Piling car with rotatable pallet fork

A stacker truck and fork technology, which is applied in the field of material transportation industrial vehicles, can solve the problems of high cost, large space, bulky, etc., and achieve the effect of improving efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

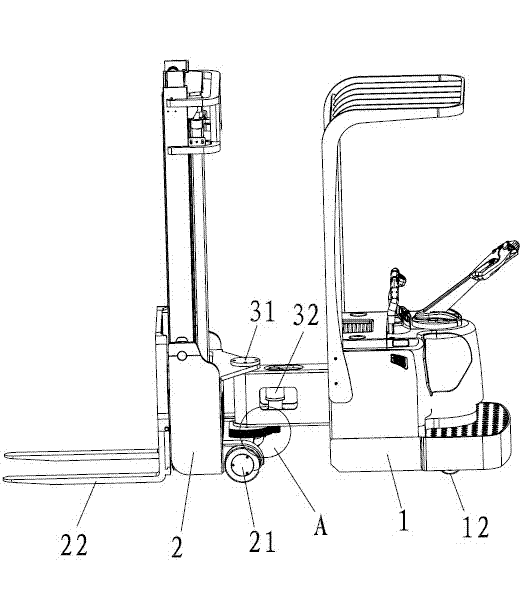

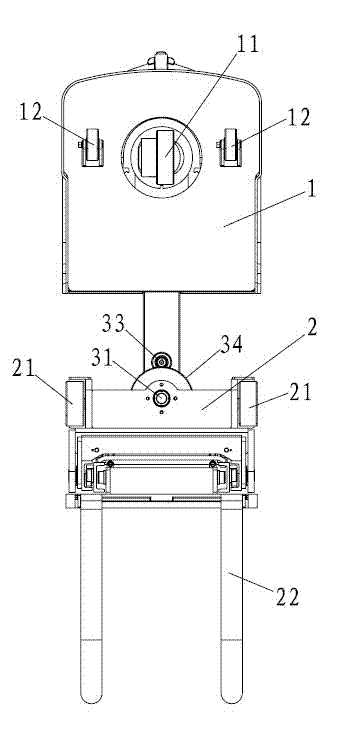

[0023] Embodiment 1: as Figure 1-4 As shown, a pallet truck with a rotatable fork includes a vehicle body 1 with a wheel set 11 at the lower part and a lifting system 2 with load-bearing wheels 21 at the lower part, and the vehicle body 1 is also provided with a steering mechanism for controlling the steering of the wheel set 11; Between the vehicle body 1 and the lifting system 2, there is an actuator that can make the lifting system 2 and the body 1 produce relative angular displacement; Control system for deflection direction and amplitude; the axial direction of load-carrying wheel 21 is always perpendicular to the orientation of fork 22 on lifting system 2, so load-carrying wheel 21 turns in the same direction synchronously with lifting system 2; steering mechanism and control system are shown in Fig. not shown in

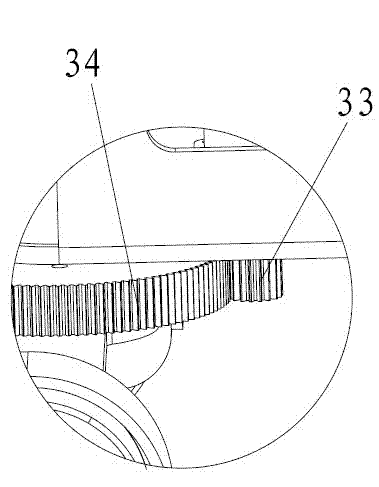

[0024] The actuator includes a rotating shaft 31 that rotatably connects the vehicle body 1 with the lifting system 2, the rotating shaft 31 is fixedly conn...

Embodiment 2

[0029] Embodiment 2: The difference from Embodiment 1 is that the rotating shaft 31 is not fixed to the lifting system 2 , but is fixed to the vehicle body 1 ; the driven gear 34 is not fixed to the rotating shaft 31 , but is fixed to the lifting system 2 .

[0030] The present invention is not only applicable to the stacker truck using the wheel set 11 as the driving wheel, but also applicable to the stacker truck using the load-bearing wheel 21 as the driving wheel; the rotating shaft 31 can be fixed to the vehicle body 1 or to the lifting system 2 , can also be flexibly connected to the vehicle body 1 or the lifting system 2; the power source in the embodiment can be a motor, a motor, etc.; the actuator in the embodiment can also be a hydraulic motor, a rack and pinion cylinder and other structural types.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com