Illumination device and method for producing an illumination device

A technology for light-emitting devices and light-emitting areas, which is applied in the parts of lighting devices, semiconductor devices of light-emitting elements, lighting devices, etc., can solve problems such as loss of clarity and loss, and achieve the effect of increasing light output.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

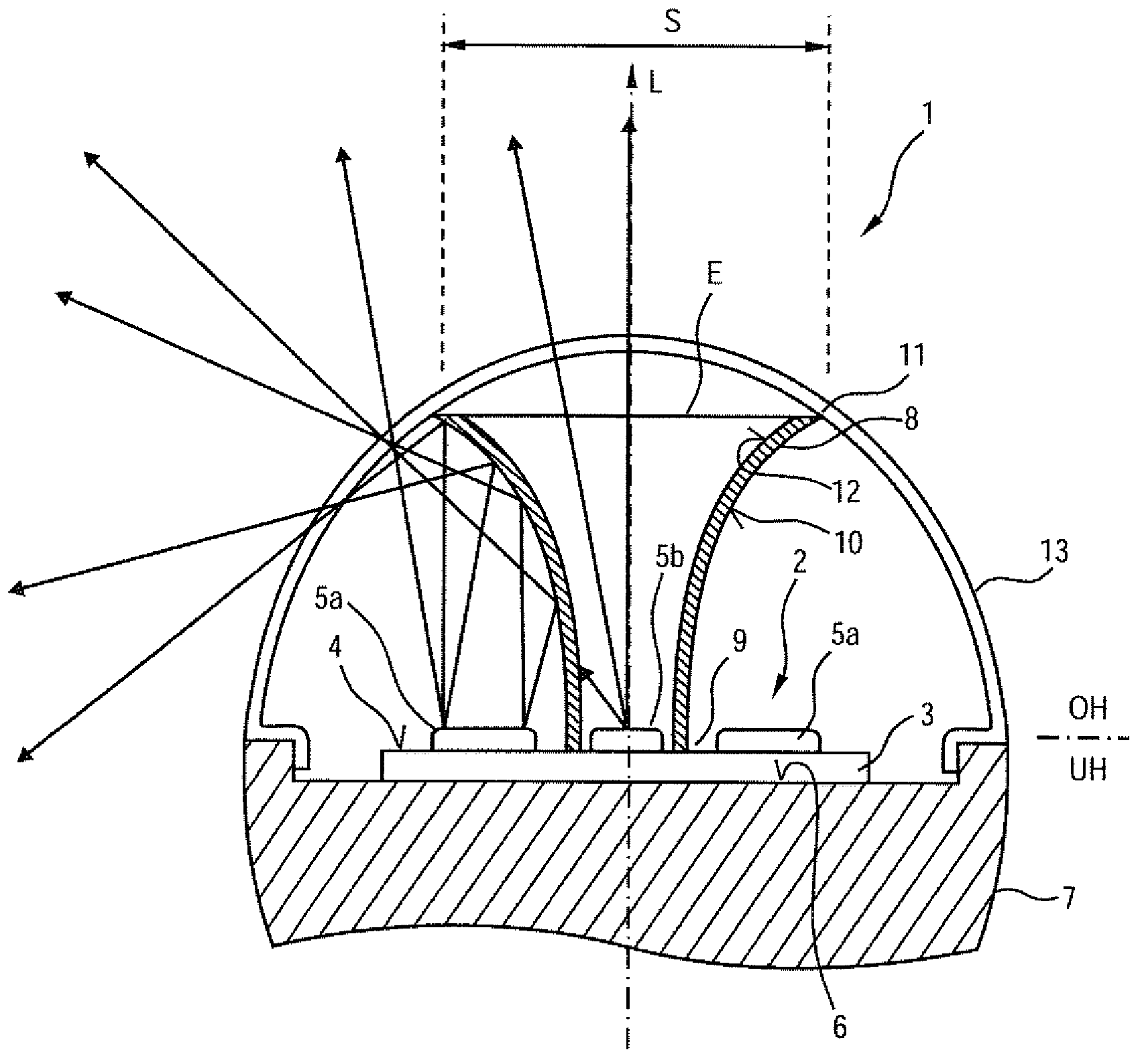

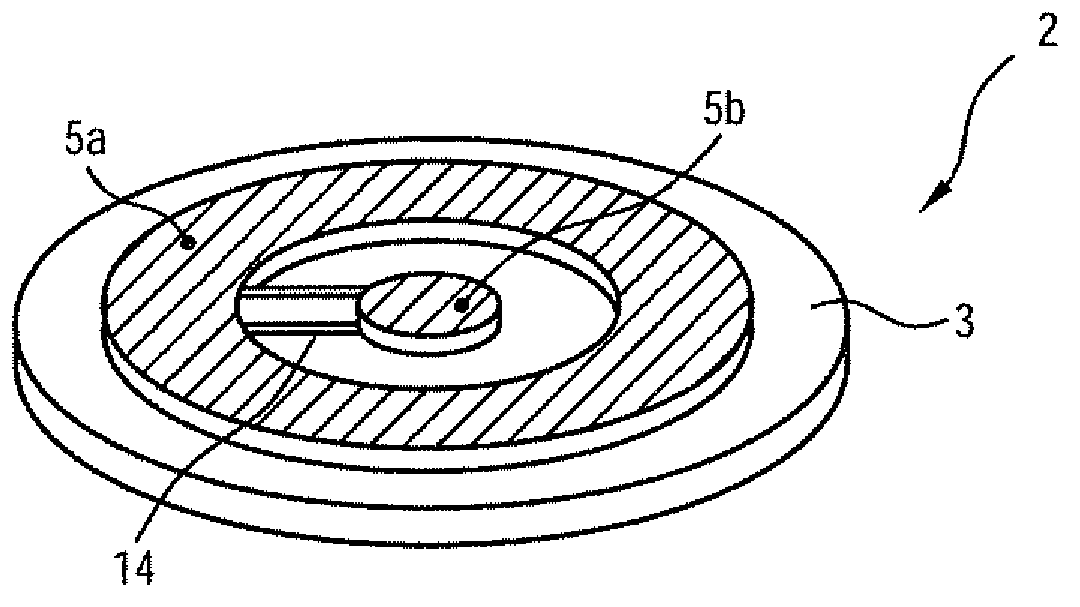

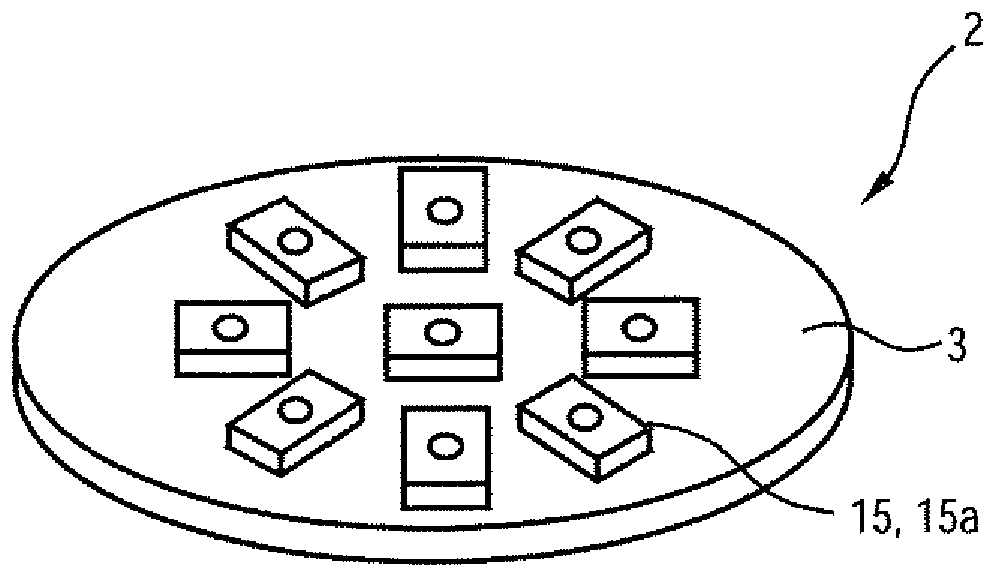

[0058] figure 1 A partial view of the front of the lighting device 1 according to the invention in the form of an incandescent retrofit lamp is shown as a sectional view in side view. The lighting device 1 is designed substantially rotationally symmetrically with respect to the longitudinal axis L. As shown in FIG. The luminous device 1 has a light-generating unit 2, wherein the light-generating unit 2 has a substrate 3, on the front side 4 of which points in the direction of the longitudinal axis L, two luminous regions 5a, 5b, ie the annular outer A light-emitting area 5a and a circular inner light-emitting area 5b. The two luminous regions 5a, 5b are separated from each other by an annular gap.

[0059] The base plate 3 is fastened with its back side 6 in a thermally conductive manner to the front side of the heat sink 7 . The rear side (not shown) of the heat sink 7 can be turned into the base for electrical and mechanical connection to a suitable lamp holder.

[0060]...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com