Test system and test method for backup power supply of wind turbine pitch system

A backup power supply and wind turbine technology, applied in the field of wind power generation, can solve problems such as safety accidents, damage to wind turbine equipment, and affect the safe operation of wind turbines, so as to avoid safety accidents and meet the needs of safety testing.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

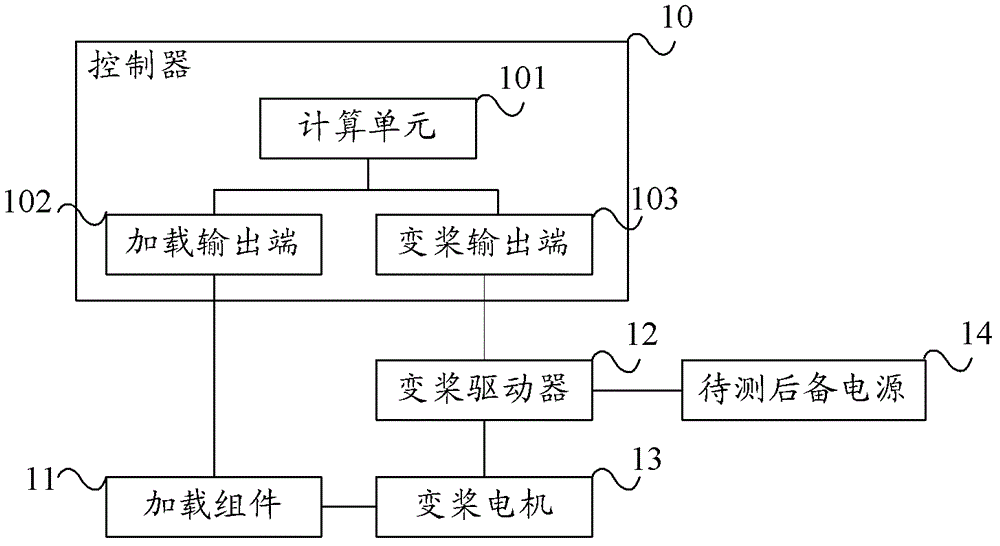

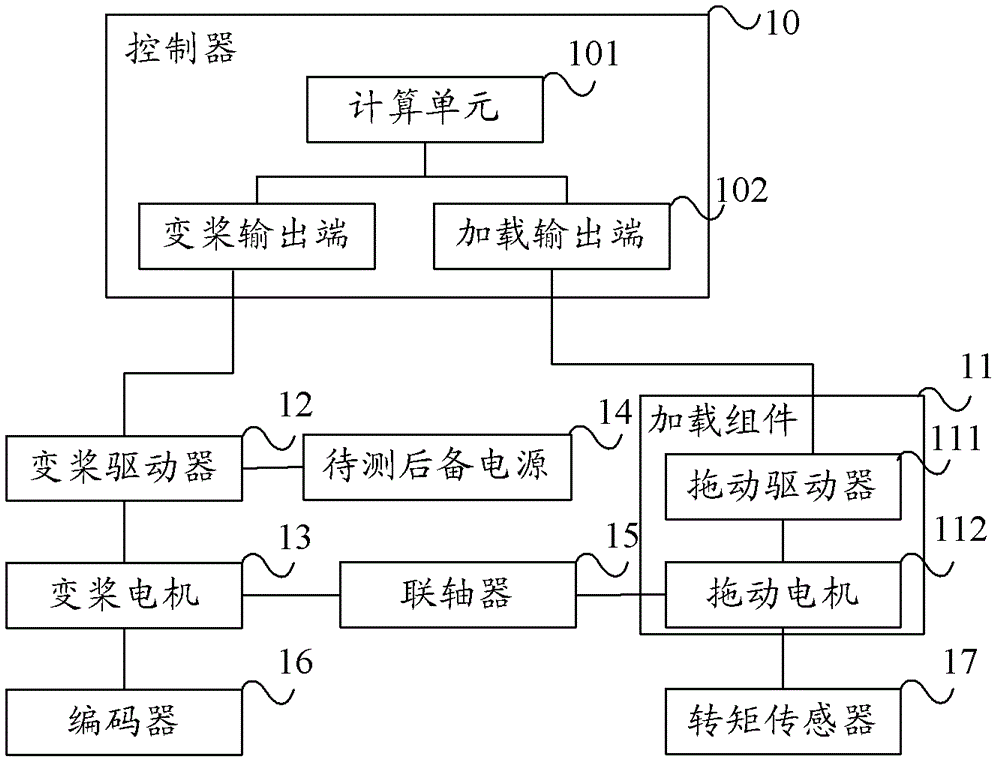

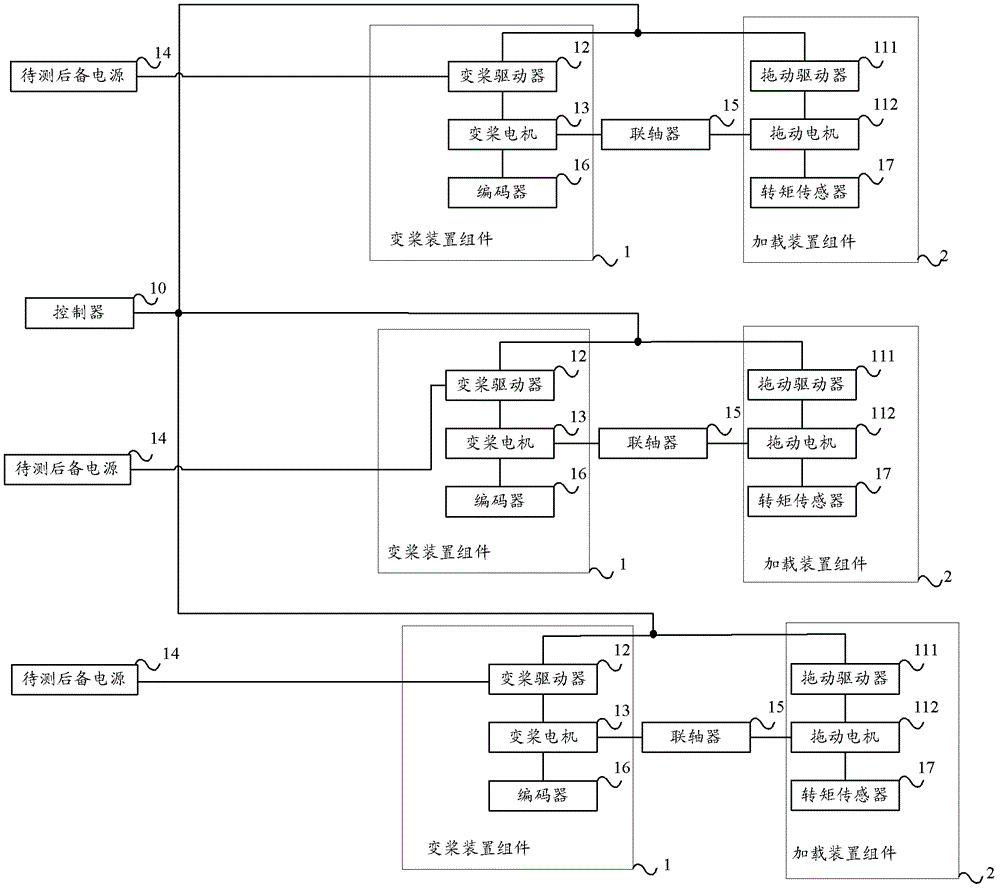

[0020] figure 1 The structural diagram of the test system for the backup power supply of the wind turbine pitch system provided by the embodiment of the present invention, as shown in figure 1 As shown, the test system includes a controller 10 , a loading assembly 11 and a pitch drive 12 .

[0021] The controller 10 includes a calculation unit 101, a load output terminal 102 and a pitch output terminal 103. The calculation unit 101 is used to calculate a given value of torque and a given value of pitch angle under each working condition according to a preset algorithm, and obtain them from The load output terminal 102 and the pitch output terminal 103 output.

[0022] The loading assembly 11 is connected to the loading output end 102 and the pitch motor 13 respectively, and is used to apply torque to the output shaft of the pitch motor 13 as a load according to a given torque value;

[0023] The pitch driver 12 is connected to the pitch output terminal 103, and is connected ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com