Die with inserting mechanism

A plug-in mechanism and mold technology, used in forming tools, manufacturing tools, metal processing equipment, etc., can solve the problems of economic loss, unstable positioning, scrapped molds, etc., to prolong the service life, improve the qualification rate, and have a simple structure. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

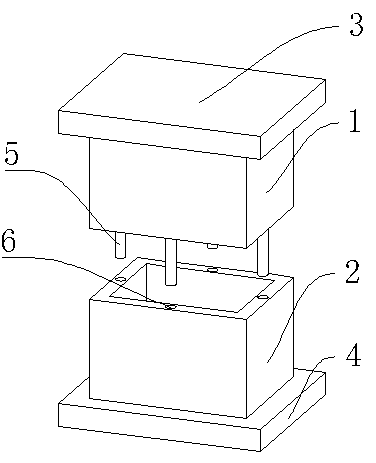

[0014] like figure 1 The shown mold with a plug-in mechanism includes an upper template 1 and a lower template 2; the upper template 1 and the lower template 2 are respectively provided with an upper fixing plate 3 and a lower fixing plate 4; The top of each side is provided with a groove 6; the bottom of the four sides of the upper template 1 is provided with bumps 5; the grooves 6 are connected with the bumps 5 to form a plug-in mechanism.

[0015] Wherein, the groove 6 and the bump 5 are both cylindrical; the cross-section of the upper fixing plate 3 and the lower fixing plate 4 is a rectangle; the depth of the groove 6 is 1 / 2 of the height of the lower template 2; The height of the bump 5 is the same as the depth of the groove 6 .

[0016] The present invention has a simple structure, accurate positioning and strong wear resistance of a mold with a plug-in mechanism; since the lower mold plate of the present invention is provided with grooves, and the upper mold plate is ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com