Method for casting low speed diesel engine cylinder cap for large cylinder diameter boat

A cylinder head and large cylinder diameter technology, which is applied to casting molding equipment, casting molds, casting mold components, etc., can solve the problems of high cost of resin sand, large gas generation, and poor cylinder head feeding effect. The effect of reducing production cost, shortening production cycle and stabilizing casting production

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0026] The specific parameters of cylinder head castings for 7RT-flex82T large-bore marine low-speed diesel engine with a cylinder diameter of 82cm are as follows:

[0027] Casting material: G17CrMo5-5

[0028] Maximum dimensions of castings: φ1520mm×542mm

[0029] Maximum wall thickness of casting: 400mm

[0030] Minimum casting wall thickness: 210mm

[0031] Casting blank weight: 5400kg

[0032] The specific casting process of this cylinder head is as follows:

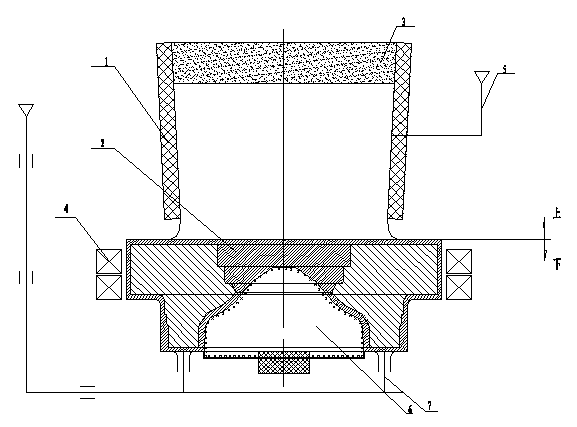

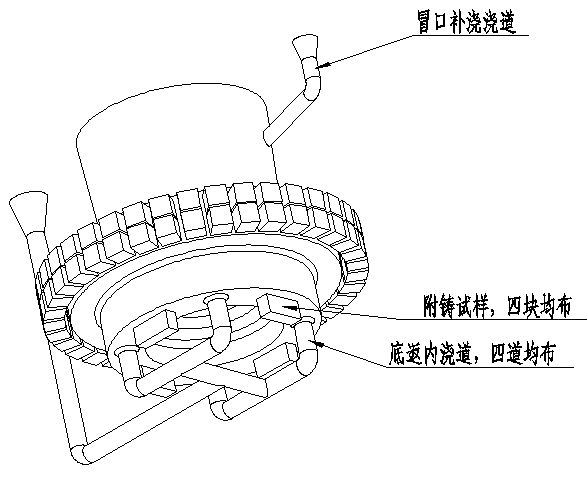

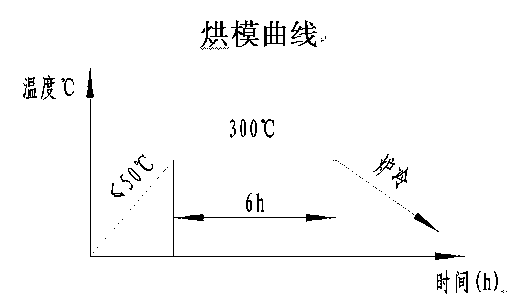

[0033] (1) Casting process design. According to the principle of sequential solidification, with the large plane of the cylinder head as the parting surface, a circular riser 1 is placed in the middle of the large plane, and a subsidy 2 is set under the riser 1. This subsidy can ensure that there are enough feeding channels to make the The molten steel can be fed to the largest hot spot of the casting body. Compared with the scheme of symmetrically placing two risers on the annular surface, this scheme is more ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com