A high-sensitivity temperature-sensitive conductive composite fiber and its preparation method

A conductive composite fiber and high-sensitivity technology, which is applied in fiber processing, fiber chemical characteristics, rayon manufacturing, etc., can solve problems such as difficult dispersion and agglomeration of inorganic nanomaterials, so as to overcome difficult dispersion, expand the application field, and avoid low-temperature dissolution problem effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

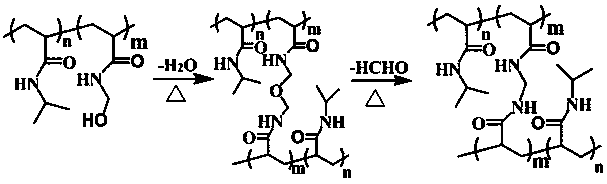

Method used

Image

Examples

Embodiment 1

[0050] 1. Preparation of P(NIPAm-co-NMA)

[0051] Add 2 g of N-isopropylacrylamide and 0.198 g of N-methylolacrylamide into a three-necked flask, vacuumize and blow nitrogen three times, then add 50 mL of deionized water, stir well, and dissolve the initiator APS in Deionized water was added to the three-neck flask through a syringe. After stirring evenly, the catalyst TEMED was added to the three-necked flask through a syringe. Under nitrogen atmosphere, react at 0°C for 4h and then react at room temperature for 20h. After the reaction is over, add the reaction solution into a dialysis bag and dialyze in deionized water at room temperature for 72 hours, change the deionized water every 12 hours to remove unreacted monomers, and finally freeze-dry the product to obtain P(NIPAm-co-NMA) .

[0052] 2. Preparation of P(NIPAm-co-NMA) / Ag composite fiber

[0053] Dissolve 1 g of the prepared P(NIPAm-co-NMA) in 9 g of DMAc / THF (volume ratio 5:4) mixed solvent to form a uniform sol...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com