Industrialization production method of 2-mercapto-1-methylimidazole

A technology of methylimidazole and its production method, which is applied in the field of industrialized production, can solve the problems of not finding a synthesis scheme of 2-mercapto-1-methylimidazole, and not giving a synthesis scheme of 2-mercapto-1-methylimidazole, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

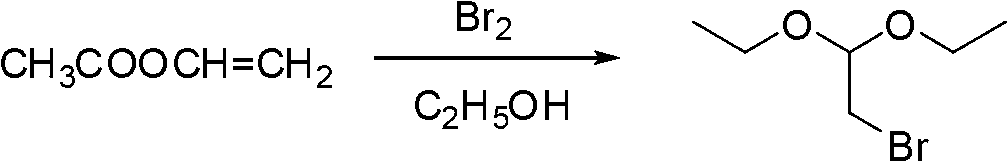

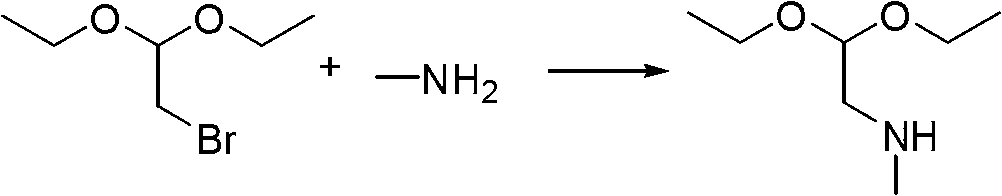

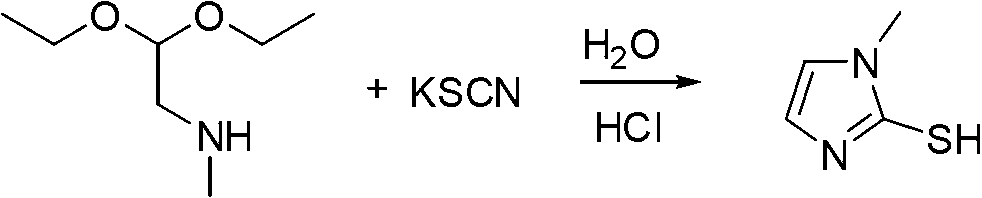

Method used

Image

Examples

Embodiment 1

[0019] (a) Pump 480 kg of absolute ethanol and 180 kg of vinyl acetate into the No. 1 reactor. After the pumping is completed, nitrogen balances the vacuum in the reactor. During the reaction process, the temperature of the reaction solution was controlled at about 5°C, and 335 kg of bromine was pressed into the No. 1 reactor, and the addition was completed in about 10 hours. After the addition of bromine, the temperature was raised to 30°C, and the reaction was kept until the reaction liquid was sampled and GC detected that the intermediate was ≤ 1.0%, that is, the reaction was stopped.

[0020] Under stirring, transfer the pre-prepared 16.7% sodium carbonate aqueous solution into the No. 1 reaction kettle until the pH of the reaction solution is 8, then add 540 kg of dichloromethane, stir for 30 minutes, and separate the organic layer.

[0021] Add 300 kilograms of water and 60 kilograms of sodium chloride in No. 2 reactor, after stirring and dissolving completely, then add ...

Embodiment 2

[0027] (a) Pump 480 kg of absolute ethanol and 180 kg of vinyl acetate into the No. 1 reactor. After the pumping is completed, nitrogen balances the vacuum in the reactor. During the reaction process, the temperature of the reaction solution was controlled at about 5°C, and 335 kg of bromine was pressed into the No. 1 reactor, and the addition was completed in about 10 hours. After the addition of bromine, the temperature was raised to 30°C, and the reaction was kept until the reaction liquid was sampled and GC detected that the intermediate was ≤ 1.0%, that is, the reaction was stopped.

[0028] Under stirring, transfer the pre-prepared 16.7% sodium carbonate aqueous solution into the No. 1 reaction kettle until the pH of the reaction solution is 10, then add 540 kg of dichloromethane, stir for 30 minutes, and separate the organic layer.

[0029] Add 300 kilograms of water and 60 kilograms of sodium chloride in No. 2 reactor, after stirring and dissolving completely, then add...

Embodiment 3

[0035] (a) Pump 480 kg of absolute ethanol and 180 kg of vinyl acetate into the No. 1 reactor. After the pumping is completed, nitrogen balances the vacuum in the reactor. During the reaction process, the temperature of the reaction solution was controlled at about 5°C, and 335 kg of bromine was pressed into the No. 1 reactor, and the addition was completed in about 10 hours. After the addition of bromine, the temperature was raised to 30°C, and the reaction was kept until the reaction liquid was sampled and GC detected that the intermediate was ≤ 1.0%, that is, the reaction was stopped.

[0036] Under stirring, transfer the pre-prepared 16.7% sodium carbonate aqueous solution into the No. 1 reaction kettle until the pH of the reaction solution is 9, then add 540 kg of dichloromethane, stir for 30 minutes, and separate the organic layer.

[0037] Add 300 kilograms of water and 60 kilograms of sodium chloride in No. 2 reactor, after stirring and dissolving completely, then add ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com