Preparing method for conductive polymer nanoparticle composite TiO2-base thermoelectric material

A conductive polymer and nanoparticle technology, applied in the manufacture/processing of thermoelectric devices, nanotechnology, etc., can solve problems such as reducing thermal conductivity, and achieve the effect of reducing thermal conductivity, improving thermoelectric performance, and low reaction temperature

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

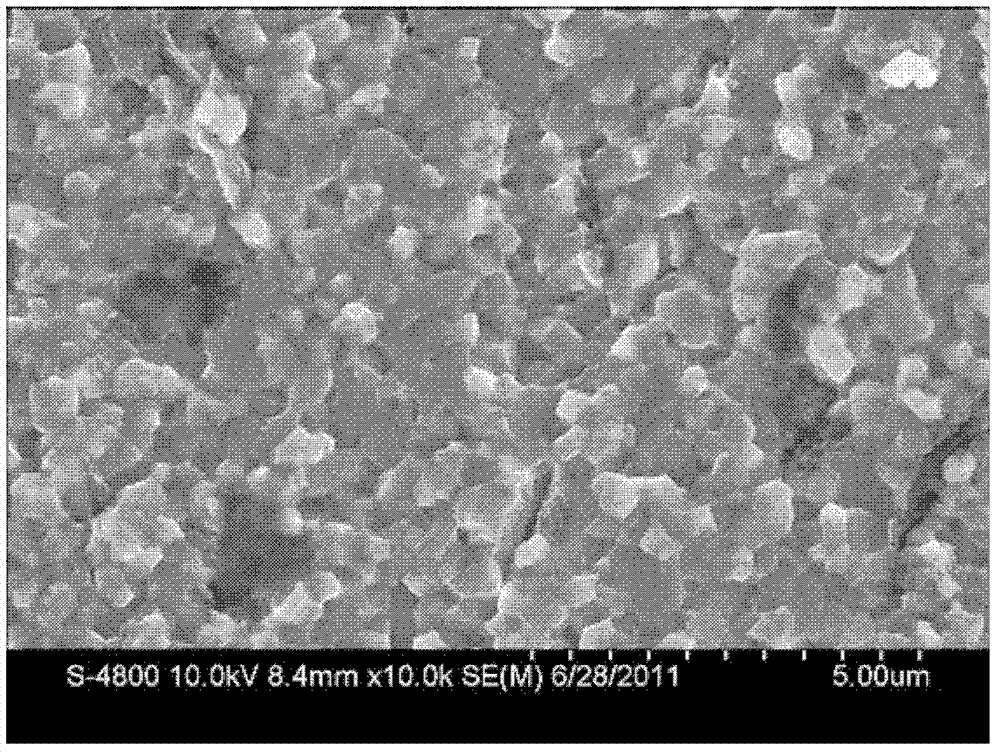

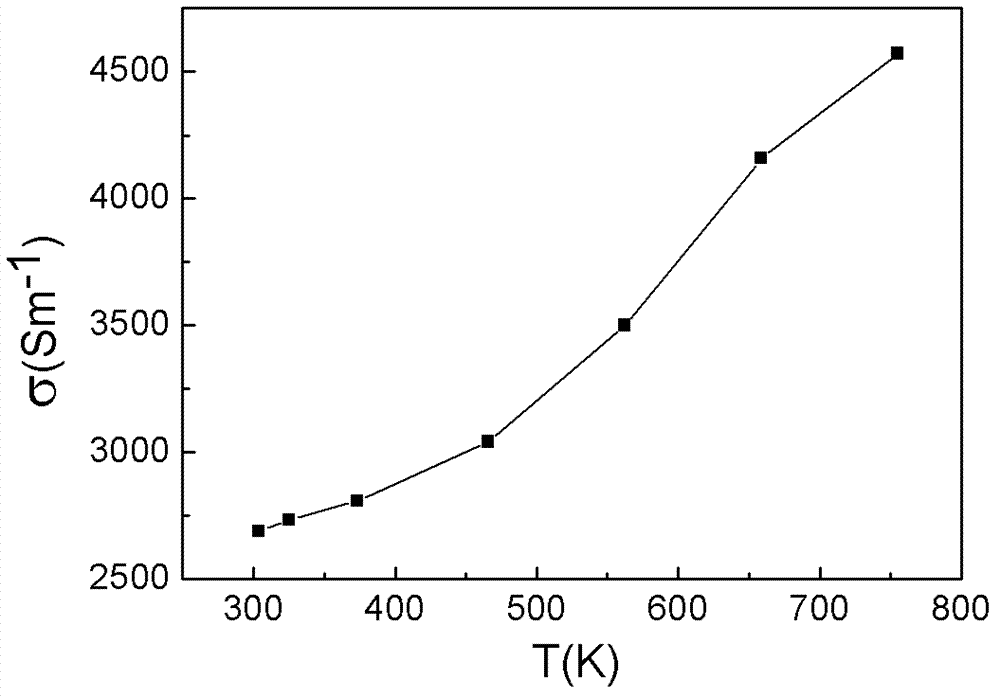

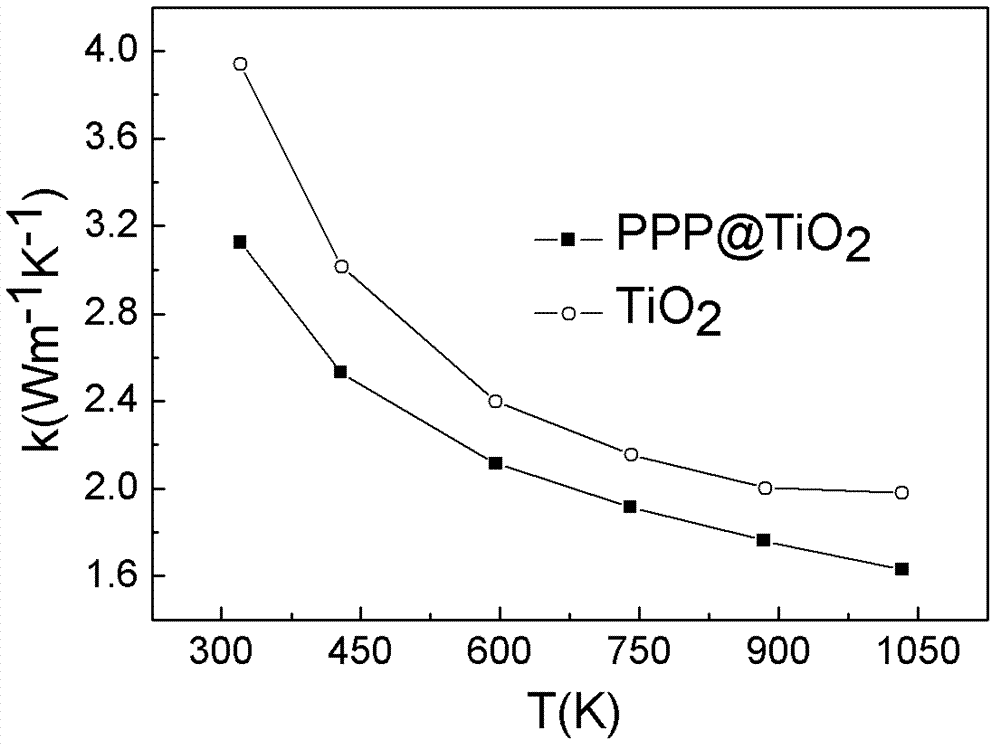

[0023] First, mix 34ml of tetrabutyl titanate with 160ml of absolute ethanol and put it in a separatory funnel. Add 90ml of glacial acetic acid and 247.5ml of ethanol with a volume fraction of 95% to the ferric nitrate solution containing 0.003mol of iron, and mix thoroughly for 30 minutes. Then slowly drop the tetrabutyl titanate solution into the ferric nitrate solution, and continue stirring for 1 hour after the dropping to form a uniform and transparent sol. Add 0.0040 g of poly-p-phenylene nanoparticles to the sol, place it at room temperature after ultrasonication for 2 hours until a gel is formed, and dry the gel at 80° C. and grind it into powder. The powder was calcined at high temperature in a muffle furnace for 2 hours, and the bulk thermoelectric material was prepared by spark plasma sintering. The sintering conditions were: the sintering atmosphere was vacuum, the pressure was 60 MPa, the temperature was 750 ° C, and the holding time was 8 minutes. The obtained t...

Embodiment 2

[0025] First, mix 51ml of tetrabutyl titanate with 240ml of absolute ethanol and put it in a separatory funnel. Add 45ml of glacial acetic acid and 247.5ml of ethanol with a volume fraction of 95% to the ferric nitrate solution containing 0.0015mol of iron, and mix thoroughly for 30 minutes. Then slowly drop the tetrabutyl titanate solution into the ferric nitrate solution, and continue stirring for 1 hour after the dropping to form a uniform and transparent sol. Add 0.0016g of poly-p-phenylene nanoparticles to the sol, place it at room temperature after ultrasonication for 2 hours until a gel is formed, and dry the gel at 80°C and grind it into powder. The powder was calcined at high temperature in a muffle furnace for 2 hours, and the bulk thermoelectric material was prepared by spark plasma sintering. The sintering conditions were: the sintering atmosphere was vacuum, the pressure was 30 MPa, the temperature was 850°C, and the holding time was 5 minutes. The resulting comp...

Embodiment 3

[0027] First, mix 68ml of tetrabutyl titanate with 360ml of absolute ethanol and put it in a separatory funnel. Add 90ml of glacial acetic acid and 247.5ml of ethanol with a volume fraction of 95% to the ferric nitrate solution containing 0.02mol of iron, and mix thoroughly for 30 minutes. Then slowly drop the tetrabutyl titanate solution into the ferric nitrate solution, and continue stirring for 1 hour after the dropping to form a uniform and transparent sol. Add 0.0032g of poly-p-phenylene nanoparticles to the sol, place it at room temperature after ultrasonication for 2 hours until a gel is formed, and dry the gel at 80°C and grind it into powder. The powder was calcined at high temperature in a muffle furnace for 2 hours, and the bulk thermoelectric material was prepared by spark plasma sintering. The sintering conditions were: the sintering atmosphere was vacuum, the pressure was 50 MPa, the temperature was 800 ° C, and the holding time was 6 minutes. The resulting comp...

PUM

| Property | Measurement | Unit |

|---|---|---|

| electrical conductivity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com