Uniform rotation and axial force control method for bearing axial protrusion detection

A control method and technology of axial force, applied in the direction of measuring devices, instruments, etc., can solve the problems of poor stability of manual rotating mandrel, affecting the accuracy of axial projection of bearings, and axial force cannot be read intuitively, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

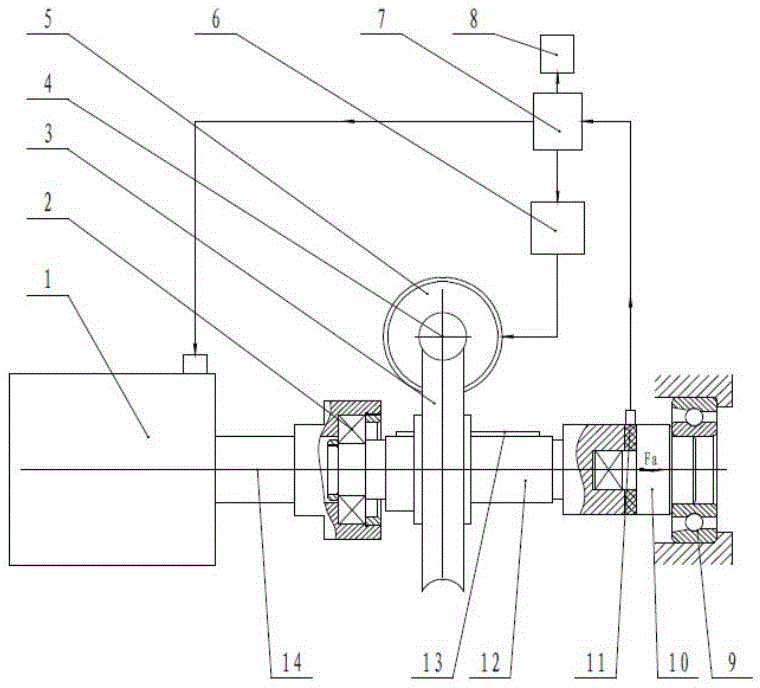

[0019] The invention is a uniform rotation and axial force control method for the detection of the axial protrusion of the bearing. The control method of the invention can realize the uniform rotation of the tested bearing through a set of detection devices, and can control the measured bearing under the uniform rotation. The axial force that can be monitored is applied to the inner ring of the tested bearing, which improves the detection accuracy of the axial protrusion of the tested bearing. The control method is simple and practical.

[0020] The axial protrusion of the bearing means: when the other end surface of the outer ring is fixed and one end surface of the inner ring is positioned and rotates at a constant speed, combined with figure 1 The other end surface refers to the right end surface of the outer ring and the inner ring, and the one end surface refers to the left end surface of the outer ring and the inner ring. The same applies hereinafter. A permissible axial...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com