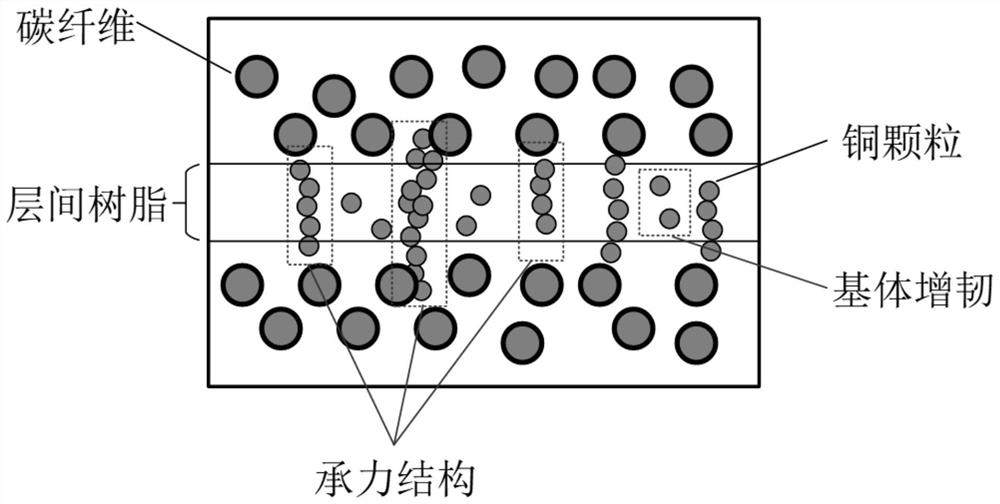

Interlayer performance enhanced carbon fiber composite material based on dielectrophoresis and preparation method thereof

A composite material and interlayer performance technology, which is applied in the field of carbon fiber composite materials, can solve the problems of deteriorating composite interlayer mechanical strength, enhancing electrical conductivity/strength, etc., to optimize lightning strike resistance, improve impact strength, and enhance mechanical strength. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0033] 1) Disperse metal copper particles in the E51 epoxy resin matrix with a dispersion concentration of 20mg / ml, ultrasonically treat with ultrasonic equipment at 19.75KHz for 30 minutes, then use a magnetic stirrer at a speed of 400rpm, and stir at a heating temperature of 60°C for 1 Hours, to ensure that the particles will not agglomerate or settle.

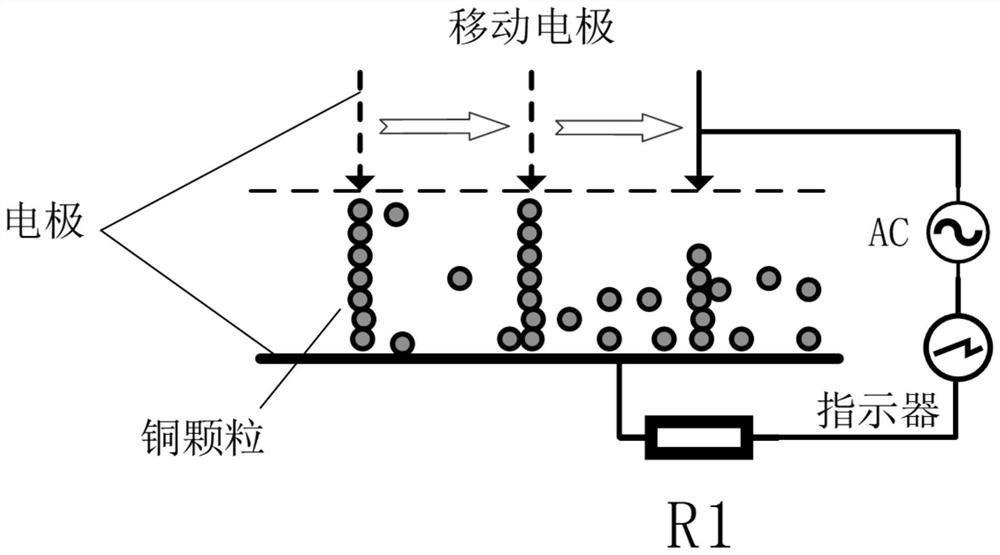

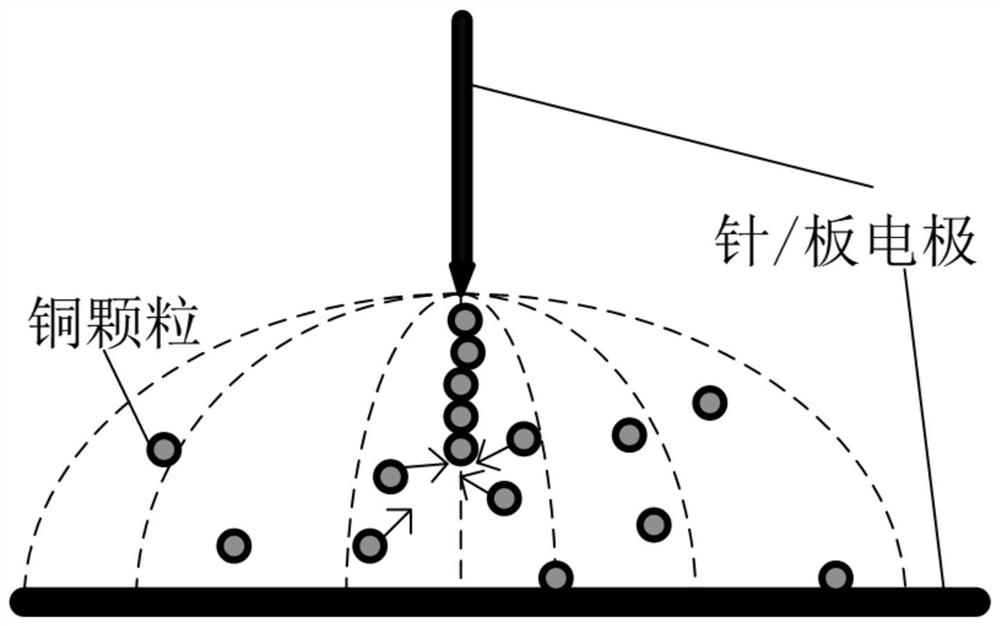

[0034] 2) After the mixed dispersion liquid in step 1) is cooled, the air bubbles of the resin are extracted with a vacuum pump, and the carbon fiber composite material is prepared using the resin. When carbon fiber is placed, an AC electric field is applied between the carbon fiber layers, and pin-plate copper electrodes with a slightly wider spacing than the layers are vertically arranged on both sides of the resin.

[0035] 3) The voltage is 50V, the frequency is 50Hz, and a protection resistor of 10kΩ is connected in series in the circuit. The dielectrophoretic assembly of the metal particles was started after the elect...

Embodiment 2

[0038] 1) Disperse the metal copper particles in the E51 epoxy resin matrix, the dispersion concentration is 50mg / ml, use an ultrasonic device to sonicate at 19.75KHz for 30 minutes, and then use a magnetic stirrer at a speed of 400rpm, and stir at a heating temperature of 60°C for 1.5 Hours, to ensure that the particles will not agglomerate or settle.

[0039] 2) After the mixed dispersion liquid in step 1) is cooled, the air bubbles of the resin are extracted with a vacuum pump, and the carbon fiber composite material is prepared using the resin. When carbon fiber is placed, an AC electric field is applied between the carbon fiber layers, and pin-plate copper electrodes with a slightly wider spacing than the layers are vertically arranged on both sides of the resin.

[0040] 3) The voltage is 50V, the frequency is 50Hz, and a protection resistor of 10kΩ is connected in series in the circuit. The dielectrophoretic assembly of the metal particles was started after the electri...

Embodiment 3

[0043] 1) Disperse the metal copper particles in the E51 epoxy resin matrix, the dispersion concentration is 80mg / ml, and use an ultrasonic device to sonicate at 19.75KHz for 45 minutes, then use a magnetic stirrer at a speed of 420rpm, and stir at a heating temperature of 80°C for 1.5 Hours, to ensure that the particles will not agglomerate or settle.

[0044]2) After the mixed dispersion liquid in step 1) is cooled, the air bubbles of the resin are extracted with a vacuum pump, and the carbon fiber composite material is prepared using the resin. When carbon fiber is placed, an AC electric field is applied between the carbon fiber layers, and pin-plate copper electrodes with a slightly wider spacing than the layers are vertically arranged on both sides of the resin.

[0045] 3) The voltage is 40V, the frequency is 60Hz, and a protection resistor of 10kΩ is connected in series in the circuit. The dielectrophoretic assembly of the metal particles was started after the electric...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com