System and method for monitoring in real time the operating state of an IGBT device

一种器件、温和的技术,应用在用直接对热敏感的电/磁性元件的温度计、单个半导体器件测试、半导体/固态器件测试/测量等方向,能够解决不适合IGBT结温在线测量等问题

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

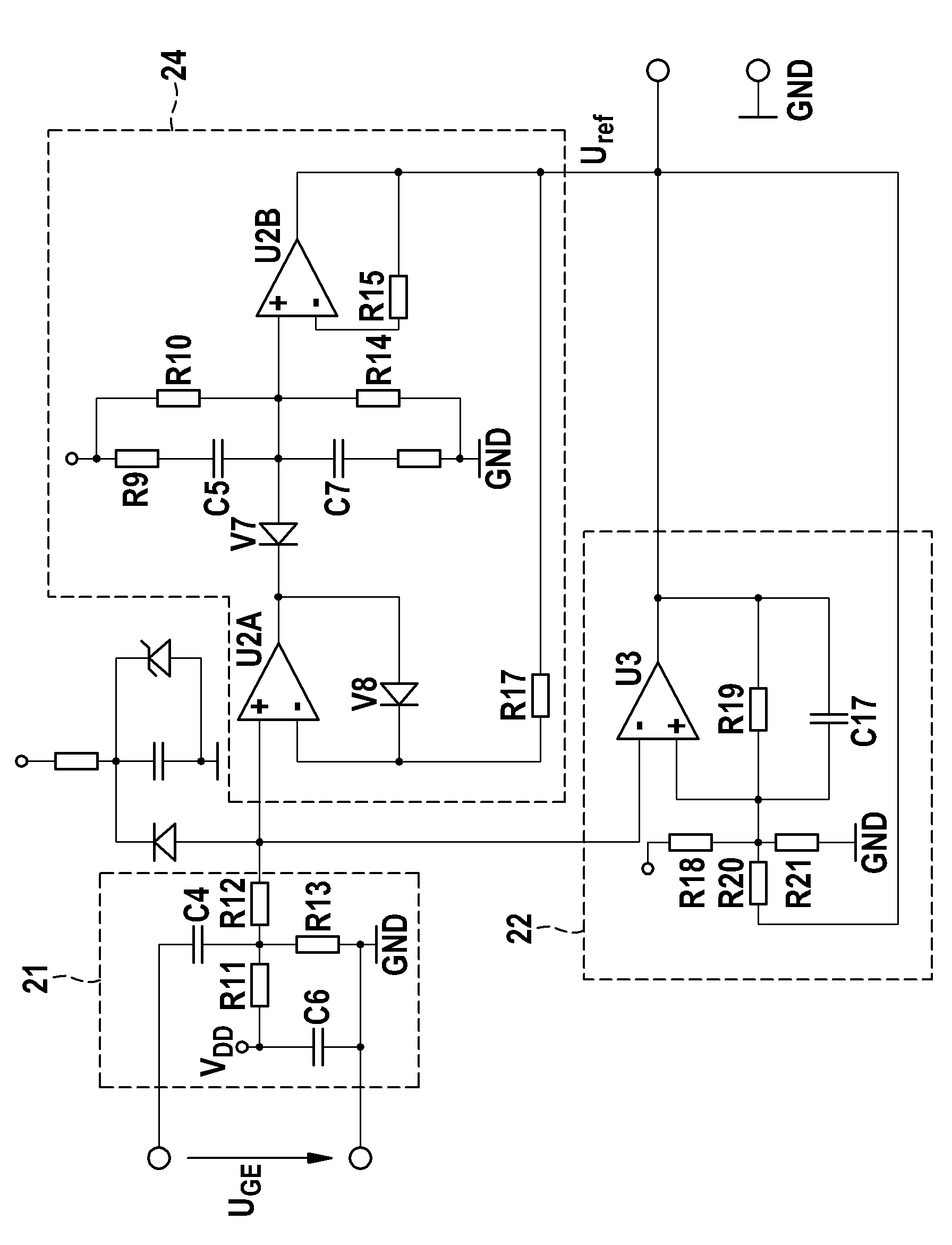

[0034] Figure 1 shows a diagram for supplying from a high supply potential at V H with a low supply potential V L A schematic diagram of the three-phase output IGBT driver module 1 generated between applied DC supply sources. The IGBT driver module 1 is controlled by a control unit 2 . The IGBT driver module 1 comprises a B6 circuit with three half-bridges 11, one for each output phase U, V, W.

[0035] Each half-bridge 11 is at high supply potential V H with a low supply potential V L A series connection between the two IGBT devices. In each of the half bridges 11, the controller terminal C of the first IGBT device 12 is connected to the high supply potential V H , while the emitter terminal E of the first IGBT device 12 is connected to the output nodes of the corresponding output phases U, V, W. The collector terminal C of the second IGBT device 13 is connected to this output node and the emitter terminal E of the first IGBT device 12, while the collector terminal C of...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com