Full-bolt splicing node for inner sleeve slotted closed-section pillar

An inner sleeve and bolt technology, applied in the direction of construction and building structure, can solve problems such as prolonging construction time and unfavorable on-site construction, and achieve the effects of convenient design and installation, easy operation, and increased friction bearing capacity.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

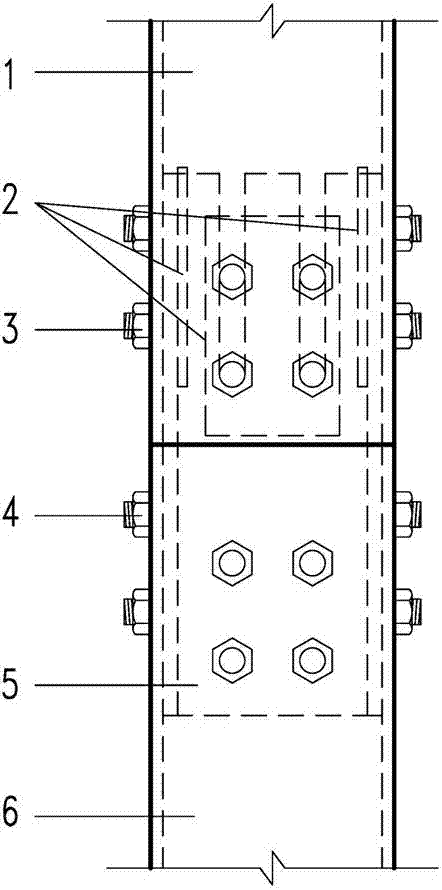

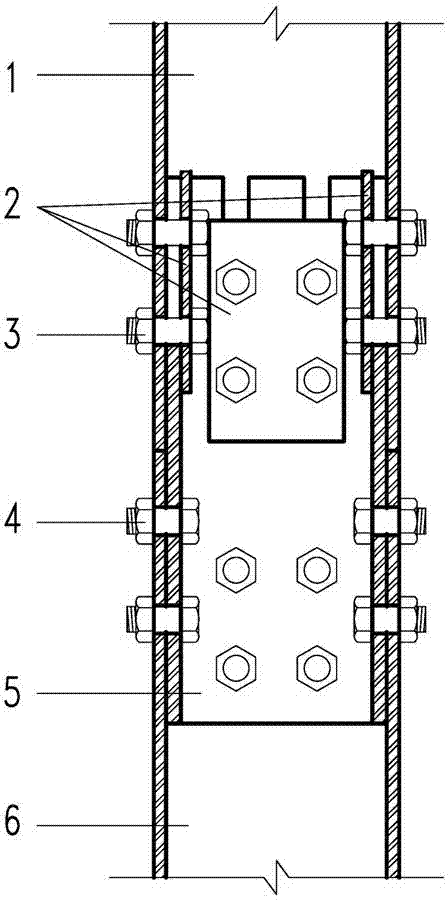

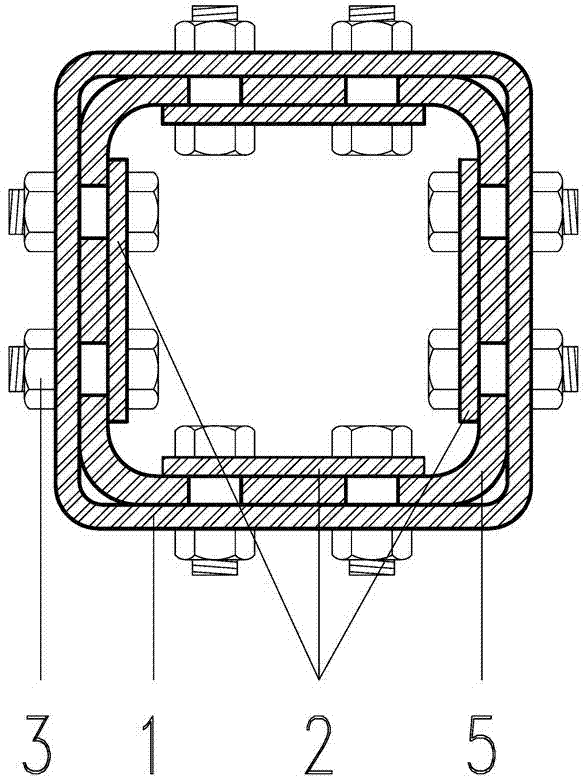

[0027] The technical scheme of the present invention will be further described below in conjunction with the drawings.

[0028] The invention provides a jointing scheme for a closed-section steel pipe column without welded seam full bolts and less nodes protruding from connected components.

[0029] The node of the invention is composed of two connected closed-end section columns, an inner sleeve, an inner lining plate and bolts. Such as figure 1 - Image 6 As shown, where: 1 is the upper steel pipe column, 2 is the inner liner, 3 is the upper column fastening bolt, 4 is the lower column fastening bolt, 5 is the inner sleeve, 6 is the lower steel pipe column, 7 is the upper and lower For the bolt holes on the column, 8 is a groove section on the inner sleeve, and 9 is a bolt hole on the inner sleeve. The inner sleeve 5 is used as a splicing member to connect the lower steel pipe column 1 and the upper steel pipe column 6. The inner sleeve 5 is fastened to the lower steel pipe co...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com