A method for determining the lifting and lowering load rate based on the operating data of thermal power units

A technology of raising and lowering rate and power station unit, applied in the field of soft measurement, can solve the problems of heavy workload and affecting the normal operation of the unit, and achieve the effect of low cost and accurate prediction result

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0072] The present invention will be further described below in conjunction with the accompanying drawings. The following examples are only used to illustrate the technical solutions of the present invention more clearly, and cannot be used to limit the protection scope of the present invention.

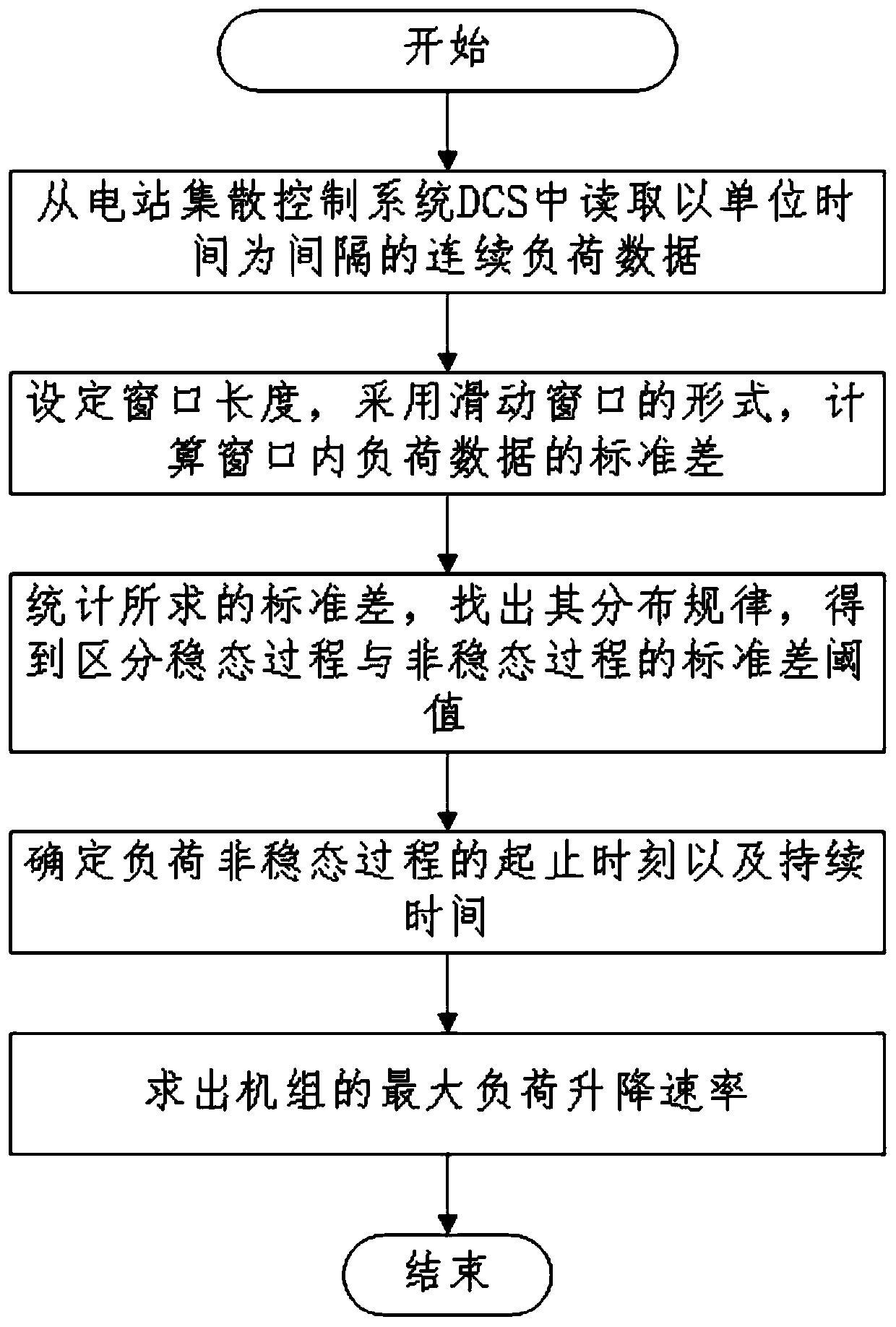

[0073] A method for determining a lifting and lowering load rate based on operating data of a thermal power unit, comprising:

[0074] Step 1: Read the continuous load data in the DCS historical database of the power station distributed control system at intervals of unit time as the total sample for calculating the maximum load lifting rate. The array composed of the load data is recorded as A, and the first-order difference is recorded as array C.

[0075] C(i)=A(i+1)-A(i)

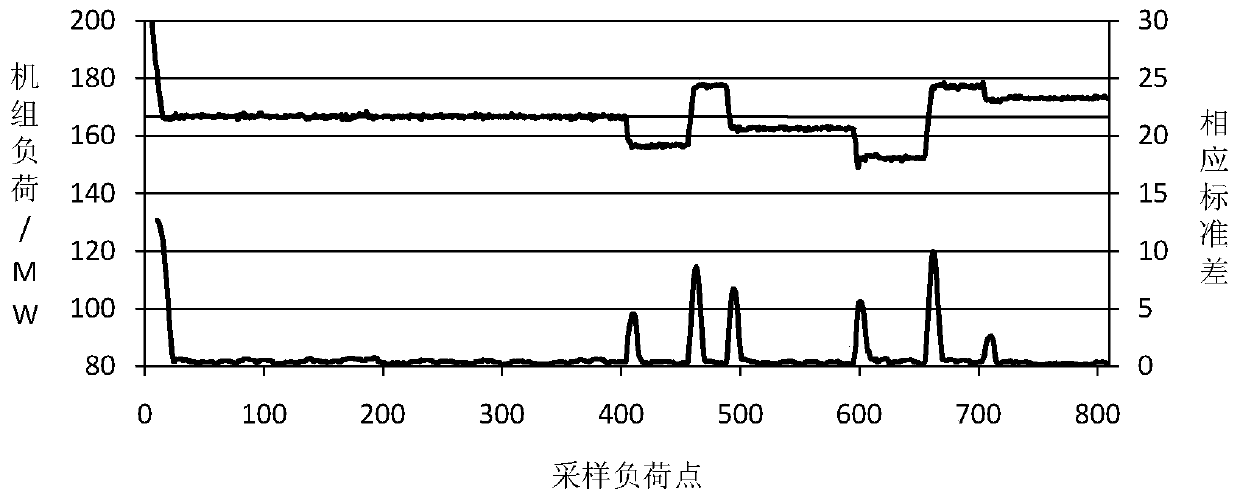

[0076] Step 2: Set the window length to 10, and calculate the standard deviation s of the load data in the window in the form of a sliding window;

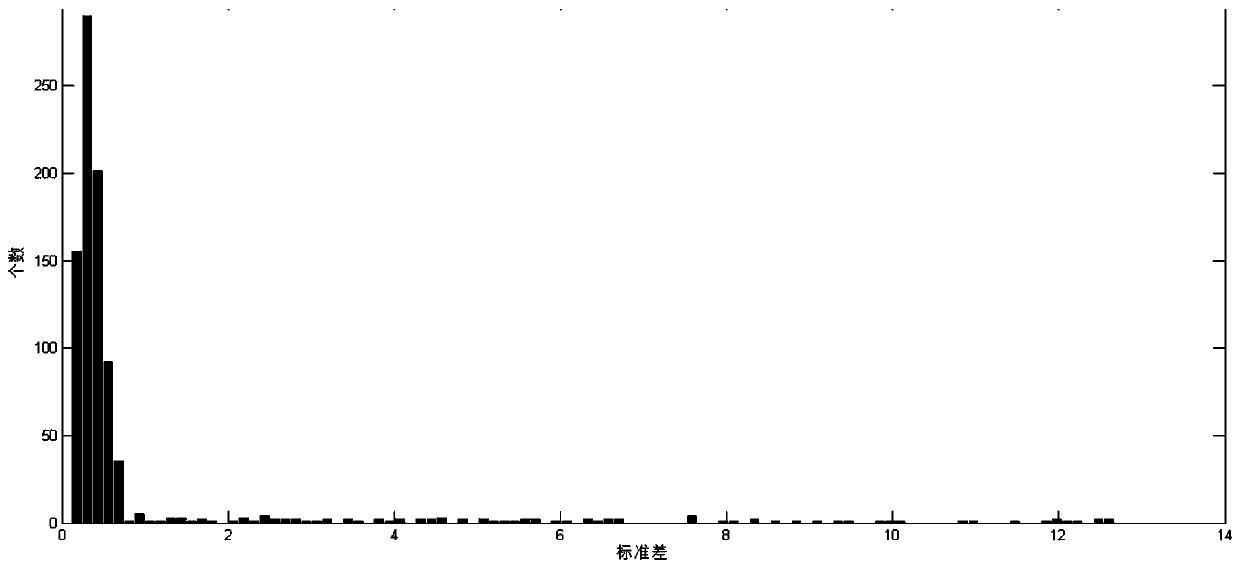

[0077] Step 3: Counting the required standard deviation, f...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com