Fiber grating force-measuring anchor rod device

A fiber grating and anchor technology, which is applied in the direction of measuring the change of optical properties of materials when they are stressed, can solve the problems of poor reliability, short transmission distance, and low measurement accuracy, and achieve increased reliability and resistance. Strong electromagnetic interference, good anti-lightning performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0013] The present invention will be further described below in conjunction with the accompanying drawings and embodiments.

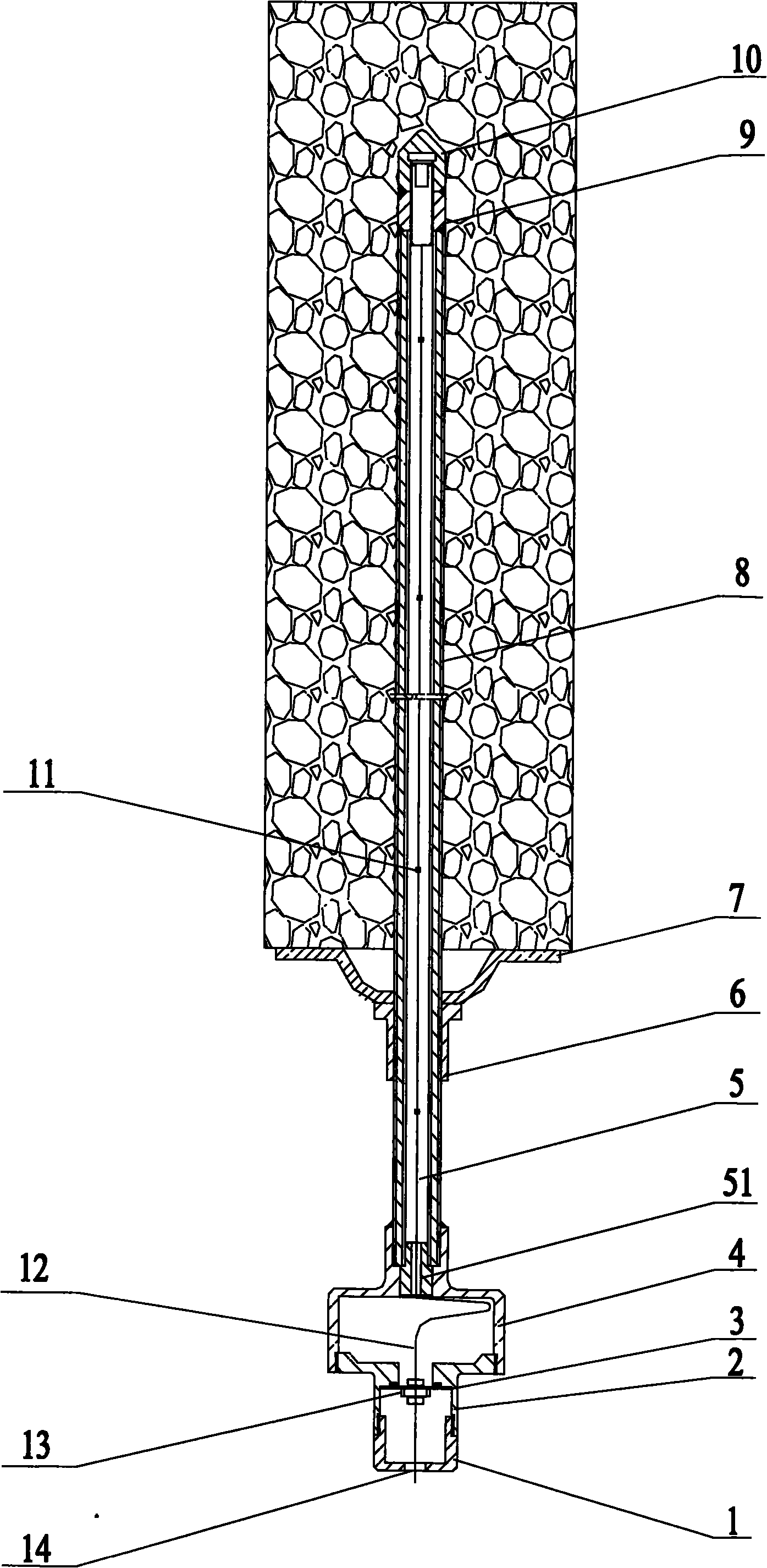

[0014] In this example, if figure 1 As shown, the main body of the anchor device includes an optical fiber 12, a rod beam 5, and a hollow anchor rod 8. Four gratings 11 are arranged on the optical fiber 12, and the distance between every two gratings 11 is 500 mm. Each grating 11 is pasted on the rod beam. 5, one end of the rod beam 5 is threaded, and the other end is a limiting block 51, the outer diameter of the limiting block 51 is greater than the inner diameter of the hollow anchor rod 8, and the rod beam 5 pasted with the grating 11 passes through the hollow anchor rod 8, The stopper 51 is stuck on one end of the hollow anchor rod 8, and a fastening nut 9 and an end nut 10 are arranged at the other end of the hollow anchor rod 8, and both the fastening nut 9 and the end nut 10 are threadedly connected with the beam 5 , under the combined action o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com