Automatic compensation system for electrode tip of welding manipulator

A welding manipulator and automatic compensation technology, applied in the direction of electrode characteristics, etc., can solve the problems of failing to meet quality requirements, affecting product quality, affecting welding quality, etc., and achieve the effect of preventing data loss and safe and reliable operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] Below in conjunction with specific embodiment, the present invention is further described:

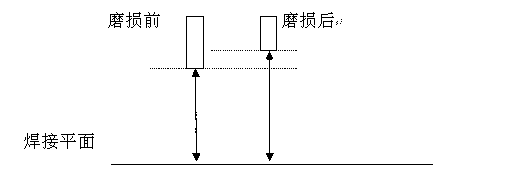

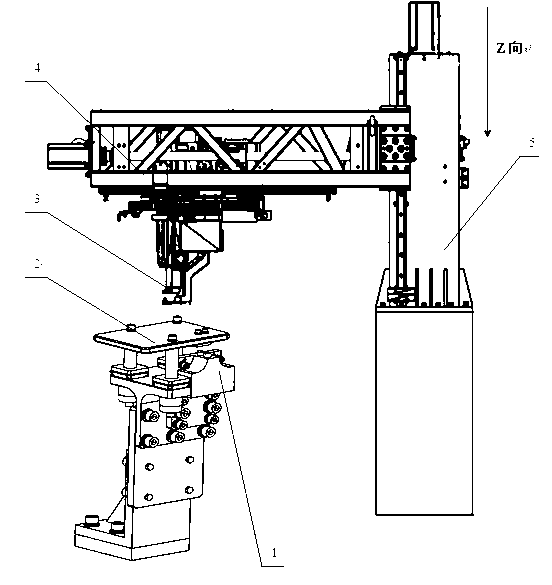

[0023] see figure 1 and figure 2 , automatic compensation system for electrode head of welding manipulator, including beam 4, column 5, welding manipulator and welding platform, compensation plane 2 and detection switch 1 are also installed on the welding platform, detection switch 1 is connected with automatic lifting control system of welding manipulator, The height of the welding manipulator and the upper electrode head 3 installed on it is automatically controlled by the signal of the detection switch 1, wherein the automatic lifting control system of the welding manipulator includes: a current detection and analysis module, an alarm device and an automatic compensation system, wherein The described automatic compensation system has:

[0024] The receiving control switch for receiving the alarm signal receives the signal from the alarm device;

[0025] A position detecti...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com