Device and method for automatically sealing and opening furnace cover of smelting furnace for magnesium liquid positive pressure transfer

An automatic sealing and smelting furnace technology, which is applied in the direction of furnaces, crucible furnaces, furnace components, etc., can solve the problems of high labor intensity, hidden safety hazards, and low automation, and achieve good sealing and transmission functions, good heat insulation and heat preservation The effect of characteristics and simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

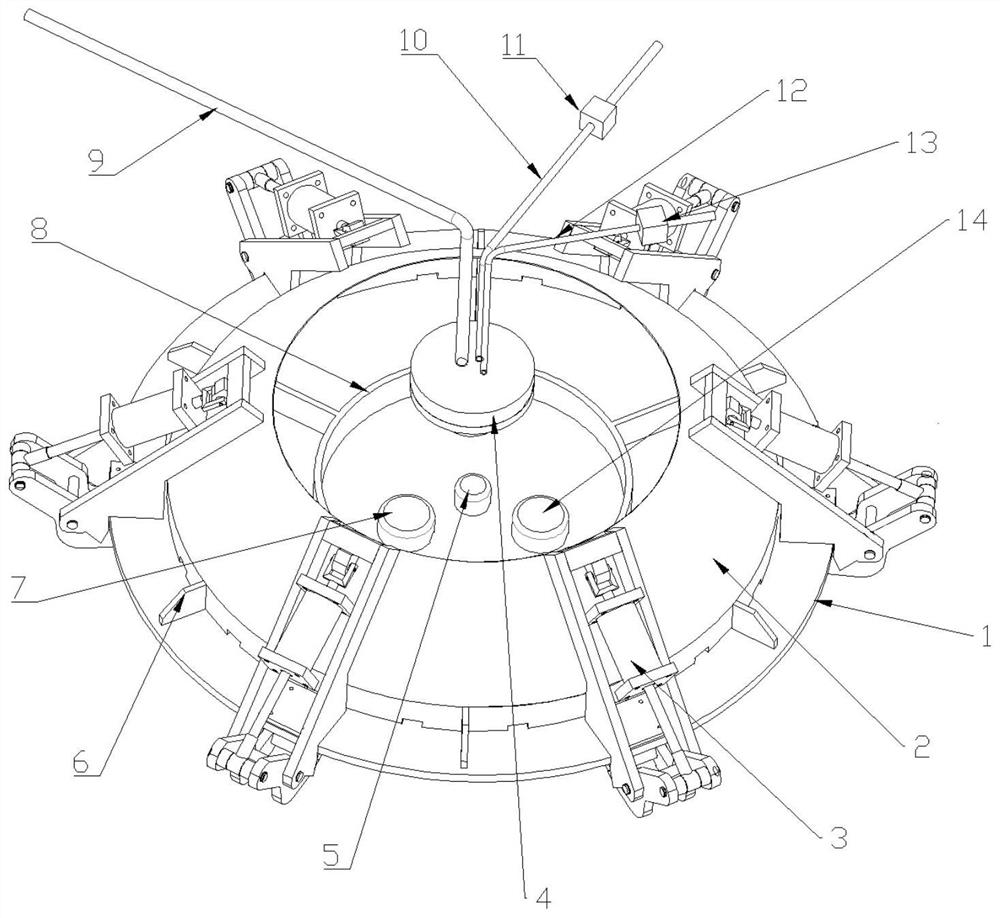

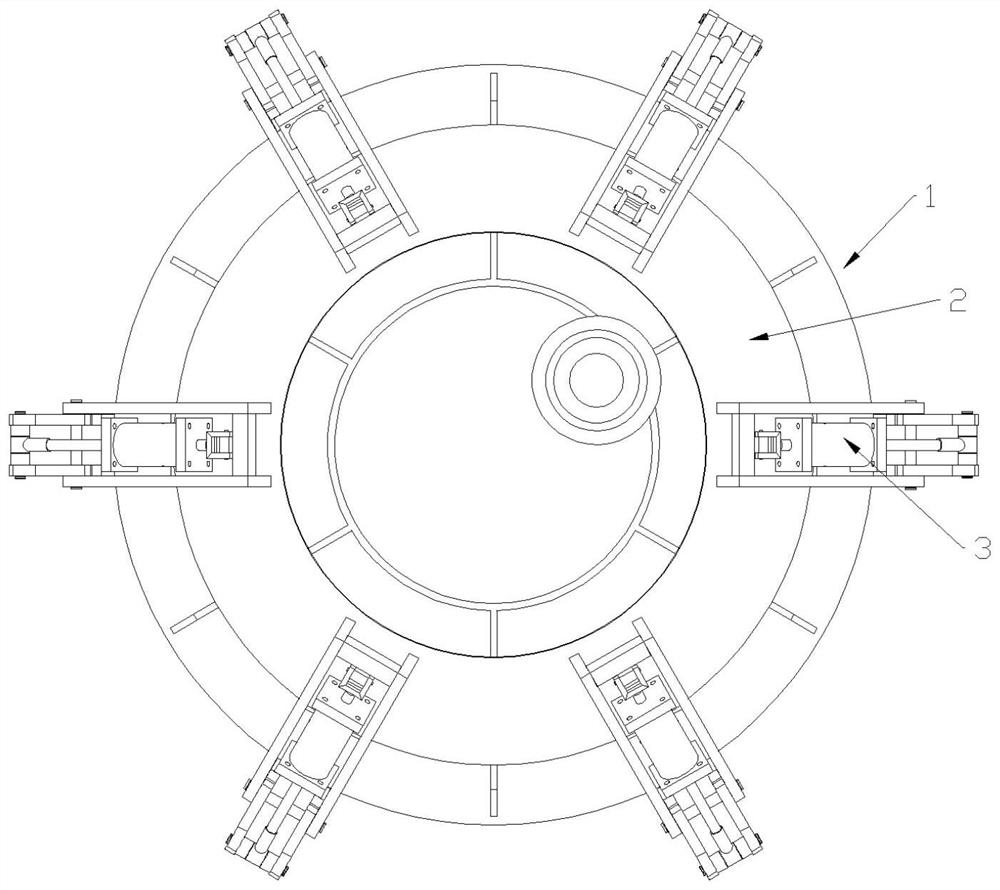

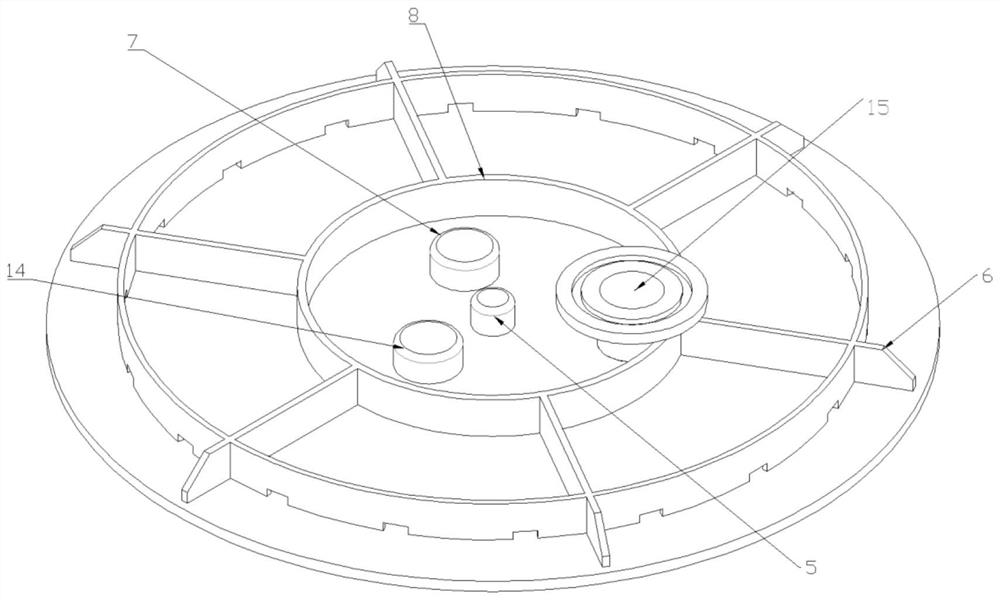

[0051] The structure of a device for automatic sealing and opening of a smelting furnace cover used in positive pressure transfer of molten magnesium used in the embodiment of the present invention is as follows: figure 1 As shown, the top view is figure 2 , the structure diagram of the furnace cover is image 3 , Schematic diagram of the structure of the grasping device, see Figure 4 .

[0052] In an embodiment of the present invention, a device for automatically sealing and opening the furnace cover of a smelting furnace for positive pressure transfer of magnesium liquid includes a furnace cover, a grasping device 3, a liquid guide integration device 4 and a control system. The furnace cover includes a bottom plate 1 and a heat preservation cover 2. The bottom plate 1 is a circular steel plate. On the eccentric position of the bottom plate of the furnace cover, a liquid guide flange 14, a pressure gauge 7, a safety valve 14 and a temperature measuring device 5 are arrang...

Embodiment 2

[0068] A device for automatically sealing and opening the furnace cover of a smelting furnace for positive pressure transfer of magnesium liquid, including a furnace cover, a liquid guiding flange arranged on the furnace cover, a pressure gauge, a safety valve and a temperature measuring device; it also includes a plurality of grasping devices , Integrated liquid guiding device and control system;

[0069] The furnace cover includes a bottom plate and a heat preservation cover. The heat preservation cover is funnel-shaped. The material of the heat preservation cover is high-temperature resistant stainless steel, and the thickness is preferably 5-10mm. Circular reinforcing ribs and multiple strip-shaped reinforcing ribs evenly distributed on the outer periphery of the circular reinforcing ribs prevent the furnace cover from being deformed at high temperature; the liquid guiding flange, pressure gauge and safety valve are all arranged in the area of the circular reinforcing rib...

Embodiment 3

[0090] The device for automatically sealing and opening the furnace cover of a smelting furnace for positive pressure transfer of molten magnesium in this embodiment is different from that of Embodiment 1 in that: when the diameter of the furnace cover is 4m, the thickness of the cover is 60mm, and the number of grasping devices is 20 indivual.

[0091] In the grasping device that present embodiment adopts, adopt pneumatic expansion and contraction.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com