Array substrate, manufacturing method thereof, and display device

The technology of an array substrate and its manufacturing method is applied in the field of array substrate and its manufacturing method and display device, and can solve the problems that liquid crystal displays cannot automatically adjust the display brightness according to the intensity of light.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

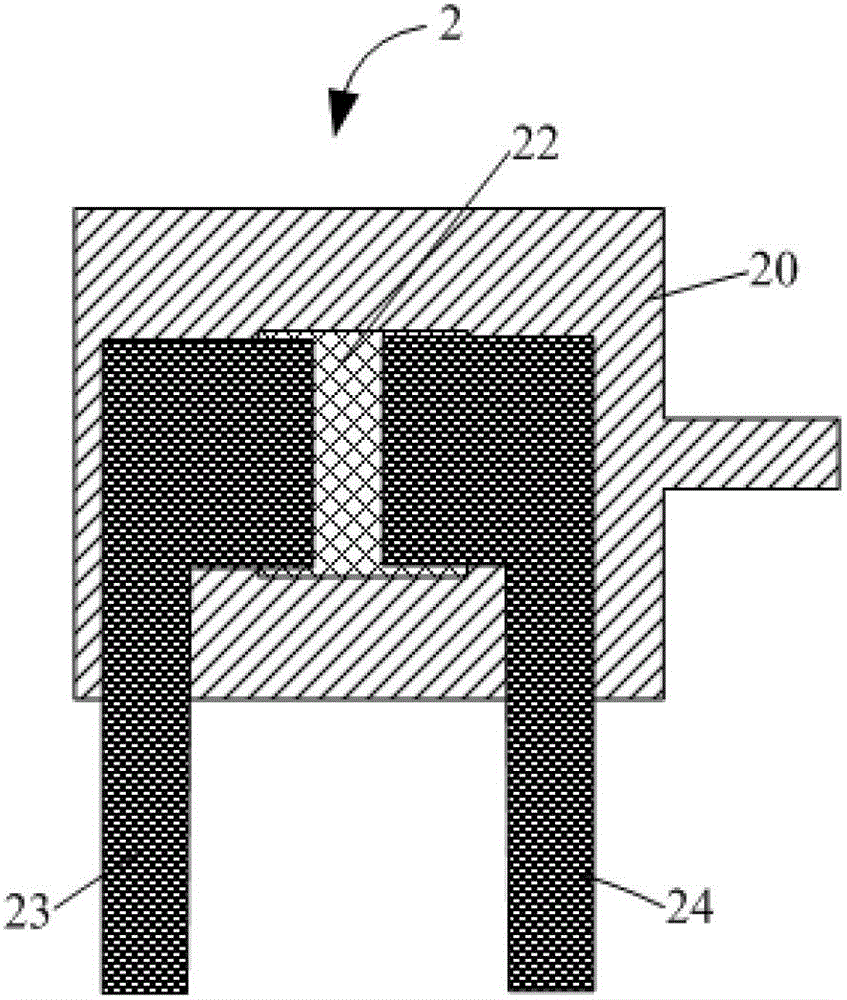

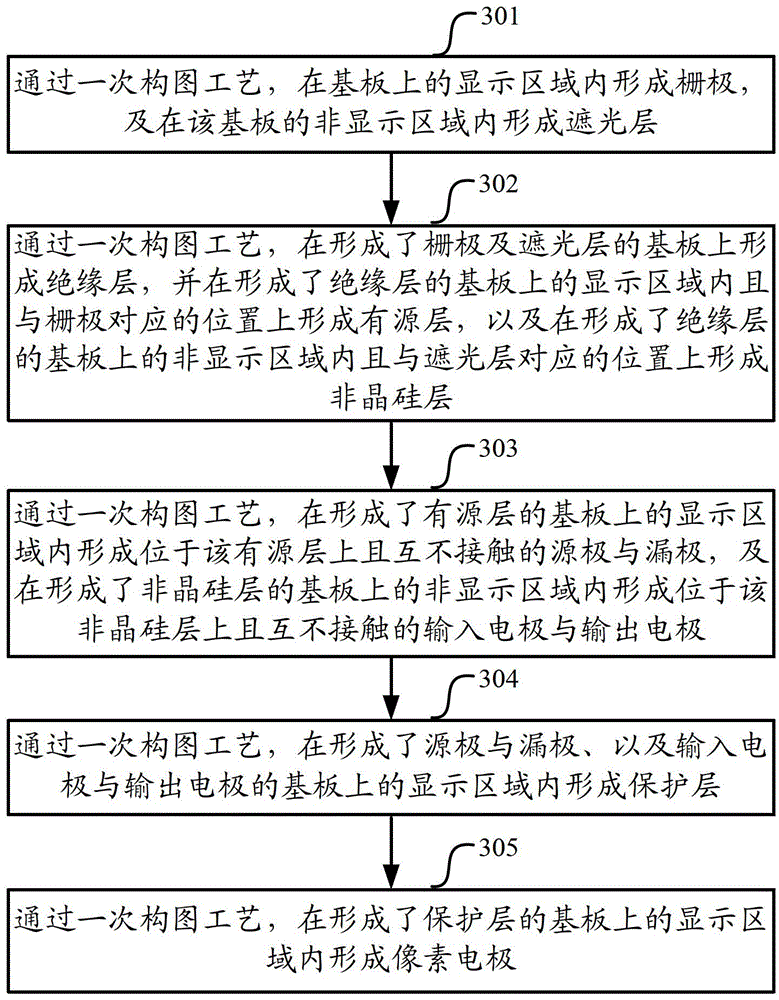

[0041] The non-display area of the array substrate in the embodiment of the present invention includes at least one photosensitive sensor, and the amorphous silicon in the amorphous silicon layer of the photosensitive sensor can generate photocarriers under the condition of light, and the external light The stronger it is, the larger the photogenerated carriers will be. Connect the output electrode of the photosensitive sensor with the photoelectric detection circuit, so that the intensity of the external light can be detected in real time through the photosensitive sensor and the photoelectric detection circuit, and according to the external light Adjust the brightness of the backlight by strength or weakness.

[0042] The embodiments of the present invention will be further described in detail below in conjunction with the accompanying drawings.

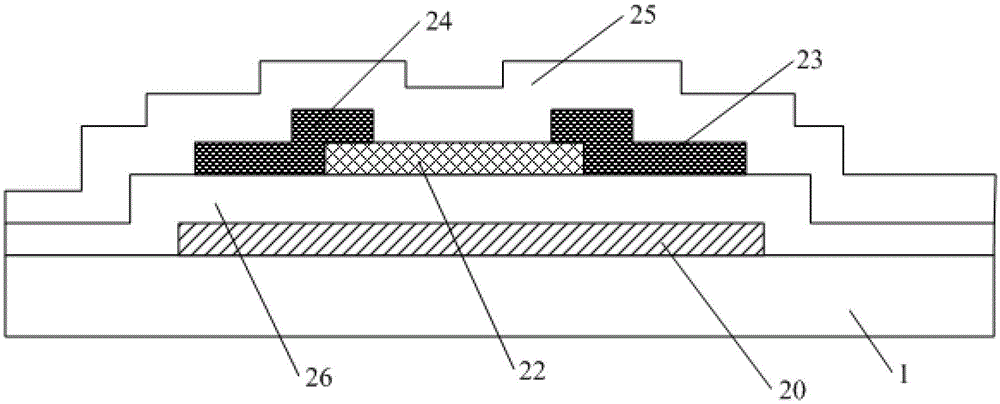

[0043] The array substrate in the embodiment of the present invention includes a display area and a non-display area, wherein t...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com