Transmission clutch assembly with whistling reduction technology

A technology for clutches and transmissions, applied in clutches, fluid-driven clutches, non-mechanical drive clutches, etc., can solve problems such as energy loss and low efficiency, and achieve the effect of reducing vibration and reducing vibration

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

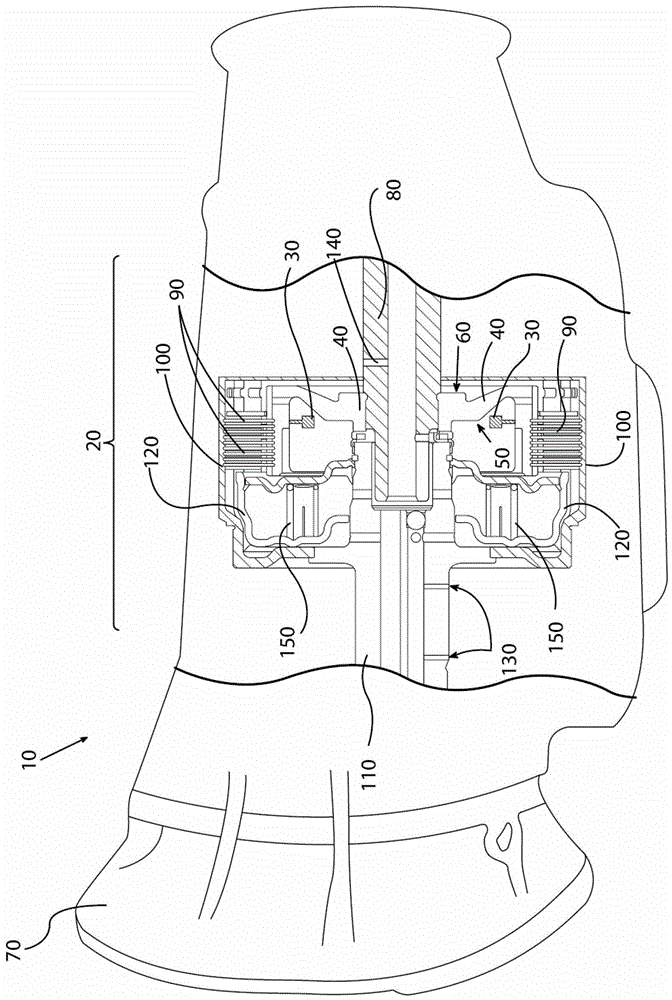

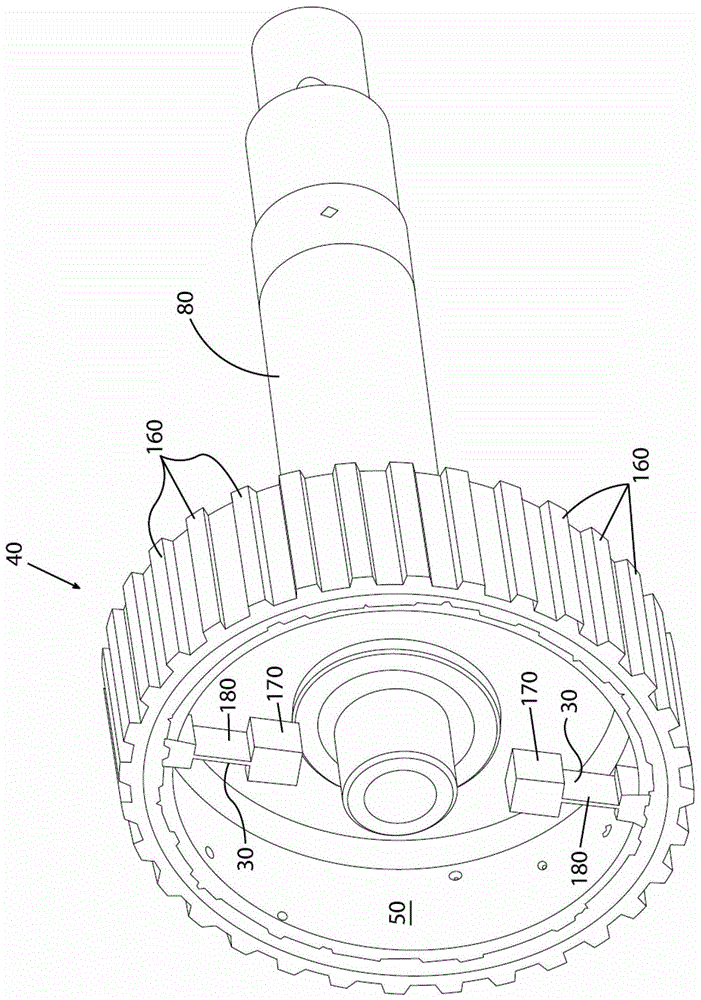

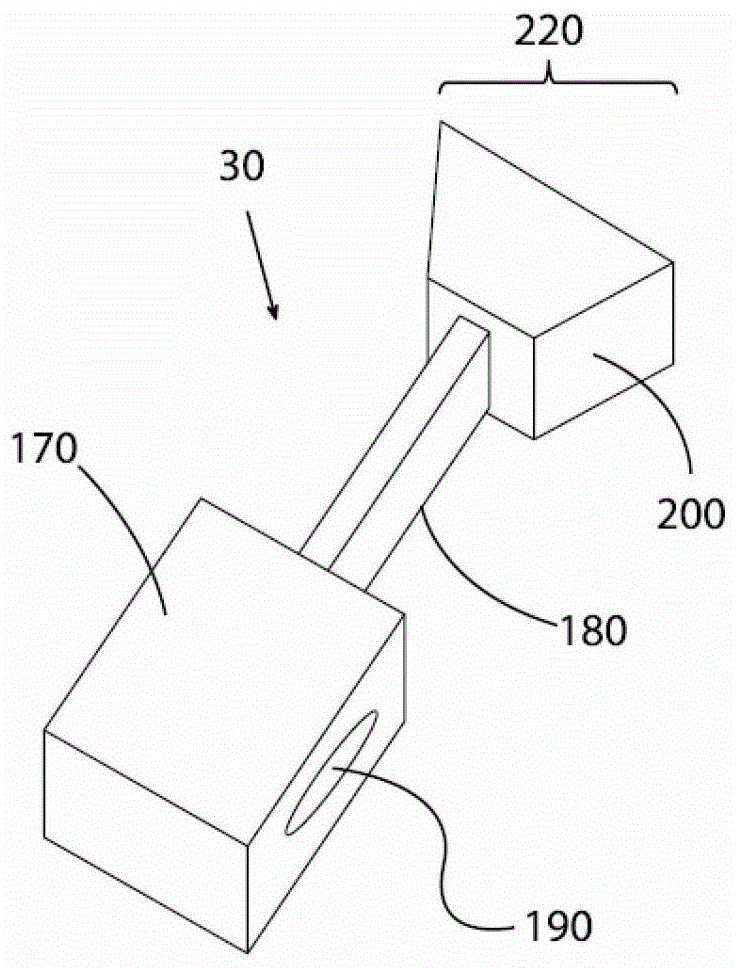

[0025] Referring to the drawings, there are shown different embodiments of a vehicle transmission clutch assembly implementing improved squeal reduction technology, like symbols denoting like or corresponding parts throughout the views. Significant noise reduction is achieved through the use of a set of mass dampers in the clutch assembly. The mass damper changes the vibration pattern of the clutch gears during engagement, thereby reducing the noise output during shifting. Mass dampers are connected to different clutch packs. Exemplary clutch assemblies with mass dampers attached are illustrated as clutch gears, clutch hubs, or pistons. Different types of mass dampers are also compatible with clutch packs shown or not shown. In one embodiment, for example, the damper is a sprung mass damper coupled to a clutch gear. In certain embodiments, the use of sprung mass dampers allows for multi-directional vibration control. Embodiments with sprung mass dampers have a dual functio...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com