Clean room for semiconductor plant

A semiconductor and clean room technology, applied in the field of clean rooms, can solve the problems of hindering personnel movement, difficult to grasp the distance, time-consuming and laborious, etc., to avoid the impact of storage bins and products, facilitate construction, and reduce costs.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

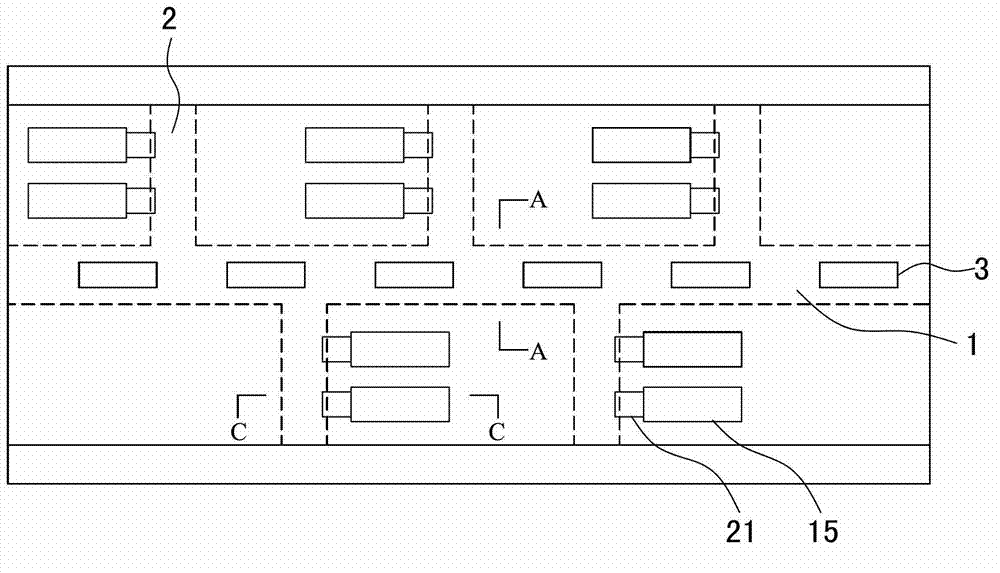

[0041] see Figure 4~6 As shown, a clean room for a semiconductor plant, including a fresh air delivery system, an exhaust system and a large clean space, the large clean space has a central aisle 1 and 5 production aisles 2;

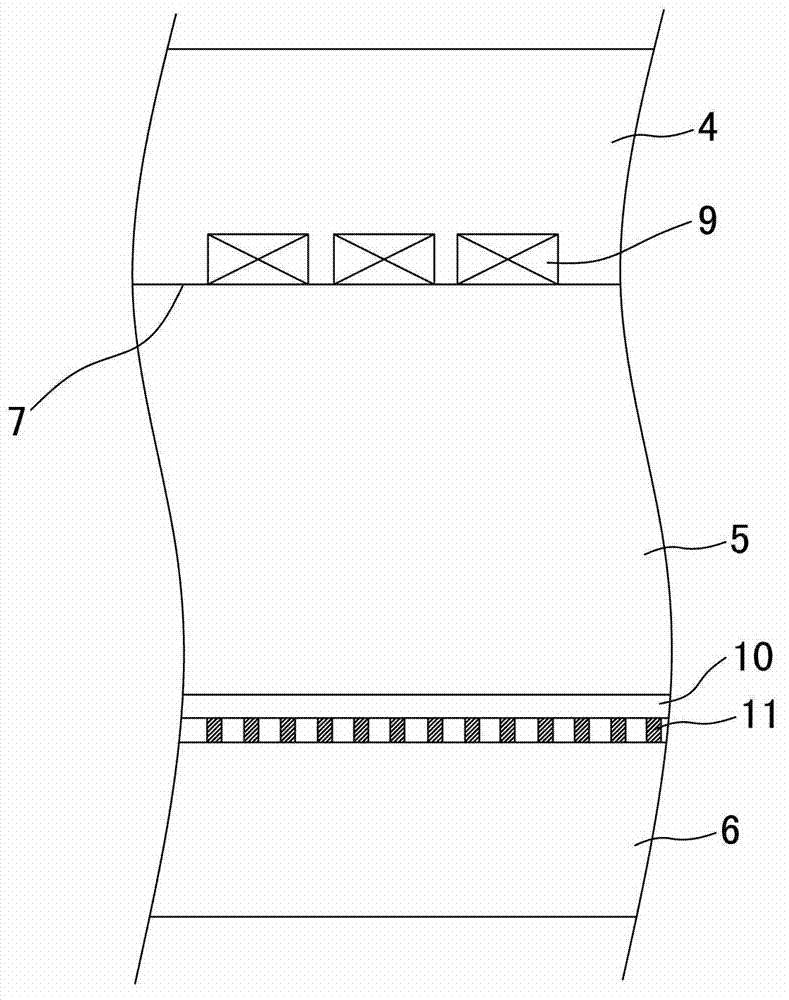

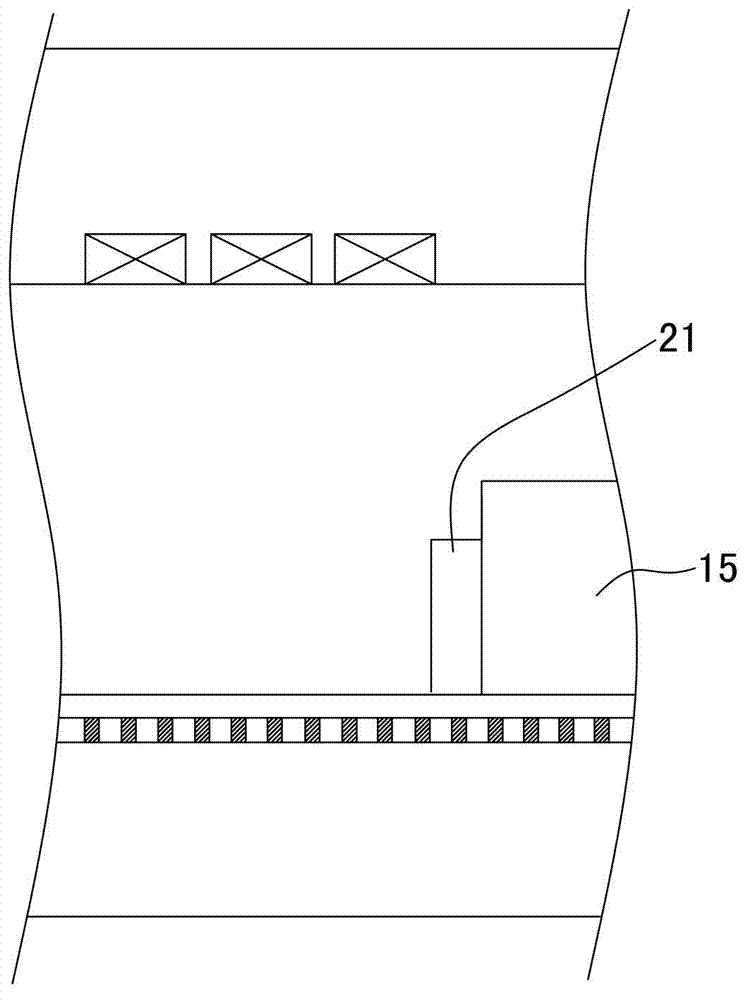

[0042] The large clean space includes a structure space 4, a clean space 5 and a circulation space 6 from top to bottom, a ceiling 7 is provided between the structure space and the clean space, and a raised floor 10 and a concrete slab 11 are provided between the clean space and the circulation space ;

[0043] Partitions 8 are arranged around the production walkway, so that at least a part of the architectural space, the clean space, and the space where the raised floor is located form an independent clean micro-environment structure; the distance between the bottom of the partition and the ceiling is 60cm, and the distance between the bottom of the partition and the raised floor is 2m;

[0044] The top of the clean microenvironment is provided with ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com