Gas-liquid distributor having hanging structure

A gas-liquid distributor and suspended structure technology, which is applied in chemical instruments and methods, feeding devices, chemical/physical processes, etc., can solve the problems of difficult liquid dispersion and large size of liquid clusters in the tube, and solve the problem of uneven liquid distribution. , The effect of improving the gas-liquid dispersion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

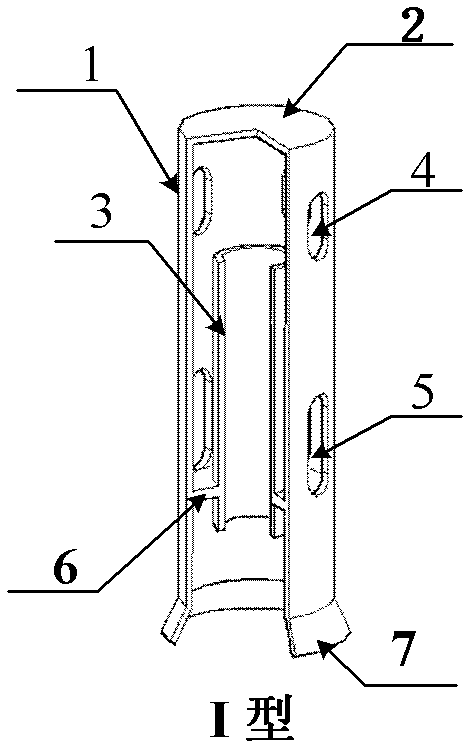

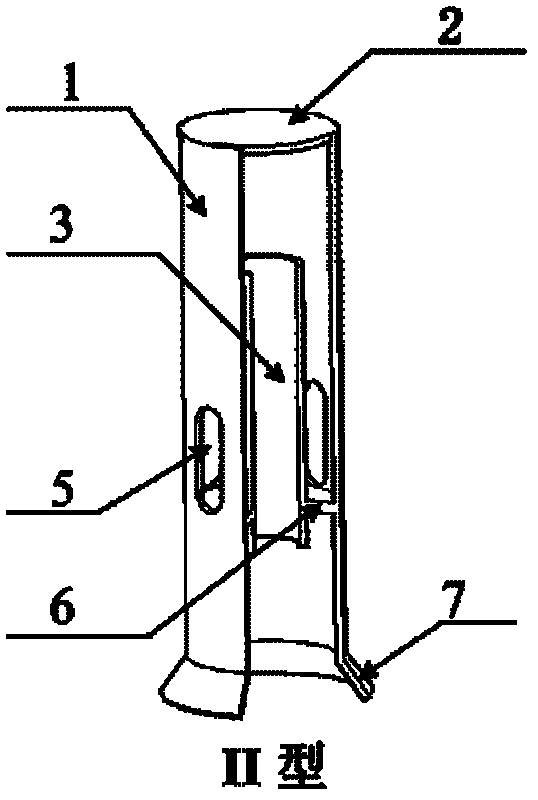

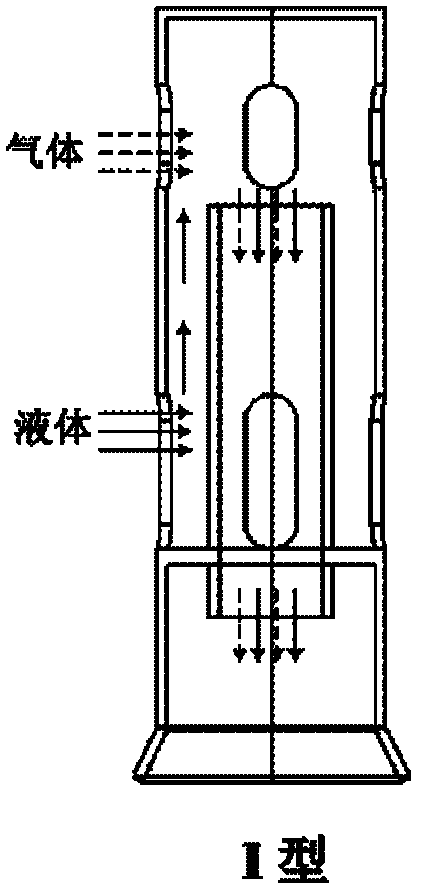

[0026] as attached figure 1 , 2 As shown, the air-liquid distributor of the present invention is composed of an outer tube 1 and an inner tube 3 suspended in the air. The inner tube 3 is installed on the inner wall of the outer tube 1 by the ring plate 6 . The outer pipe 1 is a support pipe and is installed on the distributor tray. In order to make the distribution pipe have a suction effect, the top end of the outer pipe 1 is closed by the cover plate 2 . A certain number of oval-shaped upper channels 4 and lower channels 5 are opened on the wall of the outer tube 1 as gas-liquid fluid inlets. In order to increase the dispersion radius of the liquid, the outlet end 7 of the outer tube 1 is designed as a flaring structure. According to the different requirements for the suction effect, the distributor can be designed into two structures, type I and type II. The difference between the two is that the type II structure only has a hole 5 in the lower part of the outer tube 1,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com