Damping device with controllable hydraulic pressure

A damping device and hydraulic technology, applied in transportation and packaging, conveyors, earthwork drilling and mining, etc., can solve the problems of affecting the service life of conveyor belts and belt buckles, increasing equipment maintenance costs, and increasing wear and tear of conveyor belts and belt buckles , to achieve the effect of improving negative effects, avoiding wear and ensuring normal shutdown

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

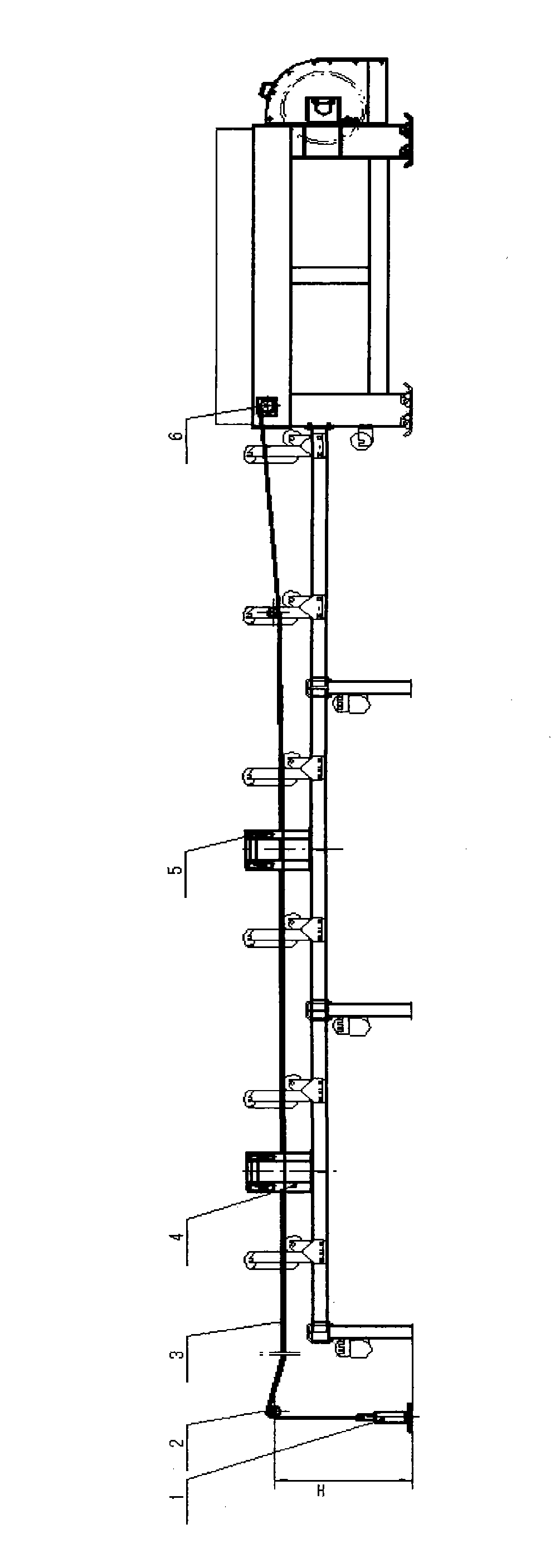

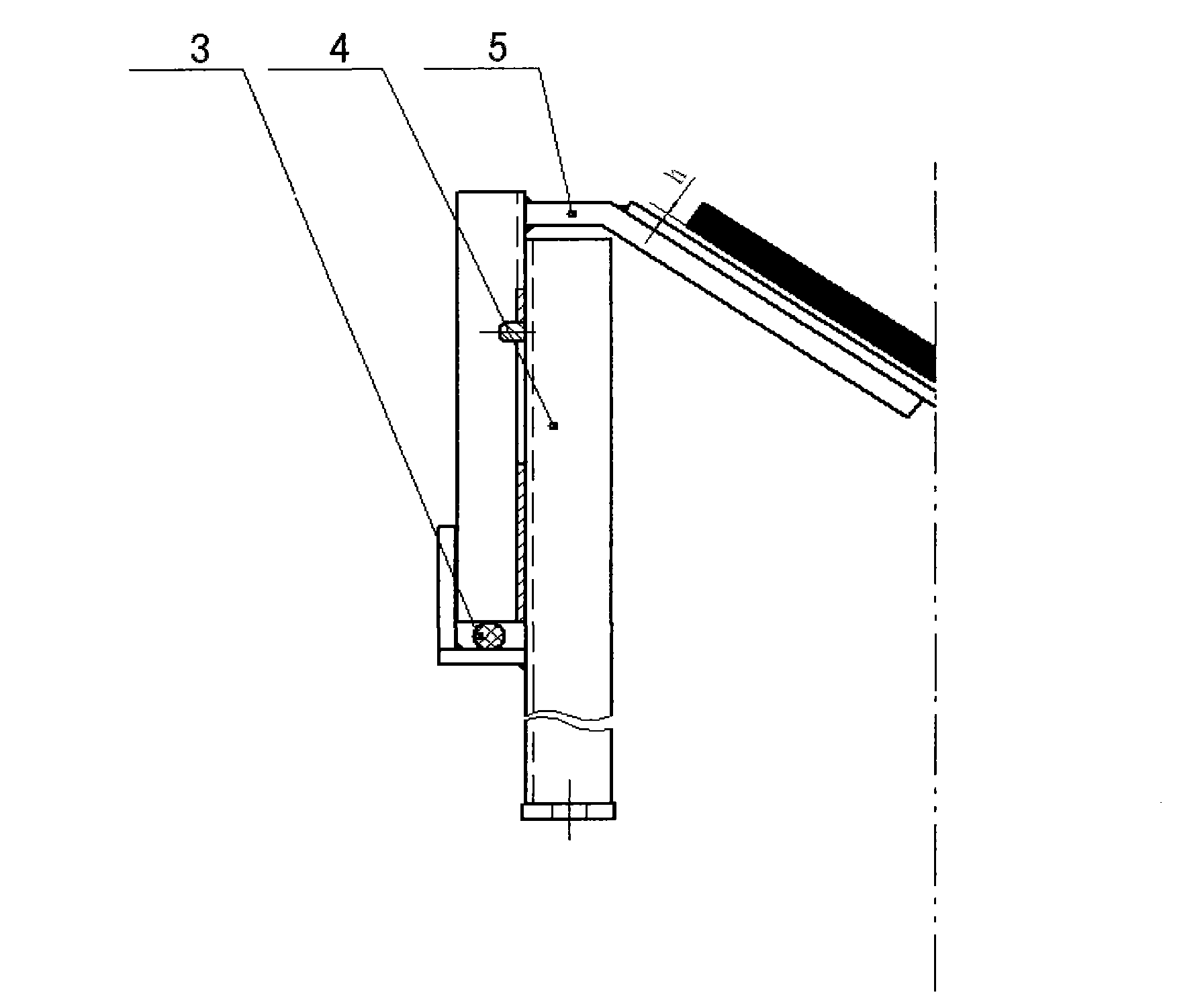

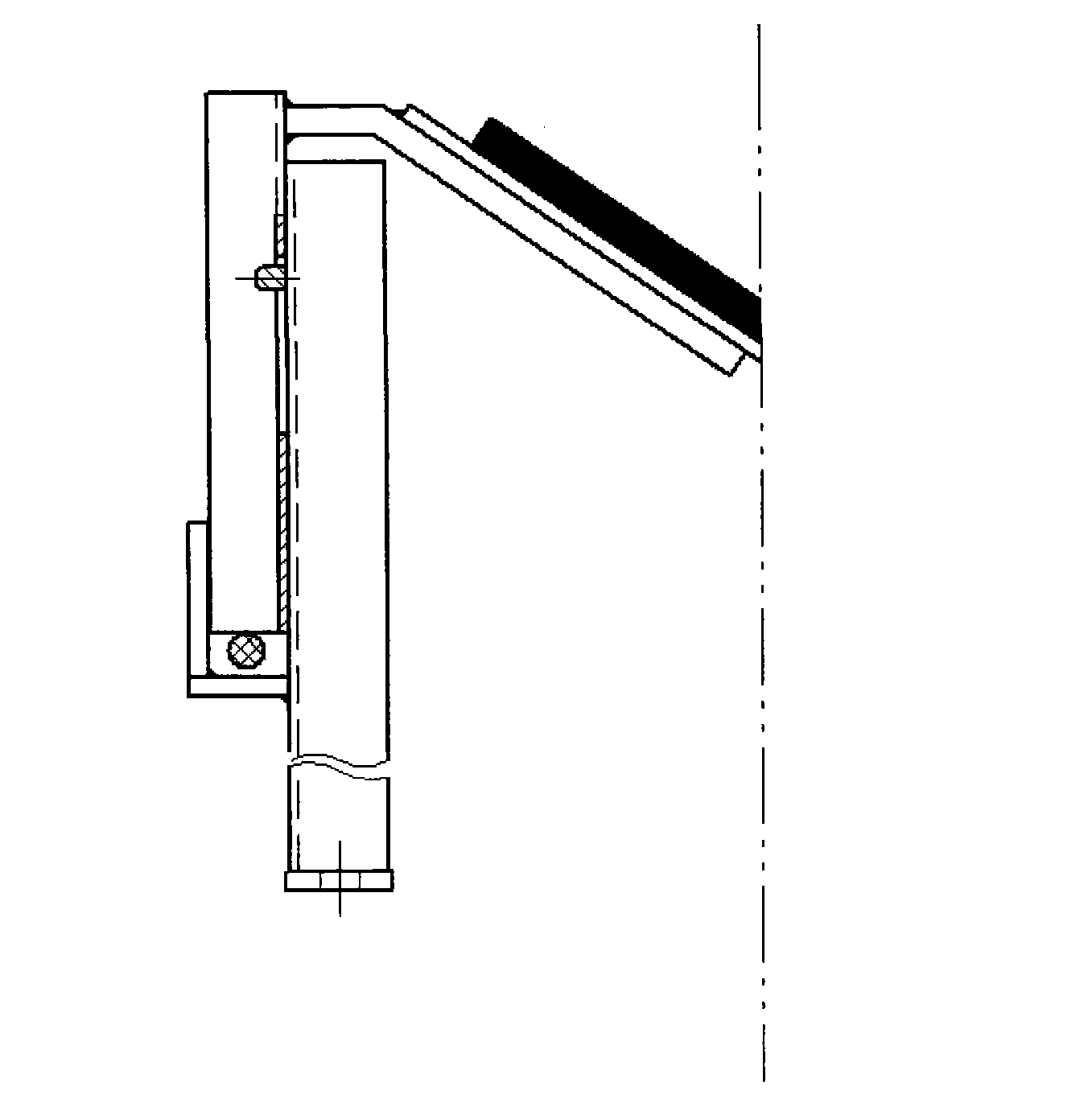

[0012] The hydraulic controllable damping device refers to: the hydraulic cylinder fixed on the foundation adjusts the height of the damping device by controlling the slack of the wire rope, so that it can control the damping force generated by the damping device.

[0013] Specific operation process:

[0014] When the trough retractable belt conveyor is in normal operation, it is not necessary to adjust the hydraulic cylinder 1, that is, to keep the wire rope 3 in a slack state, so that the damping plate assembly 5 is separated from the conveyor belt. When the machine stops, the hydraulic cylinder 1 is supplied with liquid by the pump station, the piston rod is lowered, and the steel wire rope 3 is tightened to make the damping plate assembly 5 rise, which is in close contact with the conveyor belt, and the damping force generated can offset the sliding force of the material, ensuring The normal shutdown of the conveyor also makes the life of the conveyor belt and belt buckle ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com