Method for detecting gas flow rate through weight loss method

A technology of gas flow and detection method, applied in liquid/fluid solid measurement, measurement flow/mass flow, measurement device, etc., can solve the problems of harsh installation conditions of glass rotor flowmeter, troublesome data conversion and comparison, and cumbersome installation process. , to achieve the effect of good testing site and environmental adaptability, testing safety, and a wide range of applications

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

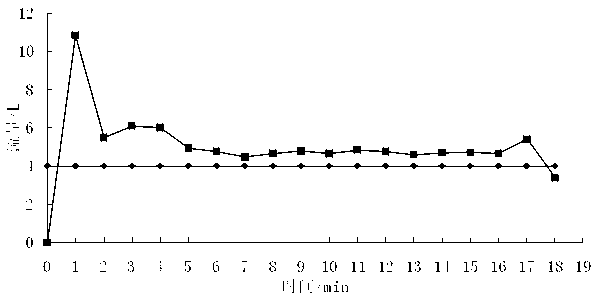

[0015] The specific implementation of the present invention will be described by taking the detection of the gas flow rate of a certain solid oxygen generator as an example.

[0016] Step 1, establish a dynamic connection: Prepare a laptop computer and a precision electronic balance, connect them through a dedicated RS232 interface and a data cable, start the real-time weighing software on the computer, select the corresponding balance model, and establish a dynamic connection.

[0017] Step 2, start the gas generator and start timing and weighing: put the solid oxygen generator on the balance tray, reset the mass to zero, and clear the time and data of the real-time weighing software; start the solid oxygen generator, and the generator starts to generate oxygen , the quality keeps decreasing, and the real-time weighing software starts timing and records the quality data. In this example, according to the measurement accuracy requirements, it is set to record a quality data ev...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com