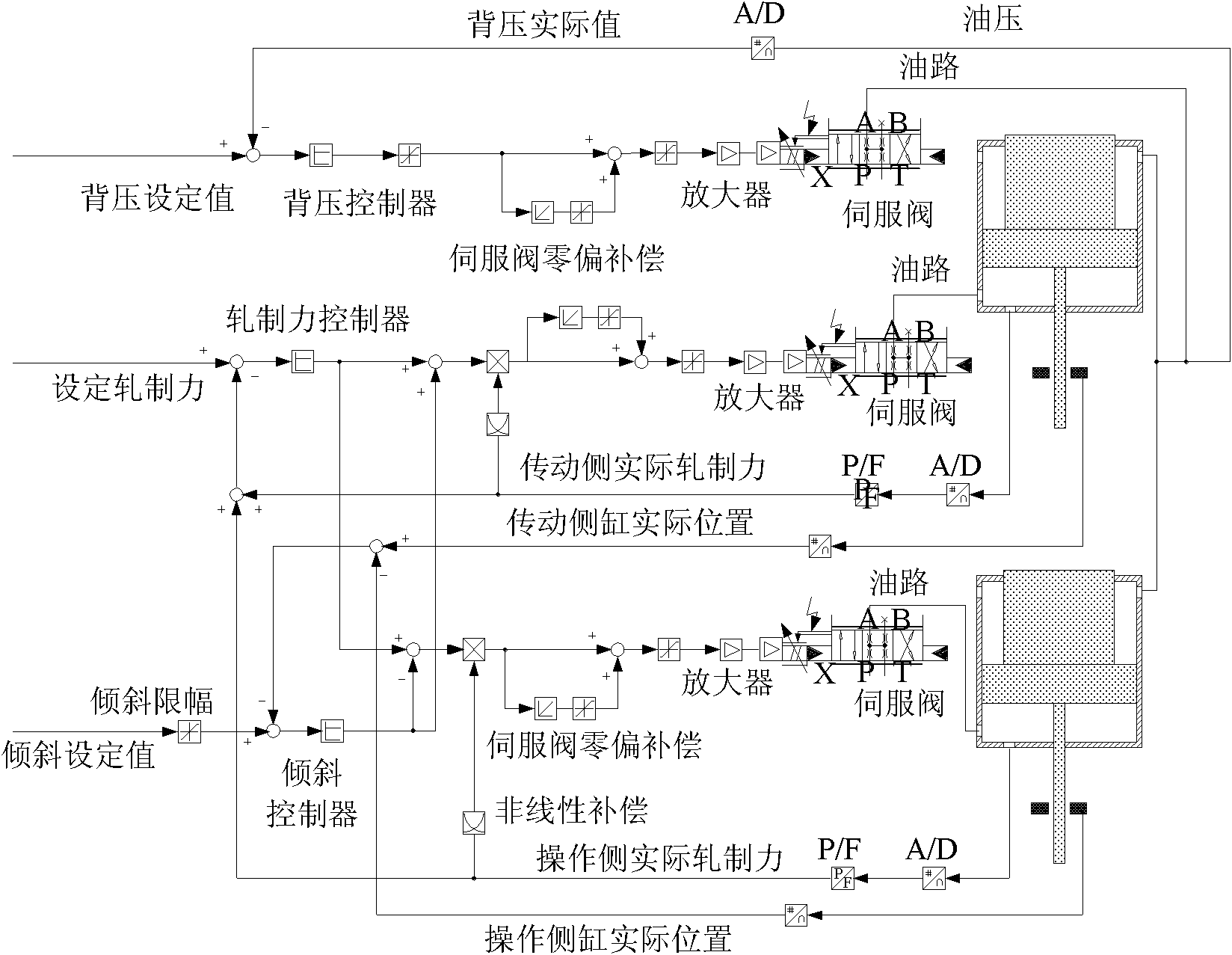

Method used

Image

Examples

Embodiment

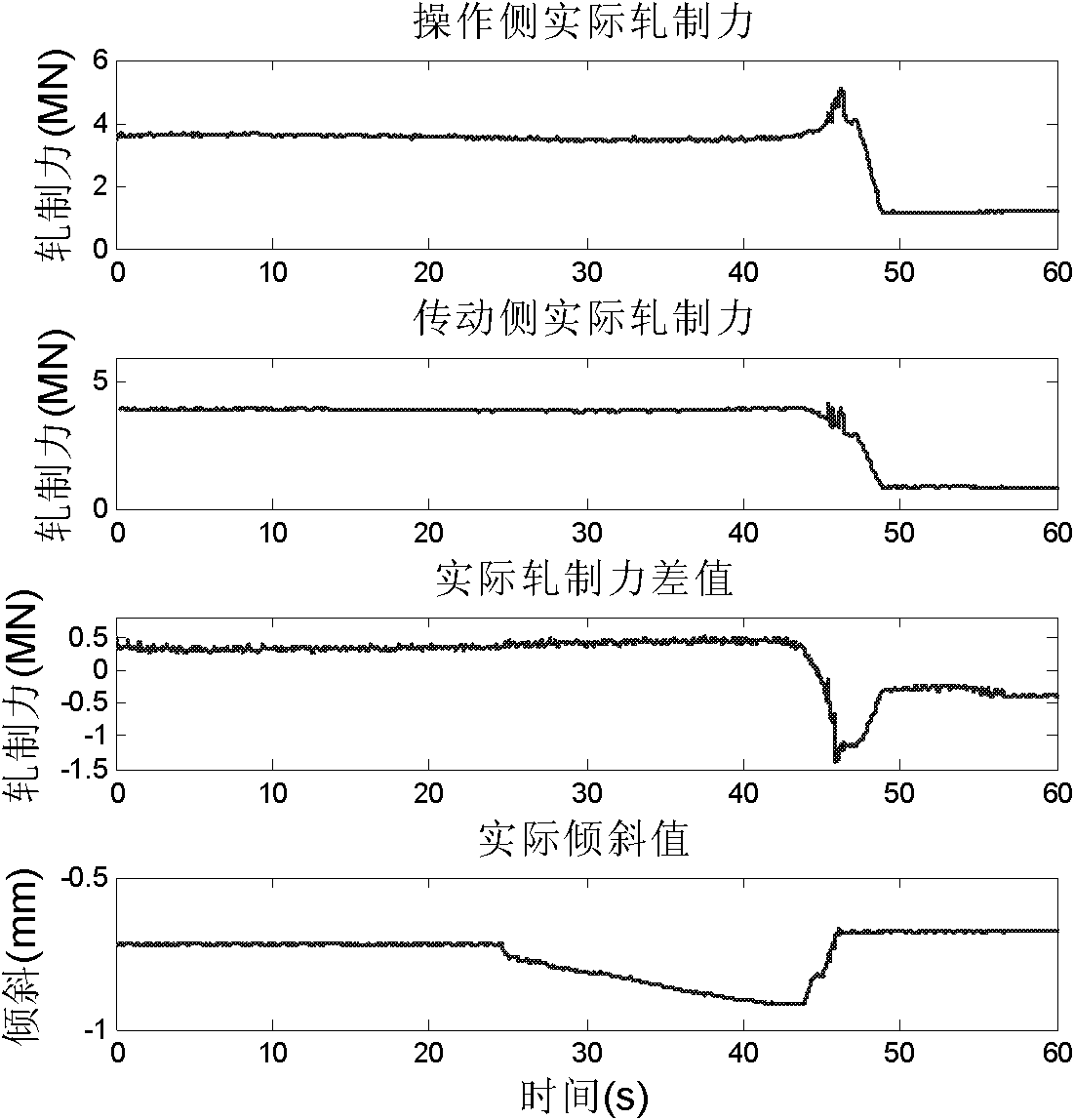

[0244] Example: According to the actual strip entrance thickness, exit thickness, reduction, deformation resistance, strip width, exit set tension, entrance set tension, work roll and back-up roll diameter, work roll and back-up roll crown Pre-calculate the relationship between the inclination and the rolling force difference on both sides, taking the rolling force difference as the independent variable and the inclination as the dependent variable, and use polynomial fitting to obtain the rolling force difference and inclination functional relationship

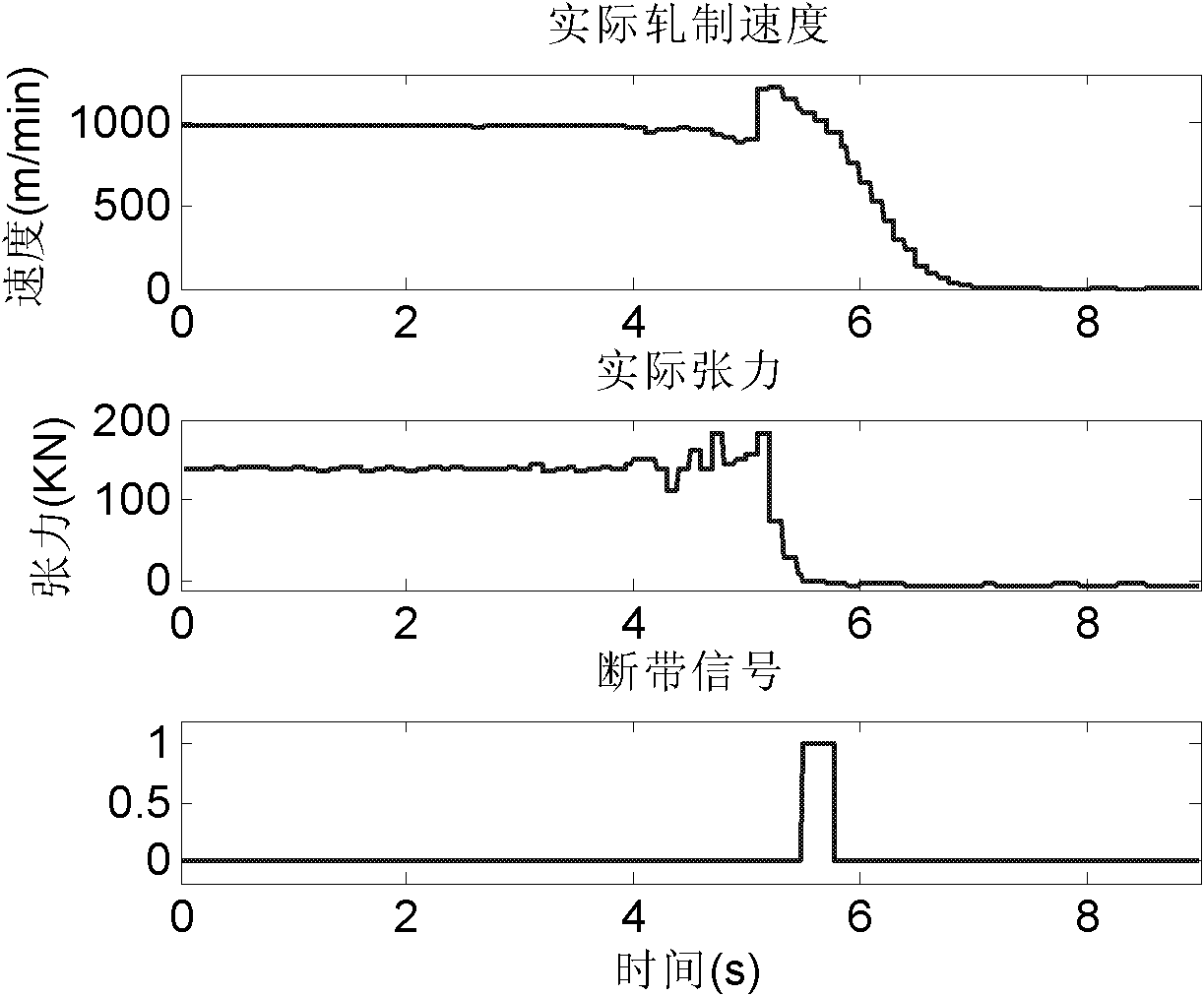

[0245] In application, according to the actual detection of rolling force difference ΔE on both sides DO , Calculate the inclination value of the roll through the above formula, and use it as the limit of setting the inclination value. When cracks appear in the strip steel, the shape of the raw material leads to tension difference on both sides or the accuracy of the detection element of the plate shape system decreases, r...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com