Method and device for detecting balance point of balance weight of portal crane

A technology of counterweight balance and point detection, applied in cranes, transportation and packaging, load hanging components, etc., can solve the problems of heavy workload, heavy boom, severe vibration of the whole machine, etc., to achieve easy operation, eliminate safety The effect of hidden danger and error avoidance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

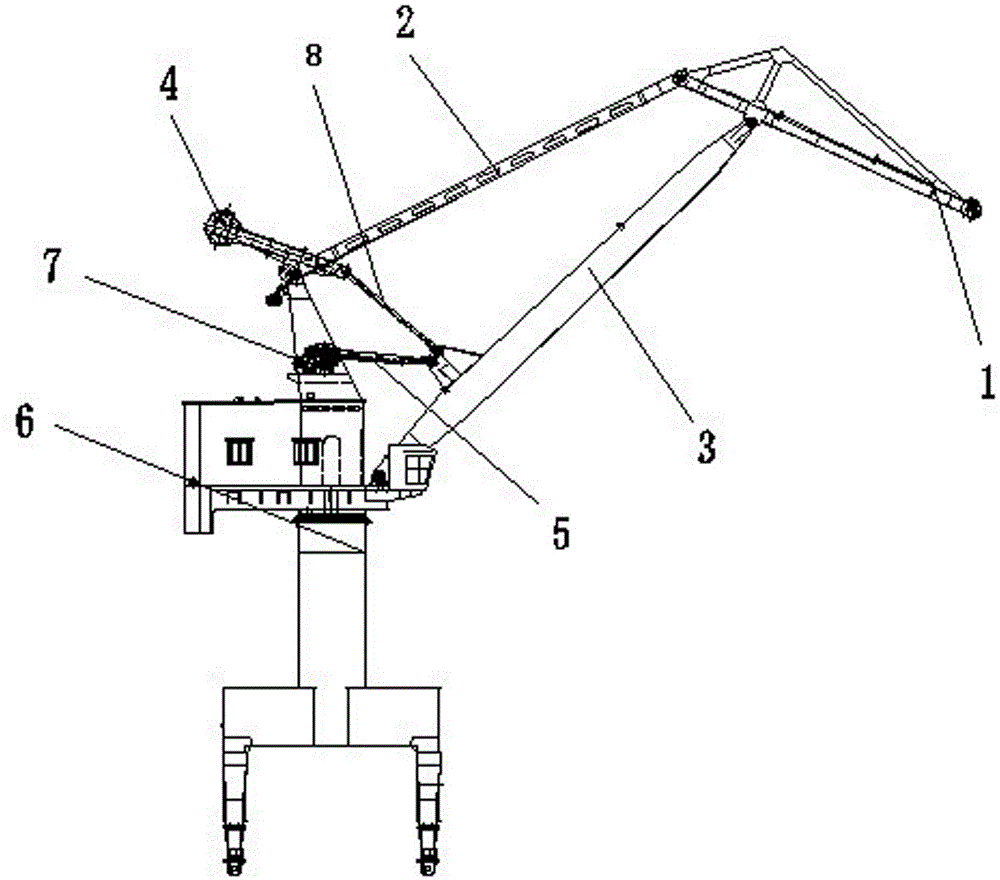

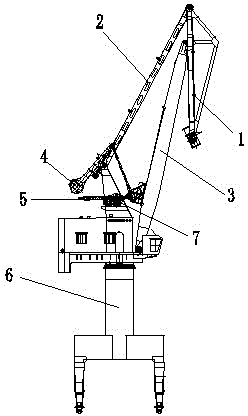

[0026] see figure 1 and figure 2 , In this embodiment, the door machine includes a base 6, a rack 5, a counterweight 4, a jib and a luffing motor 7.

[0027] In this embodiment, the jib includes an elephant trunk beam 1, an upper string frame 2 and a lower string frame 3, and the upper string frame 2 and the lower string frame 3 are both movably connected with the elephant trunk beam 1, and the upper string frame 2 and the lower string frame 3 are all movably connected on the abutment 6 . One end of the rack 5 is connected to the lower string frame 3, and the rack 5 is driven by the luffing motor 7.

[0028] In this embodiment, the balance point detection device for the counterweight 4 of the door machine includes a PLC, a frequency converter, a luffing motor 7 , a counterweight 4 , a jib and a base 6 .

[0029] In this embodiment, the PLC and the frequency converter communicate through the field bus, the frequency converter is electrically connected to the luffing motor 7...

Embodiment 2

[0040] In this embodiment, the method for detecting the balance point of the counterweight of the door machine includes the following steps.

[0041] 1) When the door operator is in the no-load state, control the arm frame of the door operator to shrink inward to the minimum position; start timing, and it is 0ms at this time.

[0042] 2) Control the outward movement of the jib at a constant speed; the speed is controlled at 5 m / min.

[0043] 3) Record the current value of the luffing motor 7 every 500 milliseconds; get Table 2.

[0044] Table 2: Current recording table.

[0045] time (ms) Current (A) 0 55.00 5000 55.34 10000 55.45 15000 55.51 20000 56.05 25000 56.96 30000 57.31 35000 58.12 40000 58.32 45000 58.50 50000 58.86 55000 59.56 60000 59.57 65000 60.20 70000 60.43 75000 60.80 80000 61.10 85000 61.27 90000 61.47 95000 62.08 100000 62.26 105000 62.66...

Embodiment 3

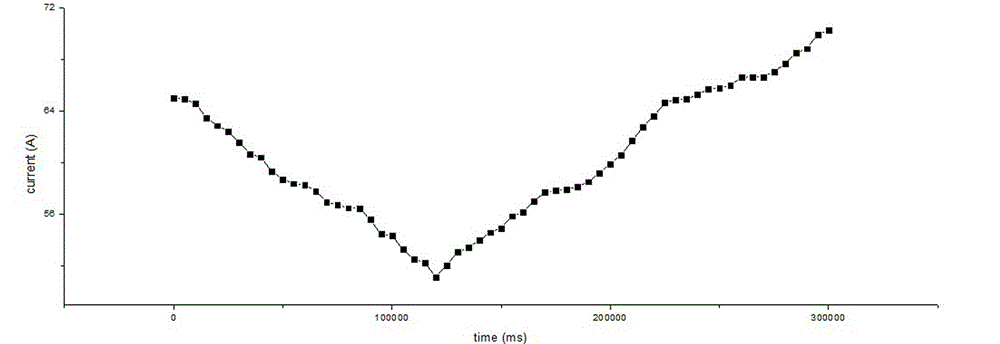

[0049] In this embodiment, the method for detecting the balance point of the counterweight of the door machine includes the following steps.

[0050] 1) When the door operator is in an unloaded state, control the arm frame of the door operator to shrink inward to the minimum position; start timing.

[0051] 2) Control the outward movement of the jib at a constant speed; the speed is controlled at 5 m / min.

[0052] 3) Record the current value of the luffing motor 7 every 500 milliseconds; get Table 3.

[0053] Table 3: Current recording table.

[0054] time (ms) Current (A) 0 80.00 5000 79.96 10000 79.76 15000 79.74 20000 79.37 25000 78.98 30000 78.96 35000 78.51 40000 78.10 45000 77.86 50000 77.44 55000 77.24 60000 77.08 65000 76.81 70000 76.33 75000 76.07 80000 75.80 85000 75.55 90000 75.24 95000 74.95 100000 74.64 105000 74.55 110000 74.20 11500...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com