Fully-automatic apple sleeving machine and using method thereof

A set of machine, fully automatic technology, applied in the direction of packaging automatic control, packaging, packaging food, etc., can solve the problems of low accuracy, slow speed, low efficiency, etc., and achieve the effect of improving efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0073] A fully automatic apple wrapping machine proposed by the present invention and its use method will be further described in detail below in conjunction with the accompanying drawings and specific embodiments. Advantages and features of the present invention will be apparent from the following description and claims. It should be noted that all the drawings are in a very simplified form and use imprecise scales, and are only used to facilitate and clearly assist the purpose of illustrating the embodiments of the present invention.

[0074] Such as figure 1 with figure 2 Shown, a kind of fully automatic apple suiting machine, comprises:

[0075] Net sheath 11, wherein, said net sheath 11 comprises several long net sheaths;

[0076] A box shell 12 located below the mesh shell 11;

[0077] An annular frame 13 connected to the box shell 12;

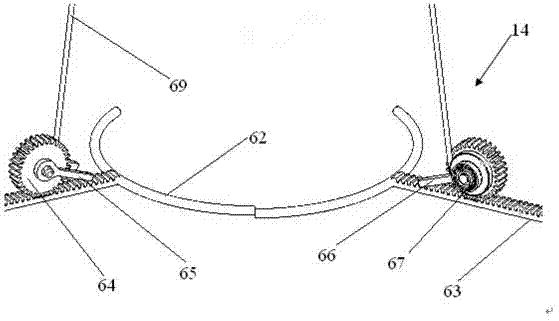

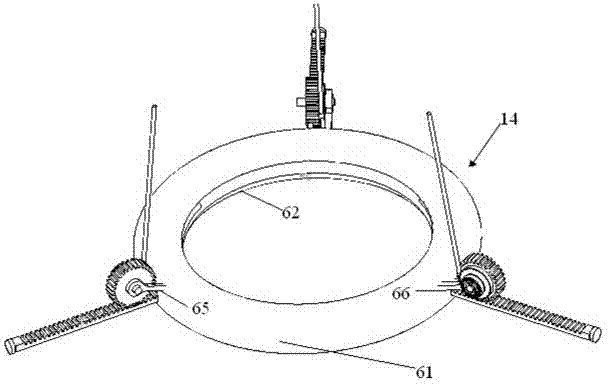

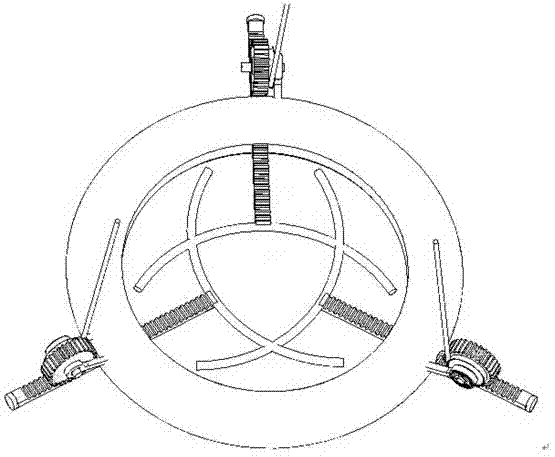

[0078] The mobile set structure 14 located outside the circular frame 13;

[0079] A first stepping motor 16 connected to the mo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com